Abstract

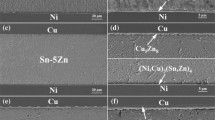

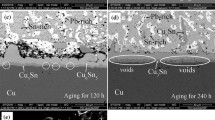

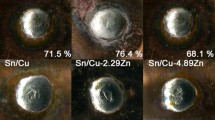

Sn–Zn-based alloys are promising low melting-point Pb-free solders, and it has been reported that their wetting properties and oxidation resistance can be improved with the addition of Cu. The interfacial reactions in the Sn–9 wt% Zn–xCu/Cu couples at 250 °C and Sn–9 wt% Zn–xCu/Ni at 280 °C were examined in this study. A thick γ–Cu5Zn8 phase layer and a very thin β′–CuZn phase layer were formed in both the Sn–9 wt% Zn/Cu and the Sn–9 wt% Zn–1 wt% Cu/Cu couples. The γ–Ni5Zn21 phase layer was formed in both the Sn–9 wt% Zn/Ni and Sn–9 wt% Zn–1 wt% Cu/Ni couples. With longer reaction time, the δ–Ni3Sn4 phase were formed in the Sn–9 wt% Zn/Ni couple as well. In both the Cu and Ni couples, the Zn-containing γ phases were uniform and planar and were the dominant reaction products. However, when the Cu content of the Sn–9 wt% Zn–xCu solders was 10 wt%, the interfacial reaction product becomes the η–Cu6Sn5 phase in both the Cu and Ni couples.

Similar content being viewed by others

References

Directive 2002/95/EC of the European Parliament and of the Council of 27 January 2003: On the restriction of the use of certain hazardous substances in electronic equipment. Official J. Eur. Union L37/19 (2003).

Lead-free assembly projects, National Electronics Manufacturing Initiatives (NEMI): Herndon, VA. http://www.nemi.org/projects/ese/lf_assembly.html (1999).

Roadmap 2002 for Commercialization of Lead-free Solder, Lead-Free Soldering Roadmap Committee, Technical Standardization Committee on Electronics Assembly Technology, Japan Electronics and Information Technology Industries Association (JEITA), Tokyo, Japan (2002).

M.E. Loomans, S. Vaynman, G. Ghosh, M.E. Fine: Investigation of multi-component lead-free solders. J. Electron. Mater. 23, 741 (1994).

C.W. Huang, K.L. Lin: Wetting properties of and interfacial reactions in lead-free Sn–Zn based solders on Cu and Cu plated with an electroless Ni–P/Au layer. Mater. Trans. 45, 588 (2004).

D.Q. Yu, H.P. Xie, L. Wang: Investigation of interfacial microstructure and wetting property of newly developed Sn–Zn–Cu solders with Cu substrate. J. Alloys Compd. 385, 119 (2004).

Y.C. Chan, M.Y. Chiu, T.H. Chung: Intermetallic compounds formed during the soldering reactions of eutectic Sn–9Zn with Cu and Ni substrates. Z. Metallkde. 93(2), 95 (2002).

K. Suganuma, K. Niihara, T. Shoutoku, Y. Nakamura: Wetting and interface microstructure between Sn–Zn binary alloys and Cu. J. Mater. Res. 13, 2859 (1998).

H.M. Lee, S.W. Yoon, B.J. Lee: Thermodynamic prediction of interface phases at Cu/solder joints. J. Electron. Mater. 27, 1161 (1998).

K. Suganuma, T. Murata, H. Noguchi, Y. Toyoda: Heat resistance of Sn–9Zn solder/Cu interface with or without coating. J. Mater. Res. 15,884 (2000).

C.W. Huang, K.L. Lin: Interfacial reactions of lead-free Sn–Zn based solders on Cu and Cu plated electroless Ni–P/Au layer under aging at 150 °C. J. Mater. Res. 19(12), 3560 (2004).

C.Y. Chou, S.W. Chen: Phase equilibria of the Sn–Zn–Cu ternary system. Acta Mater. 54(9), 2393 (2006).

R. Hultgren, P.D. Desai, D.T. Hawkins, M. Gleiser, K.K. Kelley: Selected Values of the Thermodynamic Properties of Binary Alloys (American Society for Metals, Washington, DC, 1973), p. 816.

E.A. Brandes, G.B. Brook: Smithells Metals Reference Book (Butterworth Heinemann, Oxford, UK, 1992).

L.H. Su, Y.W. Yen, S.W. Chen: Interfacial reactions in molten Sn/Cu and molten In/Cu couples. Metall. Mater. Trans. 28B, 927 (1997).

R.A. Gagliano, M.E. Fine: Thickening kinetics of interfacial Cu6Sn5 and Cu3Sn layers during reaction of liquid tin with solid copper. J. Electron. Mater. 32, 1441 (2003).

S.W. Chen, S.H. Wu, S.W. Lee: Interfacial reactions in the Sn–(Cu)/Ni, Sn–(Ni)/Cu, and Sn/(Cu, Ni) systems. J. Electron. Mater. 32, 1188 (2003).

J. Gorlich, G. Schmitz, K.N. Tu: On the mechanism of the binary Cu/Sn solder reaction. Appl. Phys. Lett. 86, 053106 (2005).

M. Abtew, G. Selvaduray: Lead-free solders in microelectronics. Mater. Sci. Eng. R 27, 95 (2000).

M.Y. Chiu, S.S. Wang, T.H. Chuang: Intermetallic compounds formed during interfacial reactions between liquid Sn–8Zn–3Bi solders and Ni substrate. J. Electron. Mater. 31, 494 (2002).

S.W. Chen, C.A. Chang: Phase equilibria of the Sn–Ag–Cu–Ni quaternary system at the Sn-rich corner. J. Electron. Mater. 33, 1071 (2004).

C.H. Lin, S.W. Chen, C.H. Wang: Phase equilibria and solidification properties of Sn–Cu–Ni alloys. J. Electron. Mater. 31, 907 (2002).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chou, Cy., Chen, Sw. & Chang, Ys. Interfacial reactions in the Sn–9Zn–(xCu)/Cu and Sn–9Zn–(xCu)/Ni couples. Journal of Materials Research 21, 1849–1856 (2006). https://doi.org/10.1557/jmr.2006.0229

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2006.0229