Abstract

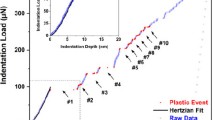

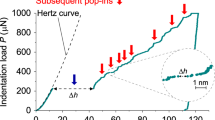

We propose a nucleation theory-based analysis for incipient plasticity during nanoindentation and predict the statistical distribution of rate-dependent pop-in events for many nominally identical indentations on the same surface. In the framework of stress-assisted, thermally activated defect nucleation, we quantitatively rationalize new nanoindentation measurements on 4H SiC and extract the activation volume of the nucleation events that mark the onset of plastic flow. We also illustrate how this statistical approach can differentiate between unique nucleation events for different indenter tip geometries.

Similar content being viewed by others

References

W.W. Gerberich, J.C. Nelson, E.T. Lilleodden, P. Anderson, and J.T. Wyrobek: Indentation Induced dislocation nucleation: The initial yield point. Acta Mater. 44, 3585 (1996).

D.E. Kramer, K.B. Yoder, and W.W. Gerberich: Surface constrained plasticity: Oxide Rupture and the yield point process. Philos. Mag. A81, 2033 (2001).

W.W. Gerberich, S.K. Venkataraman, H. Huang, S.E. Harvey, and D.L. Kohlstedt: The injection of plasticity by millinewton contacts. Acta Metall. Mater. 43, 1569 (1995).

J.S. Field, M.V. Swain, and R.D. Dukino: Determination of fracture toughness from the extra penetration produced by indentationinduced pop-in. J. Mater. Res. 18, 1412 (2003).

W.J. Wright, R. Saha, and W.D. Nix: Deformation mechanisms of the Zr40Ti14Ni10Cu12Be24 bulk metallic glass. Mater. Trans. JIM. 42, 642 (2001).

A.L. Greer, A. Castellero, S.V. Madge, I.T. Walker, and J.R. Wilde: Nanoindentation studies of shear banding in fully amorphous and partially devitrified metallic alloys. Mater. Sci. Eng. A (2004, in press).

C.A. Schuh and T.G. Nieh: A nanoindentation study of serrated flow in bulk metallic glasses. Acta Mater. 51, 87 (2003).

C.A. Schuh and T.G. Nieh: A survey of instrumented indentation studies on metallic glasses. J. Mater. Res. 19, 46 (2004).

N.Q. Chinh, G. Horváth, Z. Kovács, and J. Lendvai: Characterization of plastic instability steps occurring in depth-sensing indentation tests. Mater. Sci. Eng A 324, 219 (2002).

G. Berces, N.Q. Chinh, A. Juhasz, and J. Lendvai: Occurrence of plastic instabilities in dynamic microhardness testing. J. Mater. Res. 13, 1411 (1998).

S.G. Corcoran, R.J. Colton, E.T. Lilleodden, and W.W. Gerberich: Anomalous plastic deformation at surfaces: Nanoindentation of gold single crystals. Phys. Rev. B 55, R16057 (1997).

M. Pang, D.F. Bahr, and K.G. Lynn: Effects of Zn addition and thermal annealing on yield phenomena of CdTe and Cd0.96Zn0.04Te single crystals by nanoindentation. Appl. Phys. Lett. 82, 1200 (2003).

Y.L. Chiu and A.H.W. Ngan: A TEM investigation on indentation plastic zones in Ni3Al(Cr,B) single crystals. Acta Mater. 50, 2677 (2002).

A. Gouldstone, H-J. Koh, K-Y. Zeng, A.E. Giannakopoulos, and S. Suresh: Discrete and continuous deformation during nanoindentation of thin films. Acta Mater. 48, 2277 (2000).

S. Suresh, T.G. Nieh, and B.W. Choi: Nano-indentation of copper thin films on silicon substrates. Scripta Mater. 41, 951 (1999).

D. Lorenz, A. Zeckzer, U. Hilpert, P. Grau, H. Johansen, and H.S. Leipner: Pop-in effect as homogeneous nucleation of dislocations during nanoindentation. Phys. Rev. B 67, 172101 (2003).

C.L. Kelchner, S.J. Plimpton, and J.C. Hamilton: Dislocation nucleation and defect structure during surface indentation. Phys. Rev. B 58, 11085 (1998).

A. Gannepalli and S.K. Mallapragada: Atomistic studies of defect nucleation during nanoindentation of Au(001). Phys. Rev. B 66, 104103 (2002).

J. Knap and M. Ortiz: Effect of indenter-radius size on Au(001) nanoindentation. Phys. Rev. Lett. 90, 226102 (2003).

E.T. Lilleodden, J.A. Zimmerman, S.M. Foiles, and W.D. Nix: Atomistic simulations of elastic deformation and dislocation nucleation during nanoindentation. J. Mech. Phys. Solids 51, 901 (2003).

J. Li, K.J. Van-Vliet, T. Zhu, S. Yip, and S. Suresh: Atomistic mechanisms governing elastic limit and incipient plasticity in crystals. Nature 418, 307 (2002).

D.F. Bahr, D.E. Wilson, and D.A. Crowson: Energy considerations regarding yield points during indentation. J. Mater. Res. 14, 2269 (1999).

Y.L. Chiu and A.H.W. Ngan: Time-dependent characteristics of incipient plasticity in nanoindentation of a Ni3Al single crystal. Acta Mater. 50, 1599 (2002).

S.A. Syed-Asif and J.B. Pethica: Nanoindentation creep of singlecrystal tungsten and gallium arsenide. Philos. Mag. A76, 1105 (1997).

W. Wang, C.B. Jiang, and K. Lu: Deformation behavior of Ni3Al single crystals during nanoindentation. Acta Mater. 51, 6169 (2003).

T.A. Michalske and J.E. Houston: Dislocation nucleation at nanoscale contacts. Acta Mater. 46, 391 (1998).

B.J. Kooi, R.J. Poppen, N.J.M. Carvalho, J.T.M. DeHosson, and M.W. Barsoum: Ti3SiC2: A damage tolerant ceramic studied with nanoindentations and transmission electron microscopy. Acta Mater. 51, 2859 (2003).

K.S. Lee, J.Y. Park, W-J. Kim, M.Y. Lee, C.H. Jung, and G.W. Hong: Effect of soft substrate on the indentation damage in silicon carbide deposited on graphite. J. Mater. Sci. 35, 2769 (2000).

T.F. Page, W.C. Oliver, and C.J. McHargue: The deformation behavior of ceramic crystals subjected to very low load (nano)indentations. J. Mater. Res. 7, 450 (1992).

K. Pohlmann, B. Bhushan, and K-H.Z. Gahr: Effect of thermal oxidation on indentation and scratching of single-crystal silicon carbide on microscale. Wear 237, 116 (2000).

J. Woirgard, T. Cabioc’h, J.P. Riviere, and J.C. Dargenton: Nanoindentation characterization of SiC coatings prepared by dynamic ion mixing. Surf. Coat. Technol. 100, 128 (1998).

A.B. Mann, M. Balooch, J.H. Kinney, and T.P. Weihs: Radial variations in modulus and hardness in SCS-6 silicon carbide fibers. J. Am. Ceram. Soc. 82, 111 (1999).

K.L. Johnson, Contact Mechanics (Cambridge University Press, Cambridge, U.K., 1985).

A.B. Mann and J.B. Pethica: The effect of tip momentum on the contact stiffness and yielding during nanoindentation testing. Philos. Mag. A 79, 577 (1999).

A.B. Mann and J.B. Pethica: The role of atomic size asperities in the mechanical deformation of nanocontacts. Appl. Phys. Lett. 69, 907 (1996).

W.C. Oliver and G.M. Pharr: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564 (1992).

D.J. Green, An Introduction to the Mechanical Properties of Ceramics (Cambridge University Press, Cambridge, U.K., 1998).

D.F. Bahr, D.E. Kramer, and W.W. Gerberich: Non-linear deformation mechanisms during nanoindentation. Acta Mater. 46, 3605 (1998).

N.I. Tymiak, D.E. Kramer, D.F. Bahr, J.T. Wyrobek, and W.W. Gerberich: Plastic strain and strain gradients at very small indentation depths. Acta Mater. 49, 1021 (2001).

Y.I. Golovin, A.I. Tyurin, and B.Y. Farber: Time-dependent characteristics of materials and micromechanisms of plastic deformation on a submicron scale by a new pulse indentation technique. Philos. Mag. A82, 1857 (2002).

B.Y. Farber, V.I. Orlov, and A.H. Heuer: Energy dissipation during high-temperature displacement-sensitive indentation in cubic zirconia single crystal. Phys. Status Solidi A 166, 115 (1998).

Y.I. Golovin, A.I. Tyurin, and B.Y. Farber: Investigation of timedependent characteristics of materials and micromechanisms of plastic deformation on a submicron scale by a new pulse indentation technique. J. Mater. Sci. 37, 895 (2002).

B.Y. Farber, V.I. Orlov, V.I. Nykitenko, and A.H. Heuer: Mechanisms of energy dissipation during displacement-sensitive indentation in Ge single crystals at elevated temperatures. Philos. Mag. A 78, 671 (1998).

J.D. Kiely and J.E. Houston: Nanomechanical properties of Au (111), (001), and (110) surfaces. Phys. Rev. B 57, 12588 (1998).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Schuh, C.A., Lund, A.C. Application of nucleation theory to the rate dependence of incipient plasticity during nanoindentation. Journal of Materials Research 19, 2152–2158 (2004). https://doi.org/10.1557/JMR.2004.0276

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2004.0276