Abstract

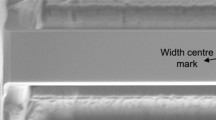

Focused ion beam machining was used to manufacture microcantilevers 30 µm by 3 µm by 4 µm with a triangular cross section in single crystal copper at a range of orientations between. These were imaged and tested using AFM/nanoindentation. Each cantilever was indented multiple times at a decreasing distance away from the fixed end. Variation of the beam’s behavior with loading position allowed a critical aspect ratio (loaded length:beam width) of 6 to be identified above which simple beam approximations could be used to calculate Young’s modulus. Microcantilevers were also milled within a single grain in a polycrystalline copper sample and electron backscattered diffraction was used to identify the direction of the long axis of the cantilever. The experimentally measured values of Young’s modulus and their variation with orientation were found to be in good agreement with the values calculated from the literature data for bulk copper.

Similar content being viewed by others

References

I.G. Ritchie: Improved resonant bar techniques for measurement of dynamic elastic-moduli and test of Timoshenko beam theory. J. Sound Vib. 31(4), 453 (1973).

H. Ledbetter: Dynamic vs static Young moduli: A case study. Mater. Sci. Eng., A 165(1), L9 (1993).

D.B. Sirdeshmukh and K.G. Subhadra: Consistency checks on elastic properties of crystals. J. Mater. Sci. 40(7), 1553 (2005).

R.J. Talling, R.J. Dashwood, M. Jackson, S. Kurarnoto, and D. Dye: Determination of (C-11-C-12) in Ti-36Nb-2Ta-3Zr-0.3O (wt%) (gum metal). Scr. Mater. 59(6), 669 (2008).

W.C. Oliver and G.M. Pharr: An improved technique for determining hardness and elastic-modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7(6), 1564 (1992).

W.C. Oliver and G.M. Pharr: Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 19(1), 3 (2004).

J.J. Vlassak and W.D. Nix: Measuring the elastic properties of anisotropic materials by means of indentation experiments. J. Mech. Phys. Solids 42(8), 1223 (1994).

D. Di Maio and S.G. Roberts: Measuring fracture toughness of coatings using focused-ion-beam-machined microbeams. J. Mater. Res. 20(2), 299 (2005).

D. Kiener, W. Grosinger, G. Dehm, and R. Pippan: A further step towards an understanding of size-dependent crystal plasticity: In situ tension experiments of miniaturized single-crystal copper samples. Acta Mater. 56(3), 580 (2008).

D. Kiener, C. Motz, T. Schoberl, M. Jenko, and G. Dehm: Determination of mechanical properties of copper at the micron scale. Adv. Eng. Mater. 8(11), 1119 (2006).

M.D. Uchic, D.M. Dimiduk, J.N. Florando, and W.D. Nix: Sample dimensions influence strength and crystal plasticity. Science 305(5686), 986 (2004).

S. Johansson, J.A. Schweitz, L. Tenerz, and J. Tiren: Fracture testing of silicon microelements in situ in a scanning electronmicroscope. J. Appl. Phys. 63(10), 4799 (1988).

T.P. Weihs, S. Hong, J.C. Bravman, and W.D. Nix: Mechanical deflection of cantilever microbeamsA new technique for testing the mechanical-properties of thin-films. J. Mater. Res. 3(5), 931 (1988).

M.D. Uchic and D.A. Dimiduk: A methodology to investigate size scale effects in crystalline plasticity using uniaxial compression testing. Mater. Sci. Eng., A 400, 268 (2005).

K.S. Ng and A.H.W. Ngan: Stochastic nature of plasticity of aluminum micro-pillars. Acta Mater. 56(8), 1712 (2008).

C.P. Frick, B.G. Clark, S. Orso, A.S. Schneider, and E. Arzt: Size effect on strength and strain hardening of small-scale [111] nickel compression pillars. Mater. Sci. Eng., A 489(12), 319 (2008).

M.D. Uchic, D.M. Dimiduk, R. Wheeler, P.A. Shade, and H.L. Fraser: Application of micro-sample testing to study fundamental aspects of plastic flow. Scr. Mater. 54(5), 759 (2006).

J.R. Greer and W.D. Nix: Size dependence of mechanical properties of gold at the sub-micron scale. Appl. Phys. A 80(8), 1625 (2005).

J.R. Greer and W.D. Nix: Nanoscale gold pillars strengthened through dislocation starvation. Phys. Rev. B 73(24), 245410 (2006).

C.A. Volkert, E.T. Lilleodden, D. Kramer, and J. Weissmuller: Approaching the theoretical strength in nanoporous Au. Appl. Phys. Lett. 89(6), 061920 (2006).

D. Kiener, C. Motz, and G. Dehm: Dislocation-induced crystal rotations in micro-compressed single crystal copper columns. J. Mater. Sci. 43(7), 2503 (2008).

Y.H. Lai, C.J. Lee, Y.T. Cheng, H.S. Chou, H.M. Chen, X.H. Du, C.I. Chang, J.C. Huang, S.R. Jian, J.S.C. Jang, and T.G. Nieh: Bulk and microscale compressive behavior of a Zr-based metallic glass. Scr. Mater. 58(10), 890 (2008).

B.E. Schuster, Q. Wei, T.C. Hufnagel, and K.T. Ramesh: Sizeindependent strength and deformation mode in compression of a Pd-based metallic glass. Acta Mater. 56(18), 5091 (2008).

E.M. Nadgorny, D.M. Dimiduk, and M.D. Uchic: Size effects in LiF micron-scale single crystals of low dislocation density. J. Mater. Res. 23(11), 2829 (2008).

S. Shim, H. Bei, M.K. Miller, G.M. Pharr, and E.P. George: Effects of focused-ion-beam milling on the compressive behavior of directionally solidified micropillars and the nanoindentation response of an electropolished surface. Acta Mater. 57(2), 503 (2009).

C. Motz, T. Schoberl, and R. Pippan: Mechanical properties of micro-sized copper bending beams machined by the focused ion beam technique. Acta Mater. 53(15), 4269 (2005).

S.G. Epstein and O.N. Carlson: Elastic constants of nickel-copper alloy single crystals. Acta Metall. 13(5), 487 (1965).

H.N. Ledbetter and E.R. Naimon: Elastic properties of copper. J. Phys. Chem. Ref. Data 3(4), 897 (1974).

E.H. Jacobsen: Elastic spectrum of copper from temperature scattering of x-rays. Phys. Rev. 94(5), 1420 (1954).

Y. Hiki and A.V. Granato: Anharmonicity in noble metals Higher order elastic constants. Phys. Rev. 144(2), 411 (1966).

R.F.S. Hearmon: The elastic constants of anisotropic materials. Rev. Mod. Phys. 18(3), 409 (1946).

R.F.S. Hearmon: The elastic constants of anisotropic materials II. Adv. Phys. 5(19), 323 (1956).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Armstrong, D.E.J., Wilkinson, A.J. & Roberts, S.G. Measuring anisotropy in Young’s modulus of copper using microcantilever testing. Journal of Materials Research 24, 3268–3276 (2009). https://doi.org/10.1557/jmr.2009.0396

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2009.0396