Abstract

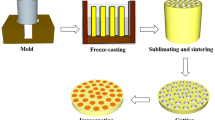

We have used a hydrogel templating technique followed by the subsequent evaporation of water present to fabricate porous cement and porous PDMS composites, and we have analyzed their sound absorption properties. All experiments were carried out with hydrogel slurries of broad bead size distributions. Porous PDMS and cement composites were produced with porosities of up to 80% and 70%, respectively. Scanning electron microscope analysis shows fibrous domains within the voids created by the hydrogel in the cement samples and open pore network in the PDMS composites of initial hydrogel content higher than 70 vol%. Sound absorption was improved with respect to control nonporous samples in all composites with porosities higher than 60 vol%, where an open pore structure was formed. The porous PDMS and porous cement produced by this method show better sound absorption at 200–400 Hz and 1200–1800 Hz frequency ranges when compared with the sound absorption in the intermediate frequencies range between 400 and 1000 Hz.

Similar content being viewed by others

References

W. Passchier-Vermeer and W.F. Passchier: Noise exposure and public health. Environ. Health Perspect. 108, 123 (2000).

J.P. Arenas and M.J. Crocker: Recent trends in porous sound-absorbing materials. J. Sound Vib. 44(7), 12 (2010).

L.L. Beranek and I.L. Vér: Noise and Vibration Control Engineering: Principles and Applications (John Wiley & Sons, New York, NY, 1992).

M.J. Crocker: Handbook of Noise and Vibration Control (John Wiley & Sons, Hoboken, NJ, 2007).

M.R.F. Kidner and C.H. Hansen: A comparison and review of theories of the acoustics of porous materials. Int. J. Acoust. Vibr. 13(3), 112 (2008).

M.E. Delany and E.N. Bazley: Acoustical properties of fibrous absorbent materials. Appl. Acoust. 3(2), 105 (1970).

T.J. Cox and P. D'Antonio: Acoustic Absorbers and Diffusers: Theory, Design and Application (Taylor & Francis, London, UK, 2004).

F.J. Fahy: Foundations of Engineering Acoustics (Elsevier Science, London, UK, 2000).

N. Atalla, R. Panneton, F.C. Sgard, and X. Olny: Acoustic absorption of macro-perforated porous materials. J. Sound Vib. 243(4), 659 (2001).

D. Cuiyun, C. Guang, X. Xinbang, and L. Peisheng: Sound absorption characteristics of a high-temperature sintering porous ceramic material. Appl. Acoust. 73(9), 865 (2012).

N.N. Najib, Z.M. Ariff, A.A. Bakar, and C.S. Sipaut: Correlation between the acoustic and dynamic mechanical properties of natural rubber foam: Effect of foaming temperature. Mater. Des. 32(2), 505 (2011).

Y.H. Ng and L. Hong: Acoustic attenuation characteristics of surface-modified polymeric porous microspheres. J. Appl. Polym. Sci. 102(2), 1202 (2006).

N.D. Yilmaz, P. Banks-Lee, N.B. Powell, and S. Michielsen: Effects of porosity, fiber size, and layering sequence on sound absorption performance of needle-punched nonwovens. J. Appl. Polym. Sci. 121(5), 3056 (2011).

H. Olms and B. Breuer: Tire/road-noise trailer measurements with the close-proximity method under variation of accelerating and braking torque. Inter-Noise 99: Proceedings of the 1999 International Congress on Noise Control Engineering, Vols. 1–3, 1999. p. 213.

J. Kang and M.W. Brocklesby: Feasibility of applying micro-perforated absorbers in acoustic window systems. Appl. Acoust. 66(6), 669 (2005).

H.K. Kim, J.H. Jeon, and H.K. Lee: Workability, and mechanical, acoustic and thermal properties of lightweight aggregate concrete with a high volume of entrained air. Constr. Build. Mater. 29(0), 193 (2012).

K. Van Vliet, R. Pellenq, M.J. Buehler, J.C. Grossman, H. Jennings, F-J. Ulm, and S. Yip: Set in stone? A perspective on the concrete sustainability challenge. MRS Bull. 37(04), 395 (2012).

M. Rutkevičius, S.K. Munusami, Z. Watson, A.D. Field, M. Salt, S.D. Stoyanov, J. Petkov, G.H. Mehl, and V.N. Paunov: Fabrication of novel lightweight composites by a hydrogel templating technique. Mater. Res. Bull. 47(4), 980 (2012).

ISO 10534-1: Acoustics: Determination of Sound Absorption Coefficient and Impedance in Impedance Tubes. Part 1: Method Using Standing Wave Ratio (International Standards Organisation, Geneva, Switzerland, 1996).

N.M. Alford and A.A. Rahman: An assesment of porosity and pore sizes in hardened cement pastes. J. Mater. Sci. 16(11), 3105 (1981).

Acknowledgments

M.R. appreciates the Industrial CASE PhD studentship from the EPSRC and Unilever for this study. We also thank the University of Hull for the partial support of this study and Mr Nigel Parkin for the fabrication of the cylindrical molds.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Rutkevičius, M., Mehl, G.H., Paunov, V.N. et al. Sound absorption properties of porous composites fabricated by a hydrogel templating technique. Journal of Materials Research 28, 2409–2414 (2013). https://doi.org/10.1557/jmr.2013.194

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2013.194