Abstract

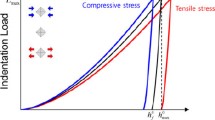

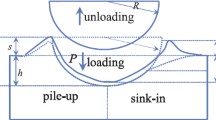

A new experimental technique is presented for making measurements of biaxial residual stress using load and depth sensing indentation (nanoindentation). The technique is based on spherical indentation, which, in certain deformation regimes, can be much more sensitive to residual stress than indentation with sharp pyramidal indenters like the Berkovich. Two different methods of analysis were developed: one requiring an independent measure of the material’s yield strength and the other a reference specimen in the unstressed state or other known reference condition. Experiments conducted on aluminum alloys to which controlled biaxial bending stresses were applied showed that the methods are capable of measuring the residual stress to within 10–20% of the specimen yield stress. Because the methods do not require imaging of the hardness impressions, they are potentially useful for making localized measurements of residual stress, as in thin films or small volumes, or for characterization of point-to-point spatial variations of the surface stress.

Similar content being viewed by others

References

S. Kokubo, Science Reports of the Tohoku Imperial University 21, 256 (1932).

H. Kostron, Technisches Versuchsant Mitteilungen January, 17 (1932).

H. Kostron, Metallwirtschaft 12, 473 (1933).

G. Sines and R. Carlson, ASTM Bulletin 180, 35 (1952).

P.A. Blain, Sheet Metal Ind. 26, 135 (1949).

P.A. Blain, Metal. Progress, 99 (1957).

J.O. Alamen, Prod. Eng., 121 (1950).

G.U. Oppel, Exp. Mech. 21, 135 (1964).

T.R. Simes, S.G. Mellor, and D.A. Hills, J. Strain Anal. 19, 135 (1984).

F.H. Vitovec, in Microindentation Techniques in Materials Science and Engineering, edited by P.J. Blau and B.R. Lawn (ASTM 889, Philadelphia, PA, 1986), p. 175.

W.R. LaFontain, B. Yost, and C-Y. Li, J. Mater. Res. 5, 776 (1990).

M.F. Doerner, D.S. Gardner, and W.D. Nix, J. Mater. Res. 1, 845 (1986).

T.Y. Tsui, W.C. Oliver, and G.M. Pharr, J. Mater. Res. 11, 752 (1996).

A. Bolshakov, W.C. Oliver, and G.M. Pharr, J. Mater. Res. 11, 760 (1996).

A. Bolshakov and G.M. Pharr, J. Mater. Res. 13, 1049 (1998).

S. Suresh and A.E. Giannakopoulos, Acta Mater. 46, 5755 (1998).

B. Taljat and G.M. Pharr, in Thin Films: Stresses and Mechanical Properties VIII, edited by R. Vinci, O. Kraft, N. Moody, and E. Shaffer II (Mater. Res. Soc. Symp. Proc. 594, Warrendale, PA, 2000), p. 519.

K.L. Johnson, J. Mech. Phys. Solids 18, 115 (1970).

K.L. Johnson, Contact Mechanics (Cambridge University Press, Cambridge, United Kingdom, 1985).

H. Hertz, Miscellaneous Papers, edited by D.E. Jones and G.H. Schott (Macmillan, London, 1896), p. 163.

D. Tabor, The Hardness of Metals (Clarendon Press, Oxford, United Kingdom, 1951).

H.A. Francis, J. Eng. Mater. Technol. 98, 272 (1976).

Y. Tirupataiah and G. Sundararajan, Metall. Trans. A 22A, 2375 (1991).

The Aluminum Association, Aluminum Standards and Data (The Aluminum Association, New York, 1968), p. 28.

J.G. Swadener and G.M. Pharr, in Thin Films: Stresses and Mechanical Properties VII, edited by R. Vinci, O. Kraft, N. Moody, and E. Shaffer VIII (Mater. Res. Soc. Symp. Proc. 594, Warrendale, PA, 2000), p. 525.

J.G. Swadener and G.M. Pharr, Philos. Mag. A 81, 447 (2001).

J.S. Field and M.V. Swain, J. Mater. Res. 8, 297 (1993).

W.C. Oliver and G.M. Pharr, J. Mater. Res. 7, 1564 (1992).

Z. Mroz (private communication, Chicago, IL, August 31, 2000).

A.L. Norbury and T. Samuel, J. Iron Steel Inst. 117, 673 (1928).

B. Taljat, T. Zacharia, and G.M. Pharr in Fundamentals of Nanoindentation and Nanotribology, edited by N.R. Moody, W.W. Gerberich, N. Burnham, and S.P. Baker (Mater. Res. Soc. Symp. Proc. 522, Warrendale, PA, 1998), p. 33.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Swadener, J.G., Taljat, B. & Pharr, G. Measurement of residual stress by load and depth sensing indentation with spherical indenters. Journal of Materials Research 16, 2091–2102 (2001). https://doi.org/10.1557/JMR.2001.0286

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2001.0286