Abstract

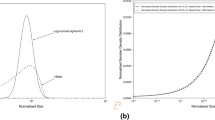

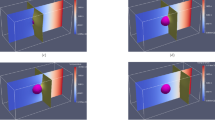

A model has been developed which allows for the graphical representation of undercooling and nucleation site density in G-V space (i.e. temperature gradient G versus growth rate V). This model is used to explain a unique grain structure in weldments where equiaxed grains may be found both at the fusion boundary and along the center of the weld metal. Details of this model will be given and discussed in relation to grain refinement predictions in G- V space.

Similar content being viewed by others

References

W.F. Savage, and A.H. Aronson, Weld. J., 45, 85s (1996).

M. Kato, F. Matsuda, and T. Senda, Trans. Jpn. Weld. Soc., 3, 69 (1972).

Y. Arata, F. Matsuda, and A. Matsui, Trans. JWRI, 3, 89 (1974).

T. Ganaha, B.P. Pearce, and H.W. Kerr, Met. Trans., 11A, 1351 (1980).

S. Kou, and Y. Le, Met. Trans., 19A, 1075 (1988).

C.E. Cross, L.W. Loechel, and G.F. Braun, in Proc. 6th Int. AI-Li Conf. (Deutsche Gessellschaft fur Materialkunde, Oberusel, Germany, 1991), p. 1165.

S.R. Shah, J.E. Wittig, and G.T. Hahn, in Int. Trends in Welding Sci. and lech. (ASM Int., Materials, Park, Ohio, 1992), p. 281.

Y. He, D. Gao, L. Wu, and L. Ming, in Proc. 3rd lnt. Conf Al Alloys (SINTEF, Trondhiem, Norway, 1992), p. 385.

C.E. Cross, and W.T. Tack, in ASM Handbook-Vol. 6 (ASM Int., Materials, Park, Ohio, 1993), p. 549.

A. Gutierrez, J.C. Lippold, and W. Lin, Mat. Sci. Forum, 217–222, 1691 (1996).

M.F. Lee, J.C. Huan, and N.J. Ho, J. Mat. Sci., 31, 1455 (1996).

K. K. Soni, R. Levi-Setti, S. Shah, and S. Getz, Adv. Mat. Process., 149, 35 (1996).

A. Gutierrez, and J.C. Lippold, Weld. J., 77, 123s (1998).

G.M. Reddy, A.A. Gokhale, K.S. Prasad, and K Prasad Rao, Sci. Tech. Weld. Join., 3, 208 (1998).

W.F. Savage, C.D. Lundin, and A.H. Aronson, Weld. J., 44, 175s (1965).

W.A. Tiller, K.A. Jackson, J.W. Rutter, and B. Chalmers, Acta Met., 1, 428 (1953).

J.D. Hunt, Mat. Sci. Eng., 65, 75 (1984).

C.E. Cross, Ø. Grong, and M. Mousavi, Scripta Mat., 40, 1139 (1999).

M.H. Burden, and J.D. Hunt, J. Crystal Growth, 22, 99 (1974).

W. Kurz, and D.J. Fisher, Fundamentals of Solidification (Trans. Tech. Pub., Switzerland, 1986).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Grong, Ø., Cross, C.E. A Model for Predicting Weld Metal Grain Refinement in G-V Space. MRS Online Proceedings Library 578, 431–438 (1999). https://doi.org/10.1557/PROC-578-431

Published:

Issue Date:

DOI: https://doi.org/10.1557/PROC-578-431