Abstract

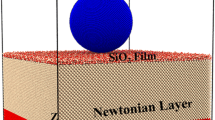

Nanoindentation was performed on amorphous silicon nitride films of different thicknesses deposited on gallium arsenide (GaAs) (001) substrates using a conical indenter. Both “pop-in” and ‘pop-out’ were observed from the load-displacement curves when the indentation load exceeded a critical value. Pop-in occurring during loading is associated with plane-slip in the GaAs substrate, and pop-out during unloading is attributed to the interfacial delamination between the film and the substrate. Finite element modeling (FEM) was used to analyze the stress evolution during unloading. The FEM results showed that the stress at the interface evolved from compressive to tensile status during the withdrawal of indentation load, and the interfacial debonding was induced at a critical tensile stress, which is consistent with the pop-out observed. A deformation model for interpreting the pop-in and pop-out events is thereby proposed.

Similar content being viewed by others

References

F.W. Smith, H.Q. Le, V. Diadiuk, M.A. Hollis, A.R. Calawa, S. Gupta, M. Frankel, D.R. Dykaar, G.A. Mourou, and T.Y. Hsiang: Picosecond GaAs-based photoconductive optoelectronic detectors. Appl. Phys. Lett. 54, 890 (1989).

D.K.W. Lam and R.I. Macdonald: GaAs optoelectronic mixer operation at 4.5 GHz. IEEE Trans. Electron Devices 31, 1766 (1984).

Y. Saito, T. Isozaki, A. Masuda, K. Fukumoto, M. Chosa, T. Ito, C.E. Bauer, A. Inspektor, and E.J. Oles: Adhesion strength of diamond film on cemented carbide insert. Diamond Relat. Mater. 2, 1391 (1993).

J. Yota: Interlevel dielectric processes using PECVD silicon nitride, polyimide, and polybenzoxazole for GaAs HBT technology. J. Electrochem. Soc. 156, G173 (2009).

I. Hallakoun, I. Toledo, J. Kaplun, G. Bunin, M. Leibovitch, and Y. Shapira: Critical dimension improvement of plasma enhanced chemical vapor deposition silicon nitride thin films in GaAs devices. Mater. Sci. Eng., B 102, 352 (2003).

M. Gioti, S. Logothetidis, and C. Charitidis: Stress relaxation and stability in thick amorphous carbon films deposited in layer structure. Appl. Phys. Lett. 73, 184 (1998).

S-Y. Chang, H-C. Tsai, J-Y. Chang, S-J. Lin, and Y-S. Chang: Analyses of interface adhesion between porous SiOCH low-k film and SiCN layers by nanoindentation and nanoscratch tests. Thin Solid Films 516, 5334 (2008).

E.Y. Chang, G.T. Cibuzar, J.M. Vanhove, R.M. Nagarajan, and K.P. Pande: GaAs devices passivation using sputtered silicon nitride. Appl. Phys. Lett. 53, 1638 (1988).

A. Jaouad, V. Aimez, and C. Aktik: GaAs passivation by low-frequency plasma- enhanced chemical vapor deposition of silicon nitride. Electron. Lett. 40, 1024 (2004).

K.B. Yeap, K.Y. Zeng, H.Y. Jiang, L. Shen, and D.Z. Chi: Determining interfacial properties of submicron low-k films on Si substrate by using wedge indentation technique. J. Appl. Phys. 101, 123531 (2007).

R.K. Singh, M.T. Tilbrook, Z.H. Xie, A. Bendavid, P.J. Martin, P. Munroe, and M. Hoffman: Contact damage evolution in diamond-like carbon coatings on ductile substrates. J. Mater. Res. 23, 27 (2008).

S.J. Bull: Failure modes in scratch adhesion testing. Surf. Coat. Technol. 50, 25 (1991).

A.J. Perry: Scratch adhesion testing of hard coatings. Thin Solid Films 107, 167 (1983).

J.J. Chen and S.J. Bull: Approaches to investigate delamination and interfacial toughness in coated systems: An overview. J. Phys. D: Appl. Phys. 44(3), 034001 (2011).

A.A. Volinsky, N.R. Moody, and W.W. Gerberich: Interfacial toughness measurements for thin films on substrates. Acta Mater. 50, 441 (2002).

S. Zhang, Y.S. Wang, X.T. Zeng, K.A. Khor, W.J. Weng, and D.E. Sun: Evaluation of adhesion strength and toughness of fluoridated hydroxyapatite coatings. Thin Solid Films 516, 5162 (2008).

R. Jacobsson: Measurement of the adhesion of thin films. Thin Solid Films 34, 191 (1976).

D. Hegemann, H. Brunner, and C. Oehr: Plasma treatment of polymers for surface and adhesion improvement. Nucl. Instrum. Methods 208, 281 (2003).

J. Kim, K.S. Kim, and Y.H. Kim: Mechanical effects in peel adhesion test. J. Adhes. Sci. Technol. 3, 175 (1989).

R.H. Dauskardt, M. Lane, Q. Ma, and N. Krishna: Adhesion and debonding of multilayer thin film structures. Eng. Fract. Mech. 61, 141 (1998).

C. Litteken, R. Dauskardt, T. Scherban, G. Xu, J. Leu, D. Gracias, and B. Sun: Interfacial adhesion of thin-film patterned interconnect structures. In Proceedings of the IEEE 2003 International, New York, 2003 (IEEE, New York, NY, 2003); p. 168.

M.P. DeBoer and W.W. Gerberich: Microwedge indentation of the thin film fine line. 1. Mech. Acta Mater. 44, 3169 (1996).

M.P. DeBoer and W.W. Gerberich: Microwedge indentation of the thin film fine line. 2. Exp. Acta Mater. 44, 3177 (1996).

S. Zhang and X.M. Zhang: Toughness evaluation of hard coatings and thin films. Thin Solid Films 520, 2375 (2012).

H. Huang, K.J. Winchester, A. Suvorova, B.R. Lawn, Y. Liu, X.Z. Hu, J.M. Dell, and L. Faraone: Effect of deposition conditions on mechanical properties of low-temperature PECVD silicon nitride films. Mater. Sci. Eng., A 435, 453 (2006).

W.C. Oliver and G.M. Pharr: Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 19, 3 (2004).

H. Huang, K. Winchester, Y. Liu, X.Z. Hu, C.A. Musca, J.M. Dell, and L. Faraone: Determination of mechanical properties of PECVD silicon nitride thin films for tunable MEMS Fabry-Perot optical filters. J. Micromech. Microeng. 15, 608 (2005).

Y.G. Jung, B.R. Lawn, M. Martyniuk, H. Huang, and X.Z. Hu: Evaluation of elastic modulus and hardness of thin films by nanoindentation. J. Mater. Res. 19, 3076 (2004).

A. Needleman: A continuum model for void nucleation by inclusion debonding. J. Appl. Mech. Trans. ASME 54, 525 (1987).

ANSYS Academic Research Release 13.0, Help System, 4.13. Cohesive Zone Material Model, (ANSYS, Inc., 2007).

H.H. Sheng Liu and Y. Gu: Deconvolution of mechanical properties of thin films from nanoindentation measurement via finite element optimization. Thin Solid Films 526, 183 (2012).

E. Le Bourhis and G. Patriarche: Structure of nanoindentations in heavily n- and p-doped (001) GaAs. Acta Mater. 56(7), 1417 (2008).

E. Le Bourhis and G. Patriarche: Structure of annealed nanoindentations in n- and p-doped (001)GaAs. J. Appl. Phys. 106, 123516 (2009).

C.R. Taylor, A.P. Malshe, G. Salamo, R.N. Prince, L. Riester, and S.O. Cho: Characterization of ultra-low-load (mu N) nanoindents in GaAs(100) using a cube corner tip. Smart Mater. Struct. 14, 963 (2005).

J.E. Bradby, J.S. Williams, J. Wong-Leung, M.V. Swain, and P. Munroe: Mechanical deformation of InP and GaAs by spherical indentation. Appl. Phys. Lett. 78, 3235 (2001).

S.J. Lloyd, J.M. Molina-Aldareguia, and W.J. Clegg: Deformation under nanoindents in Si, Ge, and GaAs examined through transmission electron microscopy. J. Mater. Res. 16, 3347 (2001).

S.V. Hainsworth, M.R. McGurk, and T.F. Page: The effect of coating cracking on the indentation response of thin hard-coated systems. Surf. Coat. Technol. 102, 97 (1998).

J. Chen and S.J. Bull: Indentation fracture and toughness assessment for thin optical coatings on glass. J. Phys. D: Appl. Phys. 40, 5401 (2007).

J. Chen and S.J. Bull: Finite element analysis of contact induced adhesion failure in multilayer coatings with weak interfaces. Thin Solid Films 517(13), 3704 (2009).

Acknowledgments

The authors would like to acknowledge the financial support of WIN Semiconductors Co. and Australian Research Council (ARC). Mr. Dennis Williams and Dr. Jerome Wu are acknowledged for their valuable comments and TEM assistance. HH is financially supported by ARC under the Future Fellow Program.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lu, M., Xie, H., Huang, H. et al. Indentation-induced delamination of plasma-enhanced chemical vapor deposition silicon nitride film on gallium arsenide substrate. Journal of Materials Research 28, 1047–1055 (2013). https://doi.org/10.1557/jmr.2013.31

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2013.31