Abstract

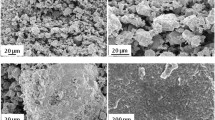

Measurements of x-ray diffraction (XRD) profiles have been performed on commercially pure Fe and Al powders, cryomilled Fe–3 wt.% Al powders, cold pressed (CP) pure Fe and Al, hot pressed (HP) and hot isostatically pressed (HIP) Fe–3 wt.% Al. Scherrer equation (SE), integral breadth analysis (IBA), and single-line approximation (SLA) methods have been employed to extract grain size and microstrain. The results demonstrate that, in the case of the cryomilled nanocrystalline Fe–3 wt.% Al powders, all these XRD techniques yielded reasonable, consistent grain size results. However, discrepancies were found in cold pressed (CP-Fe), hot pressed (HP-Fe–3 wt.% Al), and hot isostatically pressed (HIP-Fe–3 wt.% Al) samples. TEM imaging revealed the presence of a certain density of dislocations inside the grains in the HP-Fe–3 wt.% Al and HIP-Fe–3 wt.% Al, which is thought to be partly or fully responsible for the observed discrepancies.

Similar content being viewed by others

References

H. Gleiter, Prog. Mater. Sci. 33, 223 (1989).

C. Suryanarayana, Int. Mater. Rev. 40, 41 (1995).

H. Gleiter, Deformation of Polycrystals: Mechanisms and Microstructures, edited by N. Hansen et al. (Riso National Laboratory, Roskïlde, Denmark, 1981), p. 15.

R. W. Siegel, Processing of Metals and Alloys, Materials Science and Technology, edited by R.W. Cahn (VCH, Weinheim, Germany, 1991), Vol. 15, p. 583.

R. Birringer, H. Gleiter, H. P. Klein, and P. Marquart, Phys. Lett. 102A, 365 (1984).

C. C. Koch, Nanostructured Mater. 2, 109 (1993).

E. Hellstern, H. J. Fecht, Z. Fu, and W. L. Johnson, J. Mater. Res. 4, 1292 (1989).

K. Lu, W.D. Wei, and J.T. Wang, J. Appl. Phys. 69, 7345 (1991).

G. Palumbo, S. J. Thorpe, and K. T. Aust, Scripta Metall. Mater. 24, 1347 (1990).

C. H. Chou and J. Phillips, J. Mater. Res. 7, 2107 (1992).

V. L. Tellkamp, M. L. Lau, A. Fabel, and E.J. Lavernia, Nano-Structured Mater. 9, 489 (1997).

J. Weissmuller, Synthesis and Processing of Nanocrystalline Powder, edited by D. L. Bourell (The Minerals, Metals & Materials Society, 1996).

R. Bohn, M. Oehring, Th. Pfullmann, F. Appel, and R. Bormann, Processing and Properties of Nanocrystalline Materials, edited by C. Suryanarayana, J. Singh, and F. H. Froes (The Mineral, Metals & Materials Society, 1996), p. 355.

R. W. Siegel, S. Ramasamy, H. Hahn, Z.Q. Li, and T. Lu, J. Mater. Res. 3, 1367 (1988).

H. P. Klug and L. E. Alexander, X-ray Diffraction Procedures (John Wiley & Sons, New York, 1974), p. 643.

P. Scherrer, Nachr. Ges. Wiss. Goettingen, Math. Phys. K1 (2), 98 (1918).

Th.H. de Keijser, J. I. Langford, E.J. Mittemeijer, and A. B. P. Vogels, J. Appl. Crystallogr. 15, 308 (1982).

B.E. Warren and B.L. Averbach, J. Appl. Phys. 21, 595 (1950).

G.K. Williamson and W.H. Hall, Acta Metall. 1, 22 (1953).

C.N.J. Wagner and E. N. Aqua, Advances in X-ray Analysis (Plenum Press, New York, 1964), Vol. 7, p. 46.

R.K. Gupta and T. R. Anantharaman, Z. Metallkd. 62, 732 (1971).

L. He and E. Ma, J. Mater. Res. 11, 72 (1996).

S.K. Pradhan, T. Chakraborty, S. P. Sen Gupta, C. Suryanarayana, A. Frefer, and F. H. Froes, NanoStructured Mater. 5, 53 (1995).

M. Hoffmann and R. Birringer, Acta Mater. 44, 2729 (1996).

C.P. Dogan, J. C. Rawers, R. D. Govier, and G. Korth, Nano-Structured Mater. 4, 631 (1994).

G.W. Nieman, Ph.D. Thesis, Northwestern University, Evanston, IL (1991).

R.J. Perez, H. G. Jiang, and E. J. Lavernia, NanoStructured Mater. 9, 71 (1997).

R. J. Perez, B. Huang, and E.J. Lavernia, NanoStructured Mater. 7, 565 (1996).

M. L. Lau, H. G. Jiang, R. J. Perez, J. Juarez-Islas, and E. J. Lavernia, NanoStructured Mater. 7, 847 (1996).

A. J. C. Wilson, X-ray Optics (Methuen, London, 1949), p. 65.

J. I. Langford, J. Appl. Crystallogr. 11, 10 (1978).

T.B. Massalski, Binary Alloy Phase Diagrams (ASM INTERNATIONAL, Materials Park, OH, 1990).

T.R. Malow and C. C. Koch, Synthesis and Processing of Nanocrystalline Powder, edited by D. L. Bourell (The Minerals, Metals & Materials Society, 1996), p. 33.

H. Ouyang, B. Fultz, and H. Kuwano, Nanophases and Nanocrystalline Structures, edited by R. D. Shull and J.M. Sanchez (TMS, Warrendale, PA, 1994), p. 95.

B. Fultz, H. Kuwano, and H. Ouyang, J. Appl. Phys. 76, 5691 (1994).

J. Rawers, J. Groza, and G. Korth, Synthesis and Processing of Nanocrystalline Powder, edited by D.L. Bourell (The Minerals, Metals & Materials Society, 1996), p. 163.

D.M. Goodrich and M. Atzmon, Proceedings of the International Symposium on Metastable, Mechanically Alloyed and Nanocrystalline Materials, edited by R. Schulz, Quebec, 1995.

H.G. Jiang and E. J. Lavernia, unpublished results.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Jiang, H.G., Rühle, M. & Lavernia, E.J. On the applicability of the x-ray diffraction line profile analysis in extracting grain size and microstrain in nanocrystalline materials. Journal of Materials Research 14, 549–559 (1999). https://doi.org/10.1557/JMR.1999.0079

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.1999.0079