Abstract

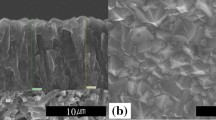

This paper reports on the effect of colloidal abrasive particle size in the polishing of thermally grown silicon dioxide on 100mm diameter, P-type, (100), single crystal silicon wafers. The abrasive particle sizes were varied in six (6) slurries with pH values of 10.97 ± 0.08. The abrasive sizes were 10, 20, 50, 80, 110 and 140nm in diameter, and the slurry contained 30 weight percent abrasives. The experimental results indicate that the material removal rate (MRR) varies with the volume of the particle size. Results also confirm that there exists an optimum abrasive particle size with respect to material removal rate and surface finish. For a pad surface roughness of 5.2μm (Ra), the slurry containing 80nm particles resulted in the highest material removal rate and best surface finish. A nano-film model based on the pad roughness is used to explain the results.

Similar content being viewed by others

References

M. Tomozawa, Solid State Technology, No. 7, pp. 169–175, 1997.

S.P. Murarka, Mat. Res. Soc. Symp. Proc., V. 566, pp. 3–11, 2000.

F. Preston, Journal of the Society of Glass Technology, V. 11, p. 214, 1927.

R. Jairath, M. Desai, M. Stell, R. Tolles, and D. Scherber-Brewer, Mat. Res. Soc. Sy mp. Proc., V. 337, pp. 121–131, 1994.

Y. Xie and B. Bhushan, Wear, V. 200, pp. 281–295, 1996.

T. Izumitani, Treatise on Materials Science and Technology, edited by M. Tomozawa and R. Doremus, Academic Press, V. 17, p. 115, 1979.

M. Bielmann, U. Mahajan, and R.K. Singh, Electrochemical and Solid-State Letters, V. 2, pp. 401–403, 1999.

L.M. Cook, Journal of Non-Crystalline Solids, V. 120, pp. 152, 1990.

U. Mahajan, S.M. Lee, and R.K. Singh, Proc. of the International Symp. on Chemical Mechanical Planarization in IC Device Manufacturing III, V. 99-37, pp. 396–401, 2000.

D.C. Koopman, WSRC-TR-2000-00239, Reversion 0, 2000.

L. Shan, C. Zhou, and S. Danyluk, IEEE Semiconductor Manufacturing, Accepted, 2001.

I.M. Hutchings, Tribology, Friction and Wear of Engineering Materials, CRC Press, pp. 136–142, 1992.

J. A. Greenwood and J. B. P. Williamson, Proc. Roy. Soc. London, A295, pp. 300–319, 1966.

B.J. Hamrock, Fundamentals of Fluid Film Lubrication, McGraw-Hill, p. 141, 1994.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Zhou, C., Shan, L., Ng, S.H. et al. Effects of Nano-scale Colloidal Abrasive Particle Size on SiO2 by Chemical Mechanical Polishing. MRS Online Proceedings Library 671, 16 (2001). https://doi.org/10.1557/PROC-671-M1.6

Published:

DOI: https://doi.org/10.1557/PROC-671-M1.6