Abstract

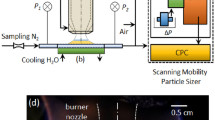

Earlier publications describe the counterflow diffusion flame burner and its unique capability to produce oxide particles having certain structures, such as spheres of one material coated with another, spheres of one composition with attached bulbs of another composition, and uniform multicomponent mixtures. Here we describe the production and properties of bulk quantities of powders produced using this burner. Measurements were made of specific surface area and, for titania, of phase composition. It was found that the controls over powder characteristics used in other forms of flame-synthesis are equally effective in the counterflow diffusion flame burner. We found that the specific surface area of both silica and titania powders decrease with increasing precursor concentrations. Transmission electron microscopy analysis of the titania powders indicates that the mean size of the particles that comprise these powders increases with increasing concentration. These trends are consistent with the collision-coalescence theory of particle growth. In addition, the crystalline phase of titania can be controlled by selecting the appropriate feed stream. For example, over the ranges TiCl4 precursor concentrations tested, feeding it only into the oxidizer stream yields mainly anatase TiO2 powders, while feeding only into the fuel stream yields mainly rutile TiO2 powders. These trends can be explained by the known atmosphere-dependent anatase-rutile transformation. The present data demonstrate that, in addition to its unique capability to produce certain particle shapes and morphologies, the counterflow diffusion flame burner can be manipulated to produce either of the major commercial titania phases, and also silica, with a wide range of specific surface areas.

Similar content being viewed by others

References

J. H. Braun, A. Baidins, and R. E. Marganski, Prog. Org. Coat. 20, 105 (1992).

G. C. Bond and S. F. Tahir, Appl. Catal. 71, 1 (1991).

C-H. Hung and J. L. Katz, J. Mater. Res. 7, 1861 (1992).

C-H. Hung, P. F. Miquel, and J.L. Katz, J. Mater. Res. 7, 1870 (1992).

J. L. Katz and P. F. Miquel, Nanostructured Mater. 4, 551 (1994).

P. F. Miquel, C-H. Hung, and J.L. Katz, J. Mater. Res. 8, 2404 (1993).

P. F. Miquel and J. L. Katz, J. Mater. Res. 9, 746 (1994).

M. R. Zachariah, D. Chin, H. G. Semerjian, and J. L. Katz, Appl. Opt. 28, 530 (1989).

M. R. Zachariah and R. G. Joklik, J. Appl. Phys. 68, 321 (1990).

M. R. Zachariah, Chemistry of silane oxidation and pyrolysis during particle formation: Comparison with in situ measurements, Proceedings of the Western States Section of the Combustion Institute, March 1991 Meeting.

S. L. Chung and J. L. Katz, Combustion and Flame 61, 271 (1985).

J. L. Katz and C. H. Hung, U.S. Patent 5268 337.

A. Gomez and D. E. Rosner, Combustion Sci. Technol. 89, 335 (1993).

P. F. Miquel, Flame Synthesis of Nanostructured Mixed Oxides and Its Application to the Formation of Catalysts, Ph.D. Thesis, The Johns Hopkins University, Baltimore, MD (1995).

M. Formenti, F. Juillet, P. Meriaudeau, S.J. Teichner, and P. Vergnon, in Aerosols and Atmospheric Chemistry, edited by G. M. Hidy (Academic Press, New York, 1972), p. 45.

A. P. George, R. D. Murley, and E. R. Place, in Fogs and Smokes, Symposium of the Faraday Society (Chemical Society, London, 1973), p. 63.

G. D. Ulrich, Comb. Sci. Tech. 4, 47–57 (1971).

R. D. Shannon and J. A. Pask, Am. Minerol. 49, 1707 (1964).

S. Hishita, I. Mutoh, K. Koumota, and H. Yanagida, Ceram. Int. 9, 61 (1983).

K. J.D. Mackenzie and P.J. Melling, Trans. J. Brit. Ceram. Soc. 73, 23 (1974).

A. Kobata, K. Kusakabe, and S. Morooka, AIChE J. 37, 347 (1991).

M. K. Akhtar, Y. Xiong, and S.E. Pratsinis, AIChE J. 37, 1561 (1991).

K. P. Kumar, V. T. Zaspalis, F.F.M. De Mul, K. Keizer, and A. J. Burggraff, in Better Ceramics Through Chemistry V, edited by M. J. Hampden-Smith, W. G. Klemperer, and C. J. Brinker (Mater. Res. Soc. Symp. Proc. 271, Pittsburgh, PA, 1992), pp. 499–504.

Y. Iida and S. Ozaki, J. Am. Ceram. Soc. 44, 120 (1961).

R. D. Shannon and J. A. Pask, J. Am. Ceram. Soc. 48, 391 (1965).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Rulison, A.J., Miquel, P.F. & Katz, J.L. Titania and silica powders produced in a counterflow diffusion flame. Journal of Materials Research 11, 3083–3089 (1996). https://doi.org/10.1557/JMR.1996.0392

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.1996.0392