Abstract

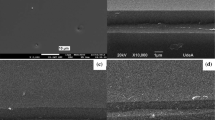

Chromium oxide coatings were deposited on low-carbon steel by radiofrequency reactive magnetron sputtering at different oxygen flux values. X-ray diffraction, x-ray photoelectron spectroscopy, and high-resolution transmission electron microscopy were used to investigate the microstructure of chromium oxide coatings. Varying oxygen flux changed the coating microstructure; as with increasing oxygen flux the chromium oxide coating undergoes amorphous-to-crystalline transformation. The coating developed strong (300) texture at higher oxygen flux. Hardness, elastic modulus, wear resistance, and adhesion were investigated by nanoindentation and pin-on-disk tests. With changes in the coating microstructure as a function of increased oxygen flux, hardness, elastic modulus, and wear resistance were improved, but its adhesion was weakened.

Similar content being viewed by others

References

F.D. Lai, C.Y. Huang, C.M. Chang, L.A. Wang, and W.C. Cheng: Ultra-thin Cr2O3 well-crystallized films for high transmittance APSM in ArF line. Microelectron. Eng. 67/68, 17 (2003).

E. Sourty, J.L. Sullivan, and M.D. Bijker: Chromium oxide coatings applied to magnetic tape heads for improved wear resistance. Tribol. Int. 36, 389 (2003).

P. Hones, M. Diserens, and F. Levy: Characterization of sputterdeposited chromium oxide thin films. Surf. Coat. Technol. 120/121, 277 (1999).

U. Rothhaar and H. Oechsner: Temperature induced dissolution of Cr2O3 into polycrystalline tantalum. Thin Solid Films 302, 266 (1997).

B. Bhushan, M.A.S.G. Theumissen, and X. Li: Tribological studies of chromium oxide films for magnetic recording applications. Thin Solid Films 311, 67 (1997).

P. Yashar, J. Rechner, M.S. Wong, W.D. Sproul, and S.A. Barnett: High-rate reactive sputtering of yttria-stabilized zirconia using pulsed d.c. power. Surf. Coat. Technol. 94/95, 333 (1997).

J.D. Olivas, C. Mireles, E. Acosta, and E.V. Barrera: Surface characterization of plasma spray metal deposition procedures using x-ray photoelectron spectroscopy. Thin Solid Films 299, 143 (1997).

I. Ozdemir, C. Tekmen, S.C. Okumus, and E. Celik: Thermal behaviour of plasma-sprayed Mo coating on cast-iron substrate. Surf. Coat. Technol. 174/175, 1064 (2003).

A. Forn, J.A. Picas, and M.J. Simon: Mechanical and tribological properties of Al–Si–Mo plasma-sprayed coatings. J. Mater. Process. Technol. 143/144, 52 (2003).

S.A. Kao, F.M. Doerner, and J.V. Novotny: Processing effects on the tribological characteristics of reactively sputtered chromium oxide (Cr2O3) overcoat films. J. Appl. Phys. 66, 5315 (1989).

G. Contoux, F. Cosset, A. Celerier, and J. Machet: Deposition process study of chromium oxide thin films obtained by d.c. magnetron sputtering. Thin Solid Films 292, 75 (1997).

B. Bhushan: Development of r.f. sputtered chromium oxide coating for wear application. Thin Solid Films 64, 231 (1979).

E. Andrade, M. Flores, S. Muhl, N.P. Barradas, G. Murillo, E.P. Zavala, and M.F. Rocha: Ion beam analysis of TiN/Ti multilayers deposited by magnetron sputtering. Nucl. Instrum. Methods Phys. Res., Sect. B 219/220, 763 (2004).

J. Creus, H. Mazille, and H. Idrissi: Porosity evaluation of protective coatings onto steel, through electrochemical techniques. Surf. Coat. Technol. 130, 224 (2000).

C. Liu, A. Leyland, Q. Bi, and A. Matthews: Corrosion resistance of multi-layered plasma-assisted physical vapour deposition TiN and CrN coatings. Surf. Coat. Technol. 141, 164 (2001).

M. Fenker, M. Balzer, H.A. Jehn, H. Kappl, J.J. Lee, K-H. Lee, and H-S. Lee: Improvement of the corrosion resistance of hard wear resistant coatings by intermediate plasma etching or multilayered structure. Surf. Coat. Technol. 150, 101 (2002).

K.D. Bouzakis, S. Hadjiyiannis, G. Skordaris, I. Mirisidis, N. Michailidis, and G. Erkens: Wear development on cemented carbide inserts, coated with variable film thickness in the cutting wedge region. Surf. Coat. Technol. 188/189, 636 (2004).

A.D. Sarkar: Friction and Wear (Academic Press, New York, 1940). p. 3.

C.D. Wagner, W.M. Riggs, L.E. Davis, and J.F. Moulder: Handbook of X-ray Photoelectron Spectroscopy, (Perkin-Elmer, Pittsburgh, PA, 1979). p. 73.

PDF Card No. 06–0694, PCPDFWIN, Version 2.02, JCPDSICDD, 1999.

M. Murakami and R. Vook: Strain-relaxation mechanisms of thin deposited films. Crit. Rev. Solid State Mater. Sci. 11, 317 (1983).

K.L. Johnson: Contact Mechanics (Cambridge Press, Cambridge, UK, 1985). p. 153.

X. Pang, K. Gao, H. Yang, L. Qiao, Y. Wang, and A.A. Volinsky: Interfacial microstructure of chromium oxide coatings. Adv. Eng. Mater. 9, 594 (2007).

A. Leyland and A. Matthews: Thick Ti/TiN multilayered coatings for abrasive and erosive wear resistance. Surf. Coat. Technol. 70, 19 (1994).

G.S. Kim, S.Y. Lee, J.H. Hahn, B.Y. Lee, J.G. Han, J.H. Lee, and S.Y. Lee: Effects of the thickness of Ti buffer layer on the mechanical properties of TiN coatings. Surf. Coat. Technol. 171, 83 (2003).

X. Pang, K. Gao, and A.A. Volinsky: Annealing effects on microstructure and mechanical properties of chromium oxide coatings. Thin Solid Films doi: 10.1016/j.tsf.2007.08.083 (2007).

H. Choi, S. Choi, O. Anderson, and K. Bange: Influence of film density on residual stress and resistivity for Cu thin films deposited by bias sputtering. Thin Solid Films 358, 202 (1999).

G. Mohan Rao and S. Mohan: Studies on glow-discharge characteristics during dc reactive magnetron sputtering. J. Appl. Phys. 69, 6652 (1991).

A.A. Volinsky, N.R. Moody, and W.W. Gerberich: Interfacial toughness measurements for thin films on substrates. Acta Mater. 50, 441 (2002).

A.A. Volinsky, J.B. Vella, and W.W. Gerberich: Fracture toughness, adhesion and mechanical properties of low-K dielectric thin films measured by nanoindentation. Thin Solid Films 429, 201 (2002).

X.D. Li, D.F. Diao, and B. Bhushan: Fracture mechanisms of amorphous carbon films in nanoindentation. Acta Mater. 45, 4453 (1997).

B. Bhushan and X.D. Li: Nanomechanical characterization of solid surfaces and thin films. Int. Mater. Rev. 48, 125 (2003).

Acknowledgments

This work was supported by the National Natural Science Foundation of China (No. 50471091). Xiaolu Pang would like to acknowledge the support from the State Scholarship Fund of China (No. 20063037). Alex Volinsky would like to acknowledge the support from the National Science Foundation (CMMI-0600266, CMMI-0631526, and CMMI-0600231). We acknowledge help from Huisheng Yang, Yanbin Wang, and Lijie Qiao with sample preparation and mechanical testing.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pang, X., Gao, K. & Volinsky, A.A. Microstructure and mechanical properties of chromium oxide coatings. Journal of Materials Research 22, 3531–3537 (2007). https://doi.org/10.1557/JMR.2007.0445

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2007.0445