Abstract

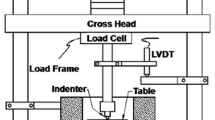

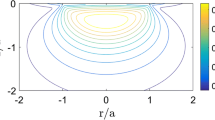

The ball indentation technique has the potential to be an excellent substitute for a standard tensile test, especially in the case of small specimens or property-gradient materials such as welds. In our study, the true stress–true strain relationships of steels with different work-hardening exponents (0.1–0.3) were derived from ball indentations. Four kinds of strain definitions in indentation were attempted: 0.2sinγ, 0.4hc/a, ln[2/(1 + cosγ)], and 0.1tanγ. Here, γ is the contact angle between the indenter and the specimen, hc is the contact depth, and a is the contact radius. Through comparison with the standard data measured by uniaxial tensile testing, the best strain definition was determined to be 0.1tanγ. This new definition of strain, in which tanγ means the shear strain at contact edge, reflected effectively the work-hardening characteristics. In addition, the effects of pileup or sink-in were considered in determining the real contact between the indenter and the specimen from the indentation load–depth curve. The work-hardening exponent was found to be a main factor affecting the pileup/sink-in phenomena of various steels. These phenomena influenced markedly the absolute values of strain and stress in indentation by making the simple traditional relationship Pm/σR ≈ ≈ 3 valid for the fully plastic regime.

Similar content being viewed by others

References

J. Menčík and M.V. Swain, Mater. Forum 18, 277 (1994).

D. Tabor, The Hardness of Metals (Clarendon Press, Oxford, United Kingdom, 1951).

D.M. Marsh, Proc. R. Soc. London, Ser. A 279, 420 (1964).

C-H. Mok, Exp. Mech. Feb, 87 (1966).

R.A. George, S. Dinda, and A.S. Kasper, Met. Progress May, 30 (1976).

D. Kramer, H. Huang, M. Kriese, J. Robach, J. Nelson, A. Wright, D. Bahr, and W.W. Gerberich, Acta Mater. 47, 333 (1999).

J.H. Underwood, G.P. O’Hara, and J.J. Zalinka, Exp. Mech. Dec, 379 (1986).

H.A. Francis, Trans. ASME (Series H) 9, 272 (1976).

F.M. Haggag, in Small Specimen Test Techniques Applied to Nuclear Reactor Vessel Thermal Annealing and Plant Life Extension, edited by W.R. Corwin, F.M. Haggag, and W.L. Server (American Society for Testing and Materials, Philadelphia, PA, 1993), pp. 27–44.

J.S. Field and M.V. Swain, J. Mater. Res. 10, 101 (1995).

A.C. Fischer-Cripps and B.R. Lawn, Acta Mater. 44, 519 (1996).

J. Alcalaá, A.E. Giannakopoulos, and S. Suresh, J. Mater. Res. 13, 1390 (1998).

B. Taljat, T. Zacharia, and F. Kosel, Int. J. Solids Structures 35, 4411 (1998).

M.F. Doerner and W.D. Nix, J. Mater. Res. 1, 601 (1986).

W.C. Oliver and G.M. Pharr, J. Mater. Res. 7, 1564 (1992).

I.N. Sneddon, Int. J. Eng. Sci. 3, 47 (1965).

J.R. Mattews, Acta Metall. 28, 311 (1980).

R. Hill, F.R.S., B. Storåkers, and A.B. Zdunek, Proc. R. Soc. London, Ser. A 423, 301 (1989).

K.L. Johnson, J. Mech. Phys. Solids 18, 115 (1970).

Yu.V. Milman, B.A. Galanov, and S.I. Chugunova, Acta Metall. Mater. 41, 2523 (1993).

K.L. Johnson, Contact Mechanics (Cambridge University Press, Cambridge, United Kingdom, 1985).

E. Meyer, Z. ver . Deutshe Ing. 52, 645 (1908).

W.W. Gerberich, S.K. Venkataraman, H. Huang, S.E. Harvey, and D.L. Kohlstedt, Acta Metall. Mater. 43, 1569 (1995).

A.B. Mann and J.B. Pethica, in Thin Films: Stresses and Mechani-cal Properties VI, edited by W.W. Gerberich, H. Gao, J-E. Sundgren, and S.P. Baker (Mater. Res. Soc. Symp. Proc. 436, Pittsburgh, PA, 1997), p. 153.

M. Hisaka, H. Ishitobi, and S. Kawata, J. Opt. Soc. Am. B 17, 1422 (2000).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ahn, JH., Kwon, D. Derivation of plastic stress–strain relationship from ball indentations: Examination of strain definition and pileup effect. Journal of Materials Research 16, 3170–3178 (2001). https://doi.org/10.1557/JMR.2001.0437

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2001.0437