Abstract

An instrumented indentation method is established to accurately measure the local elastic-plastic material properties of a single fiber by accounting for the additional sources of compliance associated with fiber indentation. The Oliver-Pharr instrumented indentation data analysis method is compared for indentation of a standard, planar fused silica sample and in the radial direction of homogeneous, isotropic E-glass fibers of two different diameters. Compliance contributions from substrate deflection and other nonindentation-related fiber deflections are quantified and shown to be negligible. The added compliance observed is attributed to the lack of constraint due to the finite geometry of a curved fiber surface. This compliance contribution is accounted for by using a proposed area correction to capture the geometry of the curved fiber-probe contact combined with a structural compliance correction. Implementation of these corrections to experimental indentation curves results in accurate measurements of the fiber elastic modulus and hardness.

Similar content being viewed by others

References

ASTM D 3379–75: Standard test method for tensile strength and Young’s modulus for high-modulus single-filament materials. DOI: 10.1520/D3379-75R89E01. ASTM International, West Conshohocken, PA, 1989.

M. Cheng, W.N. Chen, and T. Weerasooriya: Mechanical properties of Kevlar(R) KM2 single fiber. J. Eng. Mater. Technol. 127, 197 (2005).

S.J. Deteresa, S.R. Allen, R.J. Farris, and R.S. Porter: Compressive and torsional behaviour of Kevlar 49 fibre. J. Mater. Sci. 19, 57 (1984).

S. Kawabata: Measurement of the transverse mechanical properties of high performance fibers. J. Text. Inst. 81, 432 (1990).

D.L. Languerand, H. Zhang, N.S. Murthy, K.T. Ramesh, and F. Sansoz: Inelastic behavior and fracture of high modulus polymeric fiber bundles at high strain-rates. Mater. Sci. Eng., A 500, 216 (2009).

A.A. Leal, J.M. Deitzel, and J.W. Gillespie: Assessment of compressive properties of high performance organic fibers. Compos. Sci. Technol. 67, 2786 (2007).

A.A. Leal, J.M. Deitzel, and J.W. Gillespie: Compressive strength analysis for high performance fibers with different modulus in tension and compression. J. Compos. Mater. 43, 661 (2009).

K.G. Lee, R. Barton, and J.M. Schultz: Structure and property development in poly(p-phenylene terephthalamide) during heat treatment under tension. J. Polym. Sci., Part B: Polym. Phys. 33, 1 (1995).

C.T. Li and N.R. Langley: Improvement in fiber testing of high-modulus single filament materials. Commun. Am. Ceram. Soc. 68, C–202(1985).

Y. Rao, A.J. Waddon, and R.J. Farris: The evolution of structure and properties in poly(p-phenylene terephthalamide) fibers. Polymer 42, 5925 (2001).

J. Singletary, H. Davis, M.K. Ramasubramanian, W. Knoff, and M. Toney: The transverse compression of PPTA fibers part I: Single fiber transverse compression testing. J. Mater. Sci. 35, 573 (2000).

W.C. Oliver and G.M. Pharr: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564 (1992).

XP user’s manual. V. 16 (2002).

R.L. Hausrath and A.V. Longobardo: Chapter 5: High-strength glass fibers and markets, In Fiberglass and Glass Technology; F.T. Wallenberger and P.A. Bingham eds.; Springer Science + Business Media, LLC.: New York, 2010; p. 197.

ASTM D 578–05: Standard specification for glass fiber strands. DOI: 10.1520/D0578_D0578M-05R11E01. ASTM International, West Conshohocken, PA, 2011.

I.N. Sneddon: The relation between load and penetration in the axisymmetric Boussinesq problem for a punch of arbitrary profile. Int. J. Eng. Sci. 3, 47 (1965).

L.E. Samuels and T.O. Mulhearn: An experimental investigation of the deformed zone associated with indentation hardness impressions. J. Mech. Phys. Solids 5, 125 (1957).

G. Stan, S. Krylyuk, A.V. Davydov, M. Vaudin, L.A. Bendersky, and R.F. Cook: Surface effects on the elastic modulus of Te nanowires. Appl. Phys. Lett. 91, 231908 (2008).

G. Feng, W.D. Nix, Y. Yoon, and C.J. Lee: A study of the mechanical properties of nanowires using nanoindentation. J. Appl. Phys. 99, 074304 (2006).

N. Lonnroth, C.L. Muhlstein, C. Pantano, and Y. Yue: Nanoindentation of glass wool fibers. J. Non-Cryst. Solids. 354, 3887 (2008).

E.P.S. Tan and C.T. Lim: Nanoindentation study of nanofibers. Appl. Phys. Lett. 87, 123106 (2005).

J. Cayer-Barrioz, A. Tonck, D. Mazuyer, P.H. Kapsa, and A. Chateauminois: Nanoscale mechanical characterization of polymeric fibers. J. Polym. Sci., Part B: Polym. Phys. 43, 264 (2005).

G. Wei, B. Bharat, and P.M. Torgerson: Nanomechanical characterization of human hair using nanoindentation and SEM. Ultramicroscopy 105, 248 (2005).

X. Li, H. Gao, C.J. Murphy, and K.K. Caswell: Nanoindentation of silver nanowires. Nano Lett. 3, 1495 (2003).

X. Li, B. Bhushan, and P.B. McGinnis: Nanoscale mechanical characterization of glass fibers. Mater. Lett. 29, 215 (1996).

N.K. Chang, Y.S. Lin, C.Y. Chen, and S.H. Chang: Size effect of indenter on determining modulus of nanowires using nanoindentation. Thin Solid Films 517, 3695 (2009).

J.E. Jakes, C.R. Frihart, J.F. Beecher, R.J. Moon, and D.S. Stone: Experimental method to account for structural compliance in nanoindentation measurements. J. Mater. Res. 23, 1113 (2008).

J.E. Jakes and D.S. Stone: The edge effect in nanoindentation. Philos. Mag. 91, 1387 (2011).

D.S. Stone, K.B. Yoder, and W.D. Sproul: Hardness and elastic modulus of TiN based on continuous indentation technique and new correlation. J. Vac. Sci. Technol., A. 9, 2543 (1991).

D.L. Joslin and W.C. Oliver: A new method for analyzing data from continuous depth-sensing microindentation tests. J. Mater. Res. 5, 123 (1990).

J.E. Jakes: Private communication. (2010).

A.V. Longobardo: Private communication. (2010–2011).

M.R. VanLandingham, T.F. Juliano, and M.J. Hagon: Measuring tip shape for instrumented indentation using atomic force microscopy. Meas. Sci. Technol. 16, 2173 (2005).

K. Tai, D. Ming, S. Suresh, A. Palazoglu, and C. Ortiz: Nanoscale heterogeneity promotes energy dissipation in bone. Nat. Mater. 6, 454 (2007).

K.L. Johnson: Contact Mechanics, 1st ed. (Cambridge University Press, Cambridge, United Kingdom, 1985).

K.L. Johnson: The correlation of indentation experiments. J. Mech. Phys. Solids. 18, 115 (1970).

J. Chen and S.J. Bull: On the relationship between plastic zone radius and maximum depth during nanoindentation. Surf. Coat. Technol. 201, 4289 (2006).

N.A. Stilwell and D. Tabor: Elastic recovery of conical indentations. Proc. Phys. Soc. 78, 169 (1961).

T. Chudoba and N.M. Jennett: Higher accuracy analysis of instrumented indentation data obtained with pointed indenters. J. Phys. D: Appl. Phys. 41, 215407 (2008).

J.H. Strader, S. Shim, H. Bei, W.C. Oliver, and G.M. Pharr: An experimental evaluation of the constant β relating the contact stiffness to the contact area in nanoindentation. Philos. Mag. 86, 5285 (2006).

H. Hertz: On the contact of elastic solids. J. Reine Angew. Mathematik, 92, 156 (1882).

T. Juliano, Y. Gogotsi, and V. Domnich: Effect of indentation unloading conditions on phase transformation induced events in silicon. J. Mater. Res. 18, 1192 (2003).

T. Juliano, V. Domnich, T. Buchheit, and Y. Gogotsi: Numerical derivative analysis of load-displacement curves in depth-sensing indentation, In Mechanical Properties of Nanostructured Materials and Nanocomposites, I. Ovid’ko, C.S. Pande, R. Krishnamoorti, E. Lavernia, and G. Skandan eds.; Mater. Res. Soc. Symp. Proc. 791; Pennsylvania, 2004, Q7.5.1.

Acknowledgments

QM and JWG gratefully acknowledge sponsorship by the Army Research Laboratory under cooperative agreement W911NF-06-2-0011. The views and conclusions contained in this paper should not be interpreted as representing the official policies, either expressed or implied, of the Army Research Laboratory or the U.S. Government. The U.S. Government is authorized to reproduce and distribute reprints for Government purposes not withstanding any copyright notation hereon. The authors would also like to thank Dr. Kenneth Strawhecker for useful discussions in data interpretation, Dr. Joseph Deitzel for help in formulating a proper mounting system, and Dr. Anthony V. Longobardo for supplying the 10-μm E-glass samples and useful E-glass discussions.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix A—Projected Area Corrections for Radial Indentation of a Filament by Various Probes

A. Conical indentation probe

Define the fiber cross-section in Fig. A1 by a circle of radius R centered at (0,0):

Both ac and d can be defined in terms of the indent depth and indenter and fiber geometry:

Substituting (A3) and (A4) back into (A2), expanding, and combining like terms gives h′c in quadratic form:

Using the quadratic formula, a solution for\(h'_{\rm{c}} \) is found:

Recognizing (tan2θ + 1) = sec2θ = 1/cos2θ, and dividing through by hc gives the\(h'_{\rm{c}} /h_{\rm{c}} \) solution for a cone:

The elliptical area correction can be found in two manners: 1) considering an ideally shaped probe, and 2) staying consistent with the experiment, and using the calibrated probe area function. The first method depends heavily on the general probe shape used. For a cone, consider the area of an ellipse to be Aellipse = πab. The major elliptical radius, a, is along the fiber axial direction and is given by, af; and the minor elliptical radius, b, falls along the curved transverse profile and given by ac. Therefore:

Comparing this to the area function for a circular projection on a flat surface,\(A_\text{flat} = \pi a_\text{f}^2,\) gives:

The second method gives a solution that is interchangeable for all probe shapes as long as the probe area function, A, is known. This is the method used herein:

From these relationships it follows that:

Now using (A8) for Aellipse, the general area correction ratio is:

B. Spherical indentation probe

Define the fiber cross section in Fig. A2 as a circle of radius R centered at (0, 0) and the probe as a circle of radius r centered at (0, R + r–hc):

The y of interest is that where the fiber and the probe share the same x, or x2:

Expanding, simplifying, and solving for y gives:

Using the relationship,\(R - h_{\rm{c}} = y - h'_{\rm{c}} \) gives\(h'_{\rm{c}} = y - R + h_{\rm{c}},\) and dividing through by hc gives:

The area correction for a spherical probe can be done using either the general Eq. (A17) or assuming an ideal spherical probe. For an ideal spherical probe, af and ac are:

Then the area correction ratio is given as:

C. Spheroconical indentation probe

The spheroconical probe contact correction can be best described by a piecewise function separated at the transition point between spherical and conical probe shape. This transition point is at the tangent point between line 1 defined by the conical region of the probe and the spherical end of the probe defined by radius r (Fig. A3). The tangent point, (x1, y1) will be where the slopes are equal. The slope of line 1 is given by cot(θ), and the spherical portion of the probe can be defined as x2 + y2 = r2 which gives a slope, dy/dx:

The slopes are found to be equal when x1 = rcosθ and y1 = rsinθ. This point can be used to find the intersection of lines 1 and 2, which gives y2. The lines are defined as:

From the schematic, y1 = y2 = y2 when x = 0. Therefore,

The distance hd is the indent depth lost due to the rounding of a conical tip, and is given by:

The relationship between\(h'_{\rm{c}} \) and hc for a spheroconical tip is then given by the spherical relationship (A22) at depths below the sphere-cone transition depth of\(r - \left| {y_1 } \right|\), or hc < r(1 − sinθ). At depths greater than r(1 − sinθ), the conical relationship (A7) can be used by substituting\(h'_{\rm{c}} + h_{\rm{d}} \) for\(h'_{\rm{c}} \) and hc+ hd for hc, giving:

With simplification, this ultimately gives the piecewise function for\(h'_{\rm{c}} /h_{\rm{c}} \) of a spheroconical probe governed by the sphere at low depths and a cone at greater depths:

Similarly, the corrected area can be found using Eq. (A17) using the calibrated probe area function; or for an ideal spheroconical probe the area is given by that of a sphere at indent contact depth hc at low depths and by a cone at an indent contact depth hc + hd at greater depths:

Appendix B—Sys Plots of The E-Glass Fibers

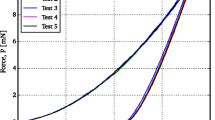

The correction for structural compliance used when measuring the material properties of the glass fibers is extracted from the SYS plots for the 10- and 23-μm fibers portrayed below. The plots show one representative SYS curve for each indentation depth on each fiber.

The correlation depth indicated in Fig. A4 corresponds to the probe transition from spherical to conical in shape. This transition limits the linear fit region to contact depths greater than approximately 290 nm33 and restricts the SYS parameter measurements on the 10-μm fiber to only the maximum indent depth of 800 nm. Beyond this depth, the SYS compliance plots are linear, indicating that the sources of compliance associated with fiber indentation are independent of indent load, and validating the use of the Jakes et al. compliance method. The values for Cs and Jo, in Table I, are averages for all the applicable indents [i.e., five (5) 800 nm indents on the 10-μm fiber and five at each depth totaling twenty (20) on the 23-μm fiber]. The ranges given in Table I are representative of one standard deviation of the applicable measurements.

Based solely on the geometry of the probe-fiber contact, the relative constraining volume decreases with indent depth, which would cause an increase in the structural compliance with indent depth. Conversely, in Fig. A4, the structural compliance (slope of the SYS plot) decreases until it reaches an approximately constant value at greater indent depths (loads). Our preliminary understanding is that stress contour modifications and the material pile-up around the indenter appear to mitigate the curvature such that the structural compliance reaches a plateau value.

Rights and permissions

About this article

Cite this article

McAllister, Q.P., Gillespie, J.W. & VanLandingham, M.R. Nonlinear indentation of fibers. Journal of Materials Research 27, 197–213 (2012). https://doi.org/10.1557/jmr.2011.336

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2011.336