Abstract

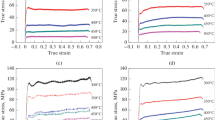

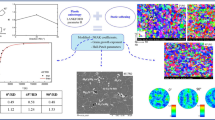

The indentation behavior of cold-rolled AA6061 Al alloy was investigated. Following the approach suggested by Tabor, indentation stress-indentation strain curves were constructed and analyzed. The indentation stress required to create the same indentation strain increases with an increase in the reduction of thickness, suggesting a strong effect of plastic deformation history on the deformation behavior of materials. Through the dislocation dynamics, the evolution of the dislocations underneath the indentation was correlated with the plastic deformation history and the indentation load. The plastic energy dissipated in indentation was then calculated and found to be proportional to the 3/2 power of the indentation load and the 3/4 power of the average dislocation density underneath the indentation. The ratio of the dissipated plastic energy to the total energy in the indentation was demonstrated to be a function of the deformation state in materials, independent of the indentation load.

Similar content being viewed by others

References

Y. Saito, H. Utsunomiya, N. Tsuji, and T. Sakai: Novel ultra-high straining process for bulk materials—Development of the accumulative roll-bonding (ARB) process. Acta Mater. 47, 579 (1999).

C.P. Heason and P.B. Prangnell: Grain refinement and texture evolution during the deformation of Al to ultra-high strains by accumulative roll bonding (ARB). Mater. Sci. Forum 396, 429 (2002).

B.Q. Han, and S. Yue: Processing of ultrafine ferrite steels. J. Mater. Process. Technol. 136, 100 (2003).

W.Q. Cao, Q. Liu, A. Godfrey, and N. Hansen: Microstructure and texture evolution during annealing of an aluminium ARB material. Mater. Sci. Forum 408, 721 (2002).

S.H. Lee, H. Utsunomiya, and T. Sakai: Microstructures and mechanical properties of ultra low carbon interstitial free steel severely deformed by a multi-stack accumulative roll bonding process. Mater. Trans. 45, 2177 (2004).

K.T. Park, H.J. Kwon, W.J. Kim, and Y.S. Kim: Microstructural characteristics and thermal stability of ultrafine grained 6061 Al alloy fabricated by accumulative roll bonding process. Mater. Sci. Eng. A 316, 145 (2001).

X. Huang, N. Tsuji, N. Hansen, and Y. Minamino: Microstructural evolution during accumulative roll-bonding of commercial purity aluminum. Mater. Sci. Eng. A 340, 265 (2003).

Y.B. Lee, D.H. Shin, K.T. Park, and W.J. Nam: Effect of annealing temperature on microstructures and mechanical properties of a 5083 Al alloy deformed at cryogenic temperature. Script. Mater. 51, 355 (2004).

G.U. Oppel: Biaxial elasto-plastic analysis of load and residual stresses (Load and residual stress effects on metal hardness). Exp. Mech. 21, 135 (1964).

A.W. Eberhardt, R. Pandey, J.M. Williams, J.J. Weimer, D. Ila, and R.L. Zimmerman: The roles of residual stress and surface topography on hardness of Ti implanted Ti–6Al–4V. Mater. Sci. Eng. A 229, 147 (1997).

W.R. Lafontaine, C.A. Paszkiet, M.A. Korhonen Ma, and C.Y. Li: Residual-stress measurements of thin aluminum metallizations by continuous indentation and x-ray stress measurement techniques. J. Mater. Res. 6, 2084 (1991).

T.R. Simes, S.G. Mellor, and D.A. Hills: A note on the influence of residual-stress on measured hardness. J. Strain Analysis 19, 135 (1984).

J.G. Swadener, B. Taljat, and G.M. Pharr: Measurement of residual stress by load and depth-sensing indentation with spherical indenters. J. Mater. Res. 16, 2091 (2001).

F.Q. Yang, L.L. Peng, and K. Okazaki: Micro-indentation of aluminum processed by equal channel angular extrusion. J. Mater. Res. 19, 1243 (2004).

F.Q. Yang, L.L. Peng, and K. Okazaki: Microindentation of aluminum. Metall. Mater. Trans. A 35, 3323 (2004).

J.L. Hay, W.C. Oliver, A. Bolshakov, and G.M. Pharr: Using the ratio of loading slope and elastic stiffness to predict pile-up and constraint factor during indentation, in Fundamentals of Nanoindentation and Nanotribology, edited by N.R. Moody, W.W. Gerberich, N. Burnham, and S.P. Baker (Mater. Res. Soc. Symp. Proc. 522, Warrendale, PA, 1998), p. 101.

G.E. Dieter: Mechanical Metallurgy, 2nd ed. (McGraw-Hill, Inc., New York, NY, 1976)

J.S. Field and M.V. Swain: A simple predictive model for spherical indentation. J. Mater. Res. 8, 297 (1993).

D. Tabor: Hardness of Metals (Clarendon Press, Oxford, U.K., 1951).

F.Q. Yang, L.L. Peng, and K. Okazaki: Localized deformation of equal channel angular extruded aluminum. Mater. Sci. Forum 475–479, 425 (2005).

Y. Bergström: A dislocation model for the strain-ageing behaviour of steel. Mater. Sci. Eng. 9, 101 (1972).

T. Hasegawa, Y. Sakurai, and K. Okazaki: Grain size effect on thermal recovery during high temperature deformation of aluminum tested at constant true strain rates. Mater. Sci. Eng. A 346, 34 (2003).

Properties and Selection: Nonferrous Alloys and Special-Purpose Materials, Metals Handbook, Vol. 2, 10th ed. (ASM International, Materials Park, OH, 1991), p. 103.

Y.T. Cheng and C.M. Cheng: Scaling, dimensional analysis, and indentation measurements. Mater. Sci. Eng. R44, 91 (2004).

R. Hill: The Mathematical Theory of Plasticity (Clarendon Press, Oxford, U.K., 1950).

M. Dao, N. Chollacoop, K.J. Van Vliet, T.A. Venkatesh, and S. Suresh: Computational modeling of the forward and reverse problems in instrumented sharp indentation. Acta Mater. 49, 3899 (2001).

Y.T. Cheng, Z. Li, and C.M. Cheng: Scaling relationships for indentation measurements. Philos. Mag. A82, 1821 (2002).

M.K. Shorshorov, S.I. Bulychev, and V.P. Alekin: Work of plastic and elastic deformation during indenter indentation. Sov. Phys. Dokl. 26, 769 (1981).

J. Malzender: Energy dissipated during spherical indentation. J. Mater. Res. 19, 1605 (2004).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, F., Du, W. & Okazaki, K. Effect of cold rolling on the indentation deformation of AA6061 aluminum alloy. Journal of Materials Research 20, 1172–1179 (2005). https://doi.org/10.1557/JMR.2005.0178

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2005.0178