Abstract

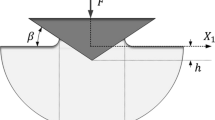

The curvature of the loading curve, the initial slope of the unloading curve, and the ratio of the residual depth to maximum indentation depth are three main quantitiesthat can be established from an indentation load-displacement curve. A relationship among these three quantities was analytically derived. This relationship is valid for elasto-plastic material with power law strain hardening and indented by conical indenters of any geometry. The validity of this relationship is numerically verified through large strain, large deformation finite element analyses. The existence of an intrinsic relationship among the three quantities implies that only two independent quantities can be obtained from the load-displacement curve of a single conical indenter. The reverse analysis of a single load-displacement curve will yield non-unique combinations of elasto-plastic material properties due to the availability of only two independent quantities to solve for the three unknown material properties.

Similar content being viewed by others

References

A.E. Giannakopoulos and S. Suresh: Determination of elastoplas-tic properties by instrumented sharp indentation. Scripta Mater. 40, 1191 (1999).

M. Dao, N. Chollacoop, K.J. Van Vliet, T.A. Venkatesh, and S. Suresh: Computational modelling of the forward and reverse problems in instrumented sharp indentation. Acta Mater. 49, 3899 (2001).

N. Chollacoop, M. Dao, and S. Suresh: Depth-sensing instrumented indentation with dual sharp indenters. Acta Mater. 51, 3713 (2003).

K. Zeng and C.H. Chiu: An analysis of load-penetration curves from instrumented indentation. Acta Mater. 49, 3539 (2001).

Y.T. Cheng and C.M. Cheng: Can stress-strain relationships be obtained from indentation curves using conical and pyramidal indenters? J. Mater. Res. 14, 3493 (1999).

T.W. Capehart and Y.T. Cheng: Determining constitutive models from conical indentation: Sensitivity analysis. J. Mater. Res. 18, 827 (2003).

K.K. Tho, S. Swaddiwudhipong, Z.S. Liu, and K. Zeng: Simulation of instrumented indentation and material characterization. (submitted for publication).

W.C. Oliver and G.M. Pharr: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564 (1992).

J.L. Loubet, J.M. Georges, O. Marchesini, and G. Meille: Vickers indentation curves of magnesium oxide (MgO). J. Tribol. 106, 43 (1984).

Y.T. Cheng, Z. Li, and C.M. Cheng: Scaling relationships for indentation measurements. Philos. Mag. A 82, 1821 (2002).

J.L. Bucaille, S. Stauss, E. Felder, and J. Michler: Determination of plastic properties of metals by instrumented indentation using different sharp indenters. Acta Mater. 51, 1663 (2003).

S. Kalpakjian and S.R. Schmid: Manufacturing Processes for Engineering Materials, (Prentice Hall, New Jersey, 2003), p. 33.

MatWeb: http://www.matweb.com, 2003, by Automation Creations, Inc.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Tho, K.K., Swaddiwudhipong, S., Liu, Z.S. et al. Uniqueness of reverse analysis from conical indentation tests. Journal of Materials Research 19, 2498–2502 (2004). https://doi.org/10.1557/JMR.2004.0306

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2004.0306