Abstract

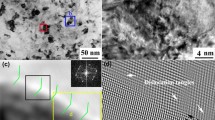

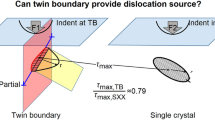

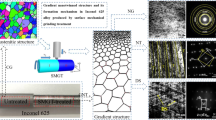

A nanostructured surface layer was formed on an Inconel 600 plate by subjecting it to surface mechanical attrition treatment at room temperature. Transmission electron microscopy and high-resolution transmission electron microscopy of the treated surface layer were carried out to reveal the underlying grain refinement mechanism. Experimental observations showed that the strain-induced nanocrystallization in the current sample occurred via formation of mechanical microtwins and subsequent interaction of the microtwins with dislocations in the surface layer. The development of high-density dislocation arrays inside the twin-matrix lamellae provides precursors for grain boundaries that subdivide the nanometer-thick lamellae into equiaxed, nanometer-sized grains with random orientations.

Similar content being viewed by others

References

C.C. Koch: The synthesis and structure of nanocrystalline materials produced by mechanical attrition. Nanostruct, Mater. 2, 109 (1993).

H.J. Fecht, in Nanophase Materials, edited by G.C. Hadjipanayis and R.W. Siegel (Kluwer Academic Publishers, Dordrecht, The Netherlands, 1994), p. 125.

N. Hansen: Cold deformation microstructures. MaterSci. Tech. 6, 1039 (1990).

Y.M. Wang, M.W. Chen, H.W. Sheng, and E. Ma: Nanocrystalline grain structures developed in commercial purity Cu by low-temperature cold rolling. J. Mater. Res. 17, 3004 (2002).

R.Z. Valiev, R.R. Mulyukov, V.V. Ovchinnikov, and V.A. Shabashov: Mossbauer analysis of submicrometer grained iron. Scr. Metall Mater. 25, 2717 (1991).

Y. Iwahashi, Z. Horita, M. Nemoto, and T.G. Langdon: The process of grain refinement in equal-channel angular pressing. Acta Mater. 46,3317(1998).

A.P. Zhilyaev, S. Lee, G.V. Nurislamova, R.Z. Valiev, and T.G. Langdon: Microhardness and microstructural evolution in pure nickel during high-pressure torsion. Scr. Mater. 44, 2753 (2001).

R.Z. Valiev and I.V. Alexandrov: Nanostructured materials from severe plastic deformation. Nanostruct. Mater. 12, 35 (1999).

N.R. Tao, M.L. Sui, J. Lu, and K. Lu: Surface nanocrystallization of iron induced by ultrasonic shot peening. Nanostruct. Mater. 11, 433 (1999).

W.P. Tong, N.R. Tao, Z.B. Wang, J. Lu, and K. Lu: Nitriding iron at lower temperatures. Science 299, 686 (2003).

N.R. Tao, Z.B. Wang, W.P. Tong, M.L. Sui, J. Lu, and K. Lu: An investigation of surface nanocrystallization mechanism in Fe induced by surface mechanical attrition treatment. Acta Mater. 50, 4603 (2002).

A. Belyakov, T. Sakai, H. Miura, and K. Tsuzaki: Grain refinement in copper under large strain deformation. Philos. Mag. A 81, 2629 (2001).

D.A. Hughes: Scaling of deformation-induced microstructures in fcc metals. Scr. Mater. 47, 697 (2002).

D.A. Hughes and N. Hansen: Microstructure and strength of nickel at large strains. Acta Metall. 48, 2985 (2000).

B. Bay, N. Hansen, D.A. Hughes, and D. Kuhlmann-Wilsdorf: Evolution off.c.c. deformation structures in polyslip. ActaMetal. 40, 205 (1992).

X. Wu, N. Tao, Y. Hong, B. Xu, J. Lu, and K. Lu: Microstructure and evolution of mechanically-induced ultrafine grain in surface layer of Al-alloy subjected to USSP. Acta Mater. 50, 2075 (2002).

D.H. Shin, I. Kim, J. Kim, and K.T Park: Grain refinement mechanism during equal-channel angular pressing of a low-carbon steel. Acta Mater. 49, 1285 (2001).

K Lu, J. Lu, Chinese Patent No. 01122980. 2 (2001); French Patent No. FR2812284 (2001).

J.M. Manero, F.J. Gil, and J.A. Planell: Deformation mechanisms of Ti—6Al—4V alloy with a martensitic microstructure subjected to oligocyclic fatigue. ActaMaten 48,3353(2000).

L.E. Murr, in Interfacial Phenomena in Metals and Alloys (Tech-books, Herndan, VA, 1975), p. 145.

M. Kumar, A.J. Schwartz, and W.E. King: Microstructural evolution during grain boundary engineering of low to medium stacking fault energy fcc materials. Acta Mater. 50, 2599 (2002).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tao, N.R., Wu, X.L., Sui, M.L. et al. Grain refinement at the nanoscale via mechanical twinning and dislocation interaction in a nickel-based alloy. Journal of Materials Research 19, 1623–1629 (2004). https://doi.org/10.1557/JMR.2004.0227

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2004.0227