Abstract

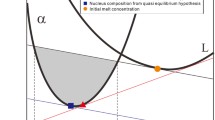

A framework is presented for modeling the nucleation in the constitutionally supercooled liquid ahead of the advancing solid/liquid interface. The effects of temperature gradient, imposed velocity, slope of liquidus, and initial concentration have been taken into account in this model by considering the effect of interface retardation, which is caused by solute buildup at the interface. Furthermore, the effect of solute concentration on the chemical driving force for nucleation has been considered in this model. The model is used for describing the nucleation of Al–Si and Al–Cu alloys. It was found that the solute of Si has a significant impact on the chemical driving force for nucleation in Al–Si alloys whereas Cu has almost no effect in Al–Cu alloys.

Similar content being viewed by others

References

W. Kurz, D. Fisher: Fundamentals of Solidification (Trans. Tech. Publ., Aedermannsdorf, Switzerland, 1985), p. 54.

W.A. Tiller, K.A. Jackson, J.W. Rutter, B. Chalmers: The redistribution of solute atoms during the solidification of metals. Acta Metall. 1, 428 (1953).

V.G. Smith, W.A. Tiller, J.W. Rutter: A mathematical analysis of solute redistribution during solidification. Canadian J. Phys. 33, 723 (1955).

W.D. Huang, Q.M. Wei, Y.H. Zhou: Nonsteady solute redistribution during the transient process of alloy solidification. J. Cryst. Growth 100, 26 (1990).

J.A. Warren, J.S. Langer: Prediction of dendritic spacings in a directional-solidification experiment. Phys. Rev. E 47, 2702 (1993).

H.G. Lee: Chemical Thermodynamics for Metals and Materials (Imperial College Press, UK, 1999), p. 6.69, Appendix I.

W.V. Youdelis: Nucleation entropy and supercooling in alloys. Metal Sci. 9, 464 (1975).

C.W. Bale, A.D. Pelton, W.T. Thompson: Facility for the Analysis of Chemical Thermodynamics (F*A*C*T*) (Ecole Polytechnique, Montreal, QC, Canada, 1996).

W.D. Huang, Y. Inatomi, K. Kuribayashi: Initial transient solute redistribution during directional solidification with liquid flow. J. Cryst. Growth 182, 212 (1997).

M. Johnsson, L. Backerud: The influence of composition on equiaxed crystal growth mechanisms and grain size in Al alloys. Z. Metallkd. 87, 216 (1996).

J. Hutt, D.H. StJohn, L. Hogan, A.K. Dahle: Equiaxed solidification of Al–Si alloys. Mater. Sci. Technol. 15, 495 (1999).

X. Yao, A. K. Dahle, C. J. Davidson, D. H. StJohn: Modeling of grain size transition with alloy concentration in solidified Al–Si alloys (2006, unpublished).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yao, X., Dahle, A.K., Davidson, C.J. et al. Effect of solute on the growth rate and the constitutional undercooling ahead of the advancing interface during solidification of an alloy and the implications for nucleation. Journal of Materials Research 21, 2470–2479 (2006). https://doi.org/10.1557/jmr.2006.0302

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2006.0302