Abstract

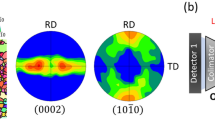

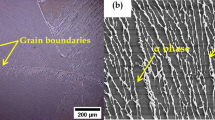

Texture evolution of a commercial-purity titanium (CP-Ti) during cold rolling was studied by means of x-ray diffraction (XRD) and electron back-scattered diffraction (EBSD). Twinning was identified to significantly contribute to deformation up to reductions of about 50%. Based on initial texture of the material investigated and twinning modes available in hexagonal close-packed (HCP) structures, the measured texture evolution can be interpreted in terms of (i) compressive twinning ({11¯22}〈11¯2¯3〉) within the two dominant initial texture components B ({0001}〈10¯10〉±40°TD) and E ({0001}〈11¯20〉±40°TD) and (ii) followed by tensile twinning ({10¯12}〈10¯1¯1〉) in the then-favorably reoriented twinned part. Reduction of grain size at high deformation inhibits further twinning and results in a stable texture evolution driven exclusively by dislocation slip. During cold rolling, the crystals of the initial texture component B first rotate to orientation M ({01¯10}〈2¯1¯12〉) by compressive twinning (primary), and then orientation M rotates to orientation D ({0001}〈11¯20〉) by tensile twinning (secondary). Meanwhile, the crystals of the initial component E first rotate to the orientation M′ ({14¯53}〈6¯5¯13〉) by compressive twinning (primary), and then orientation M′ rotates to the orientation A ({0001}〈10¯10〉) by tensile twinning (secondary). At higher deformation level, twinning was significantly depressed by strongly refined grain size, which resulted in the elimination of the transient texture components caused by slip. These results are useful for the prediction and control of the texture in titanium.

Similar content being viewed by others

References

H.J. Bunge: The general description on texture. Z. Metallkd. 56, 872 1965

S.V. Divinski: Effect of phase transformation on texture formation in Ti-base alloys. Mater. Sci. Eng., A 243, 201 1998

N. Gey, M. Humbert: Characterization of the variant selection occurring during the α → β → α phase transformations of a cold rolled titanium sheet. Acta Mater. 50, 277 2002

P. Klimanek, A. Potzsch: Microstructure evolution under compressive plastic deformation of magnesium at different temperatures and strain rates. Mater. Sci. Eng., A 324, 145 2002

T. Mukai, M. Yamanoi, H. Watanabe, K. Higashi: Ductility enhancement in AZ31 magnesium alloy by controlling its grain structure. Scr. Mater. 45, 89 2001

F. Larson, A. Zarkades: Properties of Textured Titanium Alloys Battelle—Columbus Laboratories, Ohio Metals and Ceramics Information Center, Columbus, OH, 1974

H. Inagaki: Development of cold-rolling textures in pure Ti. Z. Metallkd. 82, 779 1991

H. Inagaki: Texture and mechanical anisotropy in cold-rolled and annealed pure Ti sheets. Z. Metallkd. 83, 40 1992

D.N. Williams, D.S. Eppelsheimer: The cold rolled texture of titanium. Trans. AIME 197, 1378 1953

P. Dervin, J.P. Mardon, M. Pernot, R. Penelle, P. Lacombe: Application of 3-dimensional representation of textures to study of evolution of titanium recrystallization and rolling textures. J. Less-Common Met. 55, 25 1977

A.K. Singh, R.A. Schwarzer: Texture and anisotropy of mechanical properties in titanium and its alloys. Z. Metallkd. 91(9), 702 2000

P.R. Morris, A.J. Heckler: Crystallite orientation analysis for rolled hexagonal materials. Trans. AIME 245, 1877 1969

H. Moustahfid, M. Humbert, M.J. Philippe: Modeling of the texture transformation in a Ti-64 sheet after hot compression. Acta Mater. 45, 3785 1997

J.A. Elias, A.J. Heckler: Complete pole figure determination by composite sampling techniques. Trans. Met. Soc. AIME 239, 1237 1967

H.P. Lee, C. Esling, H.J. Bunge: Development of the rolling texture in titanium. Textures Microstruct. 7, 317 1988

D.R. Thornburg, H.R. Piehle: Cold-rolling texture development in titanium and titanium-aluminum alloys in Titanium Science and Technology Proc. of The Metallurgical Society of AIME 2 edited by R.I. Jaffee and H.M. Burte Plenum Press New York 1973 1187

E.A. Calnan, J.B. Clews: The development of deformation textures in metals. Part 3. Hexagonal structures. Philos. Mag. 42, 919 1951

M.J. Philippe, M. Serghat, P. Vanhoutte, C. Esling: Modeling of texture evolution for materials of hexagonal symmetry. Part 2. Application to zirconium and titanium alpha-alloys or near-alpha-alloys. Acta Metall. Mater. 43, 1619 1995

X.P. Wu, S.R. Kalidindi, C. Necker, A.A. Salem: Prediction of crystallographic texture evolution and anisotropic stress–strain curves during large plastic strains in high purity alpha-titanium using a Taylor-type crystal plasticity model. Acta Mater. 55, 423 2007

Y.N. Wang, J.C. Huang: Texture analysis in hexagonal materials. Mater. Chem. Phys. 81, 11 2003

P.G. Partridge: The crystallography and deformation modes of hexagonal close-packed metals. Met. Rev. 12(118), 169 1967

M.J. Phillipe: Texture formation in hexagonal materials. Mater. Sci. Forum 157–162,, 1337 1994

J.J. Fundenberger, M.J. Phillipe, F. Wagner, C. Esling: Modelling and prediction of mechanical properties for materials with hexagonal symmetry (zinc, titanium and zirconium alloys). Acta Mater. 45, 4041 1997

S.R. Agnew, M.H. Yoo, C.N. Tome: Application of texture simulation to understanding mechanical behavior of Mg and solid-solution alloys containing Li or Y. Acta Mater. 49, 4277 2001

V. Randle: A methodology for grain boundary plane assessment by single-section trace analysis. Scr. Mater. 44, 2789 2001

Y. Hu, V. Randle: An electron backscatter diffraction analysis of misorientation distributions in titanium alloys. Scr. Mater. 56, 1051 2007

Y.B. Chun, S.H. Yu, S.L. Semiatin, S.K. Hwang: Effect of deformation twinning on microstructure and texture evolution during cold rolling of CP-titanium. Mater. Sci. Eng., A 398, 209 2005

Y. Takayama, T. Miura, H. Kato, H. Watanabe: Microstructural and textural evolution by continuous cyclic bending and annealing in a high purity titanium. Mater. Trans. 45(9), 2826 2004

H.J. Bunge: Texture Analysis in Materials Science Butterworth London 1982

M.H. Yoo: Slip, twinning, and fracture in hexagonal close-packed metals. Metall. Mater. Trans. A 12, 409 1981

S.Y. Mironov, M.M. Myshiyaev: Evolution of dislocation boundaries during cold deformation of microcrystalline titanium. Phys. Solid State 49(5), 858 2007

S.I. Wright, R.J. Larsen: Extracting twins from orientation imaging microscopy scan data. J. Microsc. (Oxford) 205, 245 2002

N. Gey, M. Humbert, M.J. Philippe, Y. Combres: Modeling the transformation texture of Ti-64 sheets after rolling in the beta-field. Mater. Sci. Eng., A 230, 68 1997

H.J. Bunge, W.T. Roberts: Orientation distribution, elastic and plastic anisotropy in stabilized steel sheet. J. Appl. Crystallogr. 2, 116 1969

L. Jiang, J.J. Jonas, R.K. Mishra, A.A. Luo, A.K. Sachdev, S. Godet: Twinning and texture development in two Mg alloys subjected to loading along three different strain paths. Acta Mater. 55(11), 3899 2007

M. Battaini, E.V. Pereloma, C.H.J. Davies: Orientation effect on mechanical properties of commercially pure titanium at room temperature. Metall. Mater. Trans. A 38(2), 276 2007

M.J. Philippe, C. Esling, B. Hocheid: Role of twinning in texture development and in plastic-deformation of hexagonal materials. Textures Microstruct. 7, 265 1988

A. Salinas-Rodriguez: Grain size effects on the texture evolution of α-Zr. Acta Metall. Mater. 43, 485 1995

J.W. Christian, S. Mahajan: Deformation twinning. Prog. Mater. Sci. 39, 1 1995

D.R. Thornburg, H.R. Piehler: Analysis of constrained deformation by slip and twinning in hexagonal close packed metals and alloys. Metall. Trans. A 6, 1511 1975

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhong, Y., Yin, F. & Nagai, K. Role of deformation twin on texture evolution in cold-rolled commercial-purity Ti. Journal of Materials Research 23, 2954–2966 (2008). https://doi.org/10.1557/JMR.2008.0354

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2008.0354