Abstract

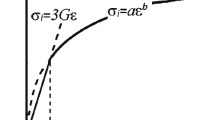

With thin solid film usage expanding in numerous technologies, reliable measurements of material properties such as yield strength become important. However, for thin solid films the measurement of yield strength is not readily available, and an alternative method to obtain this property is to measure hardness and convert it to yield strength. Tabor suggested dividing hardness by ∼3 to obtain yield strength, which has been used extensively, despite its shortcomings. Since the pioneering work of Tabor, researchers have performed numerical and experimental studies to investigate the relationships between hardness, yield strength, and elastic modulus, using the indentation technique. In this study, finite element analysis was performed to simulate the nanoscratch technique. Specifically, the nanoscratch finite element analysis was used to validate a previously developed analytical scratch hardness model. A full-factorial design-of-experiments was performed to determine the significant variables for the ratio of calculated scratch hardness to yield strength and a simple analytical prediction model for the ratio of hardness to yield strength was proposed.

Similar content being viewed by others

References

W.C. Oliver, G.M. Pharr: Improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564 1992

N. Yu, W.A. Bonin, A.A. Polycarpou: High-resolution capacitive load-displacement transducer and its application in nanoindentation and adhesion force measurements. Rev. Sci. Instrum. 76, 045109 2005

K.M. Lee, C-D. Yeo, A.A. Polycarpou: Nanomechanical property and nanowear measurements for sub-10 nm thick films in magnetic storage. Exp. Mech. 47, 107 2007

X. Li, B. Bhushan: Measurement of fracture toughness of ultra-thin amorphous carbon films. Thin Solid Films 315, 214 1998

J. Goddard, H. Wilman: A theory of friction and wear during the abrasion of metals. Wear 5, 114 1962

N. Tayebi, T.F. Conry, A.A. Polycarpou: Determination of hardness from nanoscratch experiments: Corrections for interfacial shear stress and elastic recovery. J. Mater. Res. 18, 2150 2003

H. Bückle: The Science of Hardness Testing and Its Research Applications American Society for Metals Metals Park, OH 1973

N. Tayebi, A.A. Polycarpou, T.F. Conry: Effects of the substrate on the determination of hardness of thin films by the nanoscratch and nanoindentation techniques. J. Mater. Res. 19, 1791 2004

M.A. Haque, M.T.A. Saif: In-situ tensile testing of nano-scale specimens in SEM and TEM. Exp. Mech. 42, 123 2002

S. Cho, I. Chasiotis, T.A. Friedmann, J.P. Sullivan: Young’s modulus, Poisson’s ratio and failure properties of tetrahedral amorphous diamond-like carbon for MEMS devices. J. Micromech. Microeng. 15, 728 2005

D. Tabor: Hardness of Metals Clarendon Press Oxford 1951

Y.T. Cheng, C.M. Cheng: Scaling approach to conical indentation in elastic-plastic solids with work hardening. J. Appl. Phys. 84, 1284 1998

M. Mata, M. Anglada, J. Alcala: Contact deformation regimes around sharp indentation and the concept of the characteristic strain. J. Mater. Res. 17, 964 2002

L.J. Vandeperre, F. Giuliani, W.J. Clegg: Effect of elastic surface deformation on the relation between hardness and yield strength. J. Mater. Res. 19, 3704 2004

N. Yu, A.A. Polycarpou, T.F. Conry: Tip-radius effect in finite element modeling of sub-50 nm shallow nanoindentation. Thin Solid Films 450, 295 2004

J.L. Bucaille, E. Felder, G. Hochstetter: Mechanical analysis of the scratch test on elastic and perfectly plastic materials with the three-dimensional finite element modeling. Wear 249, 422 2001

G. Subhash, W. Zhang: Investigation of the overall friction coefficient in single-pass scratch test. Wear 252, 123 2002

E.R. Kral, K. Komvopoulos, D.B. Bogy: Hardness of thin-film media: Scratch experiments and finite element simulations. J. Tribol.—Trans. ASME 118, 1 1996

J. Boussinesq: Application of Potentials to the Study of Equilibrium and Motion of Elastic Bodies. Gauthier-Villars Paris, France 1885

N. Tayebi, T.F. Conry, A.A. Polycarpou: Reconciliation of nanoscratch hardness with nanoindentation hardness including the effects of interface shear stress. J. Mater. Res. 19, 3316 2004

B. Bhushan: Chemical, mechanical and tribological characterization of ultra-thin and hard amorphous carbon coatings as thin as 3.5 nm: Recent developments. Diamond Relat. Mater. 8, 1985 1999

R.E. DeVor, T. Chang, J.W. Sutherland: Statistical Quality Design and Control: Contemporary Concepts and Methods. 2nd ed. Prentice Hall, NJ 2006

B. Bhushan, X.D. Li: Micromechanical and tribological characterization of doped single-crystal silicon and polysilicon films for microelectromechanical systems devices. J. Mater. Res. 12, 54 1997

X.D. Li, B. Bhushan, K. Takashima, C.W. Baek, Y.K. Kim: Mechanical characterization of micro/nanoscale structures for MEMS/NEMS applications using nanoindentation techniques. Ultramicroscopy 97, 481 2003

Acknowledgments

This research was supported by grants from the Information Storage Industry Consortium (INSIC) Extremely High Density Recording (EHDR) Program and the National Science Foundation under grant number CAREER CMS-0239232. Also, this work was supported by the National Center for Supercomputing Applications under TG-MSS05005N and used the IBM P690 (Copper) computing resources (where all the FEA simulations using ABAQUS were performed).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lee, K.M., Yeo, CD. & Polycarpou polycarp@uiuc.edu, A.A. Relationship between scratch hardness and yield strength of elastic perfectly plastic materials using finite element analysis. Journal of Materials Research 23, 2229–2237 (2008). https://doi.org/10.1557/JMR.2008.0279

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2008.0279