Abstract

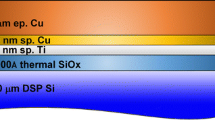

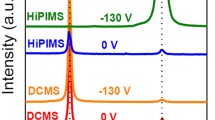

Copper films of different thicknesses between 0.2 and 2 microns were electroplated on adhesion-promoting TiW and Ta barrier layers on <100> single crystal 6-inch silicon wafers. The residual stress was measured after each processing step using a wafer curvature technique employing Stoney’s equation. Large gradients in the stress distributions were found across each wafer. Controlled Cu grain growth was achieved by annealing films at 350 C for 3 minutes in high vacuum. Annealing increased the average tensile residual stress by about 200 MPa for all the films, which is in agreement with stress-temperature cycling measurements.

After aging for 1 year wafer stress mapping showed that the stress gradients in the copper films were alleviated. No stress discrepancies between the copper on Ta and TiW barrier layers could be found. However, X-ray pole figure analysis showed broad and shifted (111) texture in films on a TiW underlayer, whereas the (111) texture in Cu films on Ta is sharp and centered.

Similar content being viewed by others

References

W.D. Nix, Metall. Trans. A, 20A, pp. 2217–2245, (1989)

Y. Wei and J.W. Hutchinson, J. Mech. Phys. Solids, 45 (7), pp. 1137–1159, (1997)

D.D. Brown, P. Borgesen, D.A. Lilienfeld, M.A. Korhonen and C.Y. Li, Mat. Res. Soc. Symp. Proc. Vol. 239, pp. 701–706, (1993)

H. Toyoda, P.-H. Wang, P. S. Ho, in Proceedings of the International Reliability Physics Symposium in 1998, (IEEE, Piscataway, 1998), pp. 324–328.

E. Zschech, W. Blum, I Zienert, P. R. Besser, Z Metallkd. 92, pp. 803–809, (2001)

R. Rosenberg, D. C. Edelstein, C.-K. Hu, K. P. Rodbell, Annual Review of Materials Sciences, (2000)

K. Ueno, T. Ritzdorf, S. Grace, J. Appl. Phys. 86 (9), pp. 4930–4935, (1999)

S. H. Brongersma, E. Richard, I. Vervoort, H. Bender, W. Vandervorst, S. Lagrange, G. Beyer, K. Maex, J. Appl. Phys. 86 (7), pp. 3642–3645, (1999)

M. Hauschildt, M.S. thesis, The University of Texas at Austin, (1999)

Frontier Semiconductor Measurements Inc., FSM 128&128L Operation Manual Rev. 4/98

M. Doerner and W. Nix, J. Mater. Res. 1, p. 601, (1986)

G.M. Pharr, W.C. Oliver, F. Brotzen, J. Mater. Res., 7 (3), pp. 613–617, (1992)

W.C. Oliver and G.M. Pharr, J. Mater. Res., 7, pp. 1564–1583, (1992)

A.A. Volinsky, J. Vella, I.S. Adhihetty, V. Sarihan, L. Mercado, B.H. Yeung, W.W. Gerberich, Mat. Res. Soc. Symp. Proc. Vol. 649, (2000)

R.P. Vinci, E.M. Zielinski, J.C. Bravman, Thin Solid Films 262, pp. 142–153, (1995)

G. Gottstein, Acta Metall. 32 (7), 1117–1138, (1984)

M. Hauschildt, E. T. Ogawa, S.-H. Rhee, D. Gan, P. S. Ho, to be published in Mater. Res. Soc. Symp. Proc., (2001)

D. P. Tracy, D. B. Knorr, K. P. Rodbell, J. Appl. Phys. 76 (5), (1994) pp. 2671–2680

E. M Zielinski, Ph. D. thesis, Stanford University, (1995)

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Volinsky, A.A., Hauschildt, M., Vella, J.B. et al. Residual Stress and Microstructure of Electroplated Cu Film on Different Barrier Layers. MRS Online Proceedings Library 695, 1111 (2001). https://doi.org/10.1557/PROC-695-L1.11.1

Published:

DOI: https://doi.org/10.1557/PROC-695-L1.11.1