Abstract

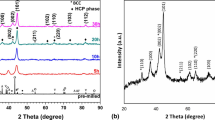

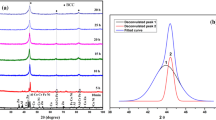

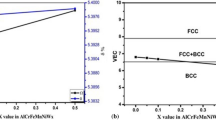

In this investigation, we have reported the alloying behavior, phase evolution, and thermal stability of equiatomic AlCoCrFeNiTi high-entropy alloy (HEA). The 40 h milled powder shows good chemical homogeneity with agglomerated particles varying in the range of ∼3–18 μm. The formation of a nanostructured single-phase BCC (a = 2.85 ± 0.01 Å) was observed along with the minor tungsten carbide (WC) phase that formed due to contamination during milling. Thermal stability of the alloy has been studied using dynamic differential scanning calorimetry (DSC) thermogram and in situ X-ray diffraction. It has been found that this HEA is stable up to 600 °C (873 K). Consolidated samples at 1000 °C (1273 K) showed the transformation of body centered cubic (BCC) phase into the B2 (a = 2.87 ± 0.03 Å) phase co-existing with minor hexagonal WC (a = 2.90 Å, c = 2.83 Å) phase.

Similar content being viewed by others

Change history

01 January 2020

An Erratum to this paper has been published: https://doi.org/10.1557/jmr.2019.314

References

B. Cantor, I.T.H. Chang, P. Knight, and A.J.B. Vincent: Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng., A 375–377, 213–218 (2004).

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang: Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 6, 299–303 (2004).

N.K. Mukhopadhyay: High entropy alloys: A renaissance in physical metallurgy. Curr. Sci. 109, 665–667 (2015).

J.W. Yeh: Alloy design strategies and future trends in high-entropy alloys. JOM 65, 1759–1771 (2013).

S.H. Joo, H. Kato, M.J. Jang, J. Moon, E.B. Kim, S.J. Hong, and H.S. Kim: Structure and properties of ultrafine-grained CoCrFeMnNi high-entropy alloys produced by mechanical alloying and spark plasma sintering. J. Alloys Compd. 698, 591–604 (2017).

S. Mohanty, T.N. Maity, S. Mukhopadhyay, S. Sarkar, N.P. Gurao, S. Bhowmick, and K. Biswas: Powder metallurgical processing of equiatomic AlCoCrFeNi high entropy alloy: Microstructure and mechanical properties. Mater. Sci. Eng., A 679, 299–313 (2017).

I. Moravcik, J. Cizek, P. Gavendova, S. Sheikh, S. Guo, and I. Dlouhy: Effect of heat treatment on microstructure and mechanical properties of spark plasma sintered AlCoCrFeNiTi0.5 high entropy alloy. Mater. Lett. 174, 53–56 (2016).

Y. Zhang, T. Zuo, Y. Cheng, and P.K. Liaw: High-entropy alloys with high saturation magnetization, electrical resistivity, and malleability. Sci. Rep. 3, 1–7 (2013).

Y.L. Chou, J.W. Yeh, and H.C. Shih: The effect of molybdenum on the corrosion behaviour of the high-entropy alloys Co1.5CrFeNi1.5Ti0.5Mox in aqueous environments. Corros. Sci. 52, 2571–2581 (2010).

W. Kai, C.C. Li, F.P. Cheng, K.P. Chu, R.T. Huang, L.W. Tsay, and J.J. Kai: The oxidation behavior of an equimolar FeCoNiCrMn high-entropy alloy at 950 °C in various oxygen-containing atmospheres. Corros. Sci. 108, 209–214 (2016).

Z. Fu, W. Chen, Z. Jiang, B.E. MacDonald, Y. Lin, F. Chen, L. Zhang, and E.J. Lavernia: Influence of Cr removal on the microstructure and mechanical behaviour of a high-entropy Al0.8Ti0.2CoNiFeCr alloy fabricated by powder metallurgy. Powder Metall. 61, 106–114 (2018).

K. Zhang and Z. Fu: Intermetallics effects of annealing treatment on properties of CoCrFeNiTiAlx multi-component alloys. Intermetallics 28, 34–39 (2012).

S. Varalakshmi, M. Kamaraj, and B.S. Murty: Synthesis and characterization of nanocrystalline AlFeTiCrZnCu high entropy solid solution by mechanical alloying. J. Alloys Compd. 460, 253–257 (2008).

Y.P. Wang, B.S. Li, M.X. Ren, C. Yang, and H.Z. Fu: Microstructure and compressive properties of AlCrFeCoNi high entropy alloy. Mater. Sci. Eng., A 491, 154–158 (2008).

Y.L. Chen, Y.H. Hu, C.A. Hsieh, J.W. Yeh, and S.K. Chen: Competition between elements during mechanical alloying in an octonary multi-principal-element alloy system. J. Alloys Compd. 481, 768–775 (2009).

Z. Fu, W. Chen, Z. Chen, H. Wen, and E.J. Lavernia: Influence of Ti addition and sintering method on microstructure and mechanical behavior of a medium-entropy Al0.6CoNiFe alloy. Mater. Sci. Eng., A 619, 137–145 (2014).

C. Suryanarayana, E. Ivanov, and V. Boldyrev: The science and technology of mechanical alloying. Mater. Sci. Eng., A 304, 151–158 (2001).

C. Suryanarayana: Mechanical alloying and milling. Prog. Mater. Sci. 46, 1–184 (2001).

Z. Fu, W. Chen, H. Wen, D. Zhang, Z. Chen, B. Zheng, Y. Zhou, and E.J. Lavernia: Microstructure and strengthening mechanisms in an FCC structured single-phase nanocrystalline Co25Ni25Fe25Al7.5Cu17.5 high-entropy alloy. Acta Mater. 107, 59–71 (2016).

Z. Fu, W. Chen, H. Wen, Z. Chen, and E.J. Lavernia: Effects of Co and sintering method on microstructure and mechanical behavior of a high-entropy Al0.6NiFeCrCo alloy prepared by powder metallurgy. J. Alloys Compd. 646, 175–182 (2015).

C.C. Koch: Nanocrystalline high-entropy alloys. Mater. Res. Lett. 32, 3435–3444 (2017).

K.B. Zhang, Z.Y. Fu, J.Y. Zhang, W.M. Wang, S.W. Lee, and K. Niihara: Characterization of nanocrystalline CoCrFeNiTiAl high-entropy solid solution processed by mechanical alloying. J. Alloys Compd. 495, 33–38 (2010).

K.B. Zhang, Z.Y. Fu, J.Y. Zhang, W.M. Wang, H. Wang, Y.C. Wang, Q.J. Zhang, and J. Shi: Microstructure and mechanical properties of CoCrFeNiTiAlx high-entropy alloys. Mater. Sci. Eng., A 508, 214–219 (2009).

P. Veronesi, E. Colombini, R. Rosa, C. Leonelli, and F. Rosi: Microwave assisted synthesis of Si-modified Mn25FexNi25Cu(50−x) high entropy alloys. 162, 277–280 (2016).

E. Thostenson and T.W. Chu: Microwave processing: Fundamentals and applications. 30, 1055–1071 (1999).

W. Chen, Z. Fu, S. Fang, H. Xiao, and D. Zhu: Alloying behavior, microstructure and mechanical properties in a FeNiCrCo0.3Al0.7 high entropy alloy. Mater. Des. 51, 854–860 (2013).

V. Shivam, J. Basu, Y. Shadangi, M.K. Singh, and N.K. Mukhopadhyay: Mechano-chemical synthesis, thermal stability and phase evolution in AlCoCrFeNiMn high entropy alloy. J. Alloys Compd. 757, 87–97 (2018).

V. Shivam, J. Basu, V.K. Pandey, Y. Shadangi, and N.K. Mukhopadhyay: Alloying behaviour, thermal stability and phase evolution in quinary AlCoCrFeNi high entropy alloy. Adv. Powder Technol. 29, 2221–2230 (2018).

C. Wang, W. Ji, and Z. Fu: Mechanical alloying and spark plasma sintering of CoCrFeNiMnAl high-entropy alloy. Adv. Powder Technol. 25, 1334–1338 (2014).

Y.X. Zhuang, H.D. Xue, Z.Y. Chen, Z.Y. Hu, and J.C. He: Effect of annealing treatment on microstructures and mechanical properties of FeCoNiCuAl high entropy alloys. Mater. Sci. Eng., A 572, 30–35 (2013).

N.H. Tariq, M. Naeem, B.A. Hasan, J.I. Akhter, and M. Siddique: Effect of W and Zr on structural, thermal and magnetic properties of AlCoCrCuFeNi high entropy alloy. J. Alloys Compd. 556, 79–85 (2013).

B.Y. Zhang, Y.J. Zhou, J.P. Lin, G.L. Chen, and P.K. Liaw: Solid-solution phase formation rules for multi-component alloys, Adv. Eng. Mater. 6, 534–538 (2008).

X. Yang and Y. Zhang: Prediction of high-entropy stabilized solid-solution in multi-component alloys. Mater. Chem. Phys. 132, 233–238 (2012).

A.R. Miedema, P.F. de Châtel, and F.R. de Boer: Cohesion in alloys—Fundamentals of a semi-empirical model. Physica B + C 100, 1–28 (1980).

J. Basu, B.S. Murty, and S. Ranganathan: Glass forming ability: Miedema approach to (Zr, Ti, Hf)–(Cu, Ni) binary and ternary alloys. J. Alloys Compd. 465, 163–172 (2008).

Author information

Authors and Affiliations

Corresponding author

Supplementary Material

Rights and permissions

About this article

Cite this article

Shivam, V., Shadangi, Y., Basu, J. et al. Alloying behavior and thermal stability of mechanically alloyed nano AlCoCrFeNiTi high-entropy alloy. Journal of Materials Research 34, 787–795 (2019). https://doi.org/10.1557/jmr.2019.5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2019.5