Abstract

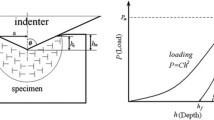

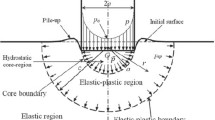

In our previous study, we modeled the indentation performed on an elastic–plastic solid with a rigid conical indenter by using finite element analysis, and established a relationship between a nominal hardness/reduced Young’s modulus (Hn/Er) and unloading work/total indentation work (We/Wt). The elasticity of the indenter was absorbed in Er ≡ 1/[(1 - v2)/E + (1 - vi2)/Ei], where Ei and vi are the Young’s modulus and Poisson’s ratio of the indenter, and E and v are those of the indented material. However, recalculation by directly introducing the elasticity of the indenter show that the use of Er alone cannot accurately reflect the combined elastic effect of the indenter and indented material, but the ratio η = [E/(1 - v2)]/[Ei/(1 - vi2)] would influence the Hn/Er–We/Wt relationship. Thereby, we replaced Er with a combined Young’s modulus Ec = 1/[(1 - v2)/E + 1.32(1 - vi2)/Ei] = Er/[1 + 0.32η/(1 + v)], and found that the approximate Hn/Ec–We/Wt relationship is almost independent of selected η values over 0–0.3834, which can be used to give good estimates of E as verified by experimental results.

Similar content being viewed by others

References

J.B. Pethica, R. Hutchings, W.C. Oliver Hardness measurement at penetration depth as small as 20 nm. Philos. Mag. A 48, 593 (1983)

J.L. Loubet, J.M. Georges, O. Marchesini, G. Meille Vickers indentation curves of magnesium oxide (MgO). J. Tribol. 106, 43 (1984)

D. Newey, M.A. Wilkens, H.M. Pollock An ultra-low-load penetration hardness tester. J. Phys. E: Sci. Instrum. 15, 119 (1982)

W.C. Oliver, G.M. Pharr An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564 (1992)

G.M. Pharr, W.C. Oliver, F.R. Brotzen On the generality of the relationship among contact stiffness, contact area, and elastic modulus during indentation. J. Mater. Res. 7, 613 (1992)

W.C. Oliver, G.M. Pharr Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 19, 3 (2004)

Y.-T. Cheng, C.-M. Cheng Relationships between hardness, elastic modulus, and the work of indentation. Appl. Phys. Lett. 73, 614 (1998)

Y.-T. Cheng, C.M. Cheng Scaling, dimension analysis, and indentation measurements. Mater. Sci. Eng., R 44, 91 (2004)

D. Ma, C.W. Ong, T. Zhang An improved energy method for determining Young’s modulus by instrumented indentation using a Berkovich tip. J. Mater. Res. 23, 2106 (2008)

D. Ma, C.W. Ong, T. Zhang An instrumented indentation method for Young’s modulus measurement with accuracy estimation. Exp. Mech. 49, 719 (2009)

M. Dao, N. Chollacoop, Van K.J. Vliet, T.A. Venkatesh, S. Suresh Computational modeling of the forward and reverse problems in instrumented sharp indentation. Acta Mater. 49, 3899 (2001)

M. Lichinchi, C. Lenardi, J. Haupt, R. Vitali Simulation of Berkovich nanoindentation experiments on thin films using finite element method. Thin Solid Films 312, 240 (1998)

Fischer-A.C. Cripps Use of combined elastic modulus in depth-sensing indentation with a conical indenter. J. Mater. Res. 18, 1043 (2003)

ABAQUS version 6.2 (Hibbitt, Karlsson & Sorensen, Inc, Pawtucket, RI 2001)

H. Lan, T.A. Venkatesh Determination of the elastic and plastic properties of materials through instrumented indentation with reduced sensitivity. Acta Mater. 55, 2025 (2007)

L. Liu, N. Ogasawara, N. Chiba, X. Chen Can indentation technique measure unique elastoplastic properties? J. Mater. Res. 24, 784 (2009)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ma, D., Ong, C.W. Further analysis of energy-based indentation relationship among Young’s modulus, nominal hardness, and indentation work. Journal of Materials Research 25, 1131–1136 (2010). https://doi.org/10.1557/JMR.2010.0137

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2010.0137