Abstract

It is well known that the mechanical properties of thin films depend critically on film thickness However, the contributions from film thickness and grain size are difficult to separate, because they typically scale with each other. In one study by Venkatraman and Bravman, Al films, which were thinned using anodic oxidation to reduce film thickness without changing grain size, showed a clear increase in yield stress with decreasing film thickness.

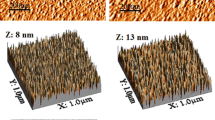

We have performed a similar study on both electroplated and sputtered Cu films by using chemical-mechanical polishing (CMP) to reduce the film thickness without changing the grain size. Stress-temperature curves were measured for both the electroplated and sputtered Cu films with thicknesses between 0.1 and 1.8 microns using a laser scanning wafer curvature technique. The yield stress at room temperature was found to increase with decreasing film thickness for both sets of samples. The sputtered films, however, showed higher yield stresses in comparison to the electroplated films. Most of these differences can be attributed to the different microstructures of the films, which were determined by focused ion beam (FIB) microscopy and x-ray diffraction.

Similar content being viewed by others

References

A. Gangulee, J. Appl. Phys. 43(3), 867–873 (1972).

C. Lingk and M. E. Gross, J. of Appl. Phys. 84(10), 5547–5553 (1998).

C. Lingk, M. E. Gross, and W. L. Brown, Appl. Phys. Lett. 74(5), 682–684 (1999).

M. Murakami, Thin Solid Films 59, 105 (1979).

R. Venkatraman and J. C. Bravman, J. Mater. Res. 7, 2040 (1992).

R. P. Vinci, E. M. Zielinski, and J. C. Bravman, Thin Solid Films 262, 142 (1995).

R.-M. Keller, S Bader, R. P. Vinci, and E. Arzt, Mat. Res. Soc. Symp. Proc. 356, 453–458 (1995).

R.-M. Keller, S. P. Baker, and E. Arzt, J. Mater. Res. 13(5), 1307–1317 (1998).

L. B. Freund, J. of Appl. Mech. 54, 553 (1987).

W. D. Nix, Metall. Trans. A 20, 2217 (1989).

C. V. Thompson, J. Mater. Res. 8(2), 237–238 (1993).

J. E. Sanchez, Jr. and E. Arzt, Scripta Metall. et Mater. 27, 285–290 (1992).

C. A. Volkert, J. Appl. Phys. 70(7), 3521–3527 (1991).

C. V. Thompson and R. Carel, Mat. Sci. and Eng. B 32, 221 (1995).

H. J. Frost, C. V. Thompson, and D. T. Walton, Acta Metall. et Mater. 38, 1455 (1990).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Spolenak, R., Volkert, C.A., Takahashi, K. et al. Mechanical Properties of Electroplated Copper Thin Films. MRS Online Proceedings Library 594, 63–68 (1999). https://doi.org/10.1557/PROC-594-63

Published:

Issue Date:

DOI: https://doi.org/10.1557/PROC-594-63