Abstract

Cu-based shape memory alloys (SMAs) and among these copper–zinc (Cu–Zn), copper–aluminum (Cu–Al), and copper–tin (Cu–Sn) alloys both with and without ternary additions have shown potential due to their good shape recovery, ease of fabrication, excellent conductivity of heat and electricity. However, their applications are still limited because of the shortcomings of thermal stability, brittleness, and mechanical strength, which are closely related with microstructural characteristic of Cu-based SMAs, such as coarse grain sizes, high elastic anisotropies, and the congregation of secondary phases or impurities along the grain boundaries. Efforts are being made to overcome these drawbacks with proper ternary additions, adopting alternative processing routes and also optimizing the heat treatment cycles. The present article will deal with the current status of research and commercialization of Cu-based SMAs and dwell upon the future directions in which research should be targeted and future prospects of converting the research into components for commercial use.

Similar content being viewed by others

References

J.D. Stice and C.M. Wayman: Observations of aging effects in a Cu-Sn shape memory alloy. Metall. Trans. A 13(10), 1687 (1982).

M. Kamal: Mechanical properties of rapidly solidified of Cu–Sn shape memory alloys. Radiat. Eff. Defects Solids 161(3), 189 (2006).

J. Perkins: The microstructure of rapidly solidified β-phase Cu-Zn-Al alloys. Metall. Trans. A 14(11), 2229 (1983).

S. Prashantha, M.K. Ranganatha Swamy, and U.S. Mallikarjun: Shape memory effect in Cu-Sn-Mn ternary shape memory alloy processed by ingot metallurgy. Int. J. Metall. Mater. Sci. Eng. (IJMMSE) 2(1), 12 (2012).

H.C. Yi and J.J. Moore: Self-propagating high-temperature (combustion) synthesis (SHS) of powder-compacted material. J. Mater. Sci. 25(2), 1159 (1990).

V. Asanovic, K. Delijicm, and N. Jaukovic: A study of transformations of β-phase in Cu–Zn–Al shape memory alloys. Scr. Mater. 58, 599 (2008).

Y. Sutou, T. Omori, R. Kainuma, and K. Ishida: Ductile Cu-Al-Mn based shape memory alloys: General properties and applications. Mater. Sci. Technol. 24(8), 896 (2008).

J. Ma, I. Karaman, and R.D. Noebe: High temperature shape memory alloys. Int. Mater. Rev. 55(5), 257 (2010).

F. Saule, M. Ahlers, F. Kropef, and E.B. Rivero: The martensitic phases and their stability in Cu-Zn and Cu-Zn-Al alloys—IV. The influence of lattice parameter changes and evaluation of phase stabilities. Acta Metall. 40(12), 3229 (1992).

C. Ling-fei, W. Ming-pu, L. Zhou, X. Ben, and S. Yu-chang: Thermal cycling effect in Cu-11.9Al-2.5Mn shape memory alloy with high Ms temperature. Trans. Nonferrous Soc. China 12(4), 716 (2002).

Y. Sutou, T. Omori, R. Kainuma, N. Ono, and K. Ishida: Enhancement of superelasticity in Cu-Al-Mn-Ni shape-memory alloys by texture control. Metall. Mater. Trans. A 33A(9), 2817 (2002).

Q. Wang, F. Han, C. Cui, S. Bu, and L. Bai: Effect of aging on the reverse martensitic phase transformation behaviours of Cu-Al-Mn shape memory alloys. Mater. Lett. 61, 5185 (2007).

J. Chen, Z. Lia, and Y.Y. Zhao: A high-working-temperature CuAlMnZr shape memory alloy. J. Alloys Compd. 480, 481 (2009).

F. Dagdelen, T. Gokhan, A. Aydogdu, Y. Aydogdu, and O. Adigüzel: Effects of thermal treatments on transformation behaviour in shape memory Cu-Al-Ni alloys. Mater. Lett. 57, 1079 (2003).

U. Sarı and T. Kirindi: Effects of deformation on microstructure and mechanical properties of a Cu-Al-Ni shape memory alloy. Mater. Charact. 59, 920 (2008).

M. Miki, N. Maeshiro, and Y. Ogino: Effects of additional elements on the super plasticity of a Cu-14Al-3Ni shape memory alloy. Mater. Trans., JIM 30(12), 999 (1989).

N. Shajil, D. Das, and L. Chandrasekaran: Effects of cycling on the pseudoelastic properties of CuAlMnNi & TiNi based pseudoelastic alloys. Int. J. Struct. Changes Solids–Mech. Appl. 1(1), 171 (2009).

Y. Chen, X. Zhang, D.C. Dunand, and C.A. Schuh: Shape memory and superelasticity in polycrystalline Cu–Al–Ni microwires. Appl. Phys. Lett. 95(17), 906 (2009).

Y. Sutou, N. Koeda, T. Omori, R. Kainuma, and K. Ishida: Effects of ageing on bainitic and thermally induced martensitic transformations in ductile Cu–Al–Mn-based shape memory alloys. Acta Mater. 57, 5748 (2009).

Y. Sutou, N. Koeda, T. Omori, R. Kainuma, and K. Ishida: Effect of aging on stress induced martensitic transformations in ductile Cu-Al-Mn based shape memory alloys. Acta Mater. 57, 5759 (2009).

S.K. Vajpai, R.K. Dube, and S. Sangal: Processing and characterization of Cu-Al-Ni shape memory alloy strips prepared from prealloyed powder by hot densification rolling of powder preforms. Metall. Mater. Trans. 42A, 3178 (2011).

R. Zengin and M. Ceylan: The effects of neutron irradiation on oxidation behavior, microstructure and transformation temperatures of Cu–12.7 wt.% Al–5 wt.% Ni–2 wt.% Mn shape memory alloy. Mater. Lett. 58, 55 (2003).

R. Zengin: Microstructure and oxidation properties of a neutron-irradiated Cu–13.5wt% Al–4 wt% Ni shape memory alloy. Phys. B 363, 110 (2005).

S. Stanciu, L-G. Bujoreanu, B. Özkal, M. Lutfi Öveçoğlu, and A.V. Sandu: Study of precipitate formation in Cu–Al–Ni–Mn–Fe shape memory alloys. J. Optoelectron. Adv. Mater. 10(6), 1365 (2008).

C. Xiaomin, H. Feng, L. Ni, and W. Xingwen: Microstructure and shape memory effect of Cu-26.1Zn-4.8Al alloy. J. Wuhan Univ. Technol., Mater. Sci. Ed. 23, 717 (2008).

V. Asanovic and K. Delujc: The mechanical behavior and shape memory recovery of Cu-Zn-Al alloys. Metalurgija 13(1), 59 (2007).

Y.J. Bai, G.L. Geng, X.F. Bian, D.S. Sun, and S.R. Wang: Influence of initial heating temperature on the reverse martensitic transformation of Cu–Zn–Al–Mn–Ni alloy. Mater. Sci. Eng., A 284, 25 (2000).

N. Kayali, S. Ozgen, and O. Adigiizel: The influence of ageing on martensite morphology in shape memory Cu–Zn–Al alloys. J. Phys. IV France 7(C5), 317 (1997).

V.H.C. de Albuquerque, T.A. de A. Melo, R.M. Gomes, S.J.G. de Limaa, and J.M.R.S. Tavares: Grain size and temperature influence on the toughness of a Cu-Al-Be shape memory alloy. Mater. Sci. Eng., A 528, 459 (2010).

P. Zhang, A. Ma, S. Lu, P. Lin, J. Jiang, H. Ma, and C. Chu: Effect of equal channel angular pressing and heat treatment on the microstructure of Cu-Al-Be-B shape memory alloy. Mater. Lett. 63, 2676 (2009).

S. Montecinos and A. Cuniberti: Martensitic transformation and grain size in a Cu-Al-Be alloy. Procedia Mater. Sci. 1, 149 (2012).

A. Abu Arab and M. Ahlers: The stabilization of martensite in Cu-Zn-Al alloys. Acta Metall. 36(9), 2627 (1988).

F. Saule and M. Ahlers: Stability, stabilization and lattice parameters in Cu-Zn-Al martensites. Acta Metall. Mater. 43(6), 2373 (1995).

N. Kuwano, T. Doi, and T. Eguchi: Annealing behaviour of heavily deformed martensites of Cu-Al alloys. Mater. Trans., JIM 20, 37 (1979).

S. Sathish, U.S. Mallik, and T.N. Raju: Microstructure and shape memory effect of Cu-Zn-Ni shape memory alloys. J. Miner. Mater. Charact. Eng. 2, 71 (2014).

S. Pourkhorshidi, N. Parvin, M.S. Kenevisi, M. Naeimi, and H. Ebrahimnia Khaniki: A study on the microstructure and properties of Cu-based shape memory alloy produced by hot extrusion of mechanically alloyed powders. Mater. Sci. Eng., A 556, 658 (2012).

J.M. Guilemany, F. Peregrín, F.C. Lovey, N. LLorca, and E. Cesari: TEM study of β and martensite in Cu-Al-Mn shape memory alloys. Mater. Charact. 26, 23 (1991).

E. Hornbogen, V. Mertinger, and J. Spielfield: Ausageing and ausforming of a copper based shape memory alloy with high transformation temperatures. Z. Metallkd. 90(5), 318 (1999).

O. Adigiizel: Martensite ordering and stabilization in copper based shape memory alloys. Mater. Res. Bull. 30(6), 755 (1995).

S.N. Sauda, E. Hamzaha, T. Abubakara, and R. Hosseinian: A review on influence of alloying elements on the microstructure and mechanical properties of Cu-Al-Ni shape memory alloys. Jurnal Reknologi (Sciences & Engineering) 64(1), 51 (2013).

H. Sakamoto, Y. Kijima, and K. Shimizu: Fatigue and fracture characteristics of polycrystalline Cu-Al-Ni shape memory alloys. Mater. Trans., JIM 23, 585 (1982).

S. Kustov, S. Golyandin, K. Sapozhnikov, E. Cesari, J. Van Humbeeck, and R. De Batist: Influence of martensitic stabilization on the low temperature non-linear anelasticity in Cu-Zn-Al shape memory alloys. Acta Mater. 50, 3023 (2002).

Y. Suotou, T. Omori, R. Kainuma, and K. Ishida: Ductile Cu-Al-Mn based shape memory alloys: General properties and applications. Mater. Sci. Technol. 24(8), 896 (2008).

U.S. Mallik and V. Sampath: Effect of alloying on microstructure and shape memory characteristics of Cu–Al–Mn shape memory alloys. Mater. Sci. Eng., A 481–482, 680 (2008).

C. Segui, E. Cesari, and J. Van Humbeeck: Irreversibility in two stage martensitic transformation of Cu-Al-Ni and Cu-Zn-Mn alloys. Mater. Trans., JIM 31(5), 375 (1990).

M. Sharma, S.K. Vajpai, and R.K. Dube: Processing and characterization of Cu-Al-Ni shape memory alloy strips prepared from elemental powders via a novel powder metallurgy route. Metall. Mater. Trans. A 41A, 2905 (2010).

Z. Li, Z.Y. Pan, N. Tang, Y.B. Jiang, N. Liu, M. Fang, and F. Zheng: Cu–Al–Ni–Mn shape memory alloy processed by mechanical alloying and powder metallurgy. Mater. Sci. Eng., A 417, 225 (2006).

U.S. Mallik and V. Sampath: Influence of quaternary alloying additions on transformation temperatures and shape memory properties of Cu–Al–Mn shape memory alloy. J. Alloys Compd. 469, 156 (2009).

V.R. Harchekar and M. Singla: Cu—Zn—Al (6%) shape memory alloy with low martensitic temperature and a process for its manufacture. Patent 7195681, Issued on March 27, 2007.

R. Zengin and M. Ceylan: The changes in transformation temperatures under stress of Cu-12.7Al-5Ni-2Mn alloys. Thermochim. Acta 414, 155 (2004).

A.C. Kneissl, E. Unterweger, and G. Lojen: Functional properties of wires and thin ribbons of several shape memory alloys. Adv. Eng. Mater. 8(11), 1113 (2006).

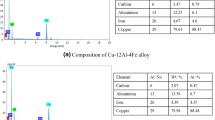

S. Yang, Y. Su, C. Wang, and X. Liu: Microstructure and properties of Cu–Al–Fe high-temperature shape memory alloys. Mater. Sci. Eng., B 185, 67 (2014).

Y. Sutou, T. Omori, K. Yamauchi, N. Ono, R. Kainuma, and K. Ishida: Effect of grain size and texture on pseudoelasticity in Cu–Al–Mn-based shape memory wire. Acta Mater. 53, 4121 (2005).

F.M. Sánchez-Arévalo, T. García-Fernández, G. Pulos, and M. Villagrán-Muniz: Use of digital speckle pattern correlation for strain measurements in a CuAlBe shape memory alloy. Mater. Charact. 60, 775–782 (2009).

Z. Xiao, M. Fang, Z. Li, T. Xiao, and Q. Lei: Structure and properties of ductile Cu-Al-Mn shape memory alloy synthesized by mechanical alloying and powder metallurgy. Mater. Des. 58, 451 (2014).

H. Funakubo: Shape Memory Alloys, 1st ed.; Gordon and Breach Science Publishers: New York, 1987; p. 226.

C.M. Wayman and T.W. Duerig: An introduction to martensite and shape memory. Engineering Aspects of Shape Memory Alloys, 1st ed.; Butterworth-Heinemann: Oxford, 1990; p. 3.

T.A. Schroeder and C.M. Wayman: The two-way shape memory effect and other “training” phenomena in Cu-Zn single crystals. Scr. Metall. 11(3), 225 (1977).

R. Stalmans, J. Van Humbeeck, and L. Delaey: Training and the two way memory effect in copper based shape memory alloys. J. Phys. IV C4(1), 403 (1991).

H. Wei Min: Two-way behavior of a Nitinol torsion bar. In Proc. SPIE Vol. 3675, Smart Structures and Materials; Smart Materials Technologies, M. Wuttig, ed. (SPIE Digital Library, Newport Beach, CA, 1999); p. 284.

J. San Juan, M.L. Nó, and C.A. Schuh: Superelastic cycling of Cu–Al–Ni shape memory alloy micropillars. Acta Mater. 60(10), 4093 (2012).

W. Huang and W. Toh: Training two-way shape memory alloy by reheat treatment. J. Mater. Sci. Lett. 19, 1549 (2000).

A.C. Kneisl, E. Unterweger, and G. Lojen: Functional properties of wires and thin ribbons of several shape memory alloys. Adv. Eng. Mater. 8(11), 1115 (2006).

Y. Bai, Q. Shi, G. Geng, D. Sun, and X. Bian: Formation mechanism of curved martensite structure in Cu based shape memory alloys. J. Mater. Sci. Technol. 16(1), 78 (2000).

R. Casati, M. Vedani, and A. Tuiss: Thermal cycling of stress-induced martensite for high-performance shape memory effect. Scr. Mater. 80, 13 (2014).

G.S. Firstov, J. Van Humbeeck, and Y.N. Koval: High temperature shape memory alloys: Problems and prospects. J. Intell. Mater. Syst. Struct. 17, 1041 (2006).

I. Hopulele, S. Istrate, S. Stanciu, and Gh. Calugaru: Comparative study of certain Cu-Zn-Al-type alloys concerning their superelastic behavior and shape memory. J. Optoelectronics Adv. Mater. 6(1), 277 (2004).

D. Hel: Pseudoelastic behavior of shape memory alloys: Constitutive theory and identification of the material parameters using neural network. Technische Mechanik 25(1), 39 (2005).

M.C. Van Schoor: Method and device for measuring strain using shape memory alloy materials, Issued patent: US6550341, Issue date April 22, 2003.

M.S. Alam, M.A. Youssef, and M. Nehdi: Utilizing shape memory alloys to enhance the performance and safety of civil infrastructure: A review. Can. J. Civ. Eng. 34(9), 1075 (2007).

B. Cunningham and K.H.G. Ashbee: An in situ SEM kossel x-ray diffraction study of pseudoelasticity. Acta Metall. Mater. 38(12), 2561 (1990).

S. Miura and H. Kato: Thermodynamical analysis of pseudoelasticity and calorimetry in shape memory alloys. Mater. Sci. Res. Int. 2, 67 (1995).

Z. Wei, J. Laizhu, L. Ning, and W. Yuhua: Improvement of shape memory effect in an Fe–Mn–Si–Cr–Ni alloy fabricated by equal channel angular pressing. J. Mater. Process Technol. 208(1–3), 130 (2008).

S. Montecinos, A. Cuniberti, and A. Sepúlveda: Grain size and pseudoelastic behaviour of a Cu–Al–Be alloy. Mater. Charact. 59, 117 (2008).

A. Yawny, J. Malarria, F.C. Lovey, and M. Sade: Recoverable effects related to pseudoelastic cycling in Cu-Zn-Al single crystals. J. Phys. C5, 531 (1997).

J. Van Humbeeck and L. Delaey: The influence of strain-rate, amplitude and temperature on the hysteresis of a pseudoelastic Cu-Zn-Al single crystal. J. Phys. C5, 1007 (1981).

S. Miyazaki, Y.Q. Fu, and W.M. Huang: Thin Film Shape Memory Alloys, 1st ed.; Cambridge University Press: Cambridge, England, 2009; pp. 261, 370.

J. San Juan, M.L. No, and C.A. Schuh: Thermomechanical behavior at the nanoscale and size effects in shape memory alloys. J. Mater. Res. 26(19), 2461 (2011).

H. Pops: Stress-induced pseudoelasticity in ternary Cu-Zn based beta prime phase alloys. Metall. Trans. 1(25), 1 (1970).

S. Casciati: Experimental studies on the fatigue life of shape memory alloy bars. Smart Struct. Syst. 6(1), 73 (2010).

J. Ortín and A. Planes: Thermodynamics of thermoelastic martensitic transformations. Acta Metall. 37(5), 1433 (1989).

M.A. Dvorack, N. Kuwano, S. Polat, H. Chen, and C.M. Wayman: Decomposition of a β1-phase Cu-Al-Ni alloy at elevated temperature. Scr. Metall. 17(11), 1333 (1983).

M.A. Morris: High temperature properties of ductile Cu-Al-Ni shape memory alloys with boron additions. Acta Metall. 40, 1573 (1992).

C.M. Wayman: Thennoelastic martensitic transformations and the shape memory effect. In Proc. of the Int. Conf. on phase Trans. In Soliak, Maleme-Chania, North-Holland, New York, 1984, p. 657.

J. Van Humbeeck: High temperature shape memory alloys. Trans. ASME 12, 98 (1999).

K. Marukawa and K. Tsuchiya: Two important aging effects on the martensite phase in CuZnAI alloys: Rubber effect and stabilization of martensite. J. Phys. 11, 8 (2001).

D. Junkai, D. Xiangdong, L. Turab, S. Tetsuro, O. Kazuhiro, S. Jun, A. Saxena, and R. Xiaobing: Microscopic mechanism of martensitic stabilization in shape-memory alloys: Atomic-level processes. Phys. Rev. B 81(22), 1 (2010).

Y. Wang, X. Ren, and K. Otsuka: Shape memory effect and superelasticity in a strain glass alloy. Phys. Rev. Lett. 97(22), 5703 (2006).

R. Romero and M. Stipcich: The stabilization of martensite in Cu-Zn-Al-Ti-B shape memory alloys. Fifth European symposium on martensitic transformations and shape memory alloys. J. Phys. 11(8), 135 (2001).

B.M. Rabeeh, M.M. El Batanouny, and A.E. El Ashram: Microstructural characterization and solid state processing of Cu-Zn-Al shape memory alloy. Can. J. Mech. Sci. Eng. 2(2), 11 (2011).

L. Janke, C. Czaderski, M. Motavalli, and J. Ruth: Application of shape memory alloys in civil engineering structures–Overview, limits and new ideas. Mater. Struct. RILEM 38(279), 578 (2005).

M.G. Rashed: Civil engineering application of shape memory alloys. In Proceedings of 1st International Conference on Advances in Civil Engineering, CUET, Chittagong, Bangladesh, 2012; p. 1.

Y. Sutou, T. Omoria, J.J. Wang, R. Kainuma, and K. Ishida: Characteristics of Cu–Al–Mn-based shape memory alloys and their applications. Mater. Sci. Eng., A 378, 278 (2004).

S.R. Debbarma and S. Saha: Review of shape memory alloys applications in civil structures, and analysis for its potential as reinforcement in concrete flexural members. Int. J. Civ. Struct. Eng. 2(3), 924 (2012).

J. Sepúlveda, R. Boroschek, R. Herrera, O. Moroni, and M. Sarrazin: Steel beam–column connection using copper-based shape memory alloy dampers. J. Constr. Steel Res. 64(4), 429 (2008).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dasgupta, R. A look into Cu-based shape memory alloys: Present scenario and future prospects. Journal of Materials Research 29, 1681–1698 (2014). https://doi.org/10.1557/jmr.2014.189

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2014.189