Abstract

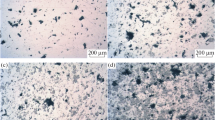

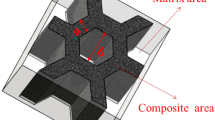

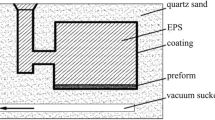

Tungsten carbide (WC) particle–reinforced iron matrix surface composites with different content of Cr were fabricated using vacuum evaporative pattern casting technique. It was found that the morphology of carbides changed from continuous net-shape to isolated block-shape patterns. The amount of carbides increase with the increasing Cr content in the matrices. Composites with different Cr content show better abrasive wear resistance than those without Cr. With the increase of Cr content in the matrices, the three-body abrasive wear resistance of the composites increased, while the impact abrasive wear resistance of the composites increased under 1 J impact load, but first increased and then decreased under 3 J impact load. The influences of the addition of Cr in the matrices on the abrasive wear resistance were the synergistic effects of two protecting effects and two supporting effects. The results might provide significant references for the design and practical application of WC particle–reinforced iron matrix surface composites.

Similar content being viewed by others

REFERENCES

T.M. Cornsweet: Advanced composite materials. Science 168 (3930), 433 (1970).

J.W. Qiao, T. Zhang, F.Q. Yang, P.K. Liaw, S. Pauly, and B.S. Xu: A tensile deformation model for in-situ dendrite/metallic glass matrix composites. Sci. Rep. 3, 02816 (2013).

Q.L. Dai, B.B. Sun, M.L. Sui, G. He, Y. Li, J. Eckert, W.K. Luo, and E. Ma: High-performance bulk Ti-Cu-Ni-Sn-Ta nanocomposites based on a dendrite-eutectic microstructure. J. Mater. Res. 19 (09), 2557 (2004).

J. Eckert, J. Das, S. Pauly, and C. Duhamel: Mechanical properties of bulk metallic glasses and composites. J. Mater. Res. 22 (02), 285 (2007).

G. He, W. Loser, J. Eckert, and L. Schultz: Enhanced plasticity in a Ti-based bulk metallic glass-forming alloy by in situ formation of a composite microstructure. J. Mater. Res. 17 (12), 3015 (2002).

X.F. Pan, H. Zhang, Z.F. Zhang, M. Stoica, G. He, and J. Eckert: Vickers hardness and compressive properties of bulk metallic glasses and nanostructure-dendrite composites. J. Mater. Res. 20 (10), 2632 (2005).

F.F. Wu, Z.F. Zhang, A. Peker, S.X. Mao, J. Das, and J. Eckert: Strength asymmetry of ductile dendrites reinforced Zr- and Ti-based composites. J. Mater. Res. 21 (09), 2331 (2006).

Y. Bai, J. Xing, Z. Liu, S. Ma, E. Liu, and Y. Gao: The microstructure and tribological property of in-situ Al2O3/Fe–25Al composites in argon atmosphere. Intermetallics 38, 107 (2013).

Y. Bai, J. Xing, S. Ma, Q. Huang, Y. He, Z. Liu, and Y. Gao: Effect of 4 wt.% Cr on microstructure, corrosion resistance and tribological properties of Fe3Al–20wt.%Al2O3 composites. Mater. Charact. 78, 69 (2013).

Y. Bai, J. Xing, H. Wu, Z. Liu, Y. Gao, and S. Ma: Study on preparation and mechanical properties of Fe3Al–20wt.%Al2O3 composites. Mater. Des. 39, 211 (2012).

Y. Bai, J. Xing, H. Wu, Z. Liu, Q. Huang, S. Ma, and Y. Gao: The mechanical alloying mechanism of various Fe2O3–Al–Fe systems. Adv. Powder Technol. 24 (1), 373 (2013).

G. He, J. Eckert, W. Loser, and L. Schultz: Novel Ti-base nanostructure-dendrite composite with enhanced plasticity. Nat. Mater. 2 (1), 33 (2003).

G.N. Greaves, A.L. Greer, R.S. Lakes, and T. Rouxel: Poisson’s ratio and modern materials. Nat. Mater. 10 (11), 823 (2011).

S. Pauly, S. Gorantla, G. Wang, U. Kühn, and J. Eckert: Transformation-mediated ductility in CuZr-based bulk metallic glasses. Nat. Mater. 9 (6), 473 (2010).

D.C. Hofmann, J.Y. Suh, A. Wiest, G. Duan, M.L. Lind, M.D. Demetriou, and W.L. Johnson: Designing metallic glass matrix composites with high toughness and tensile ductility. Nature 451 (7182), 1085 (2008).

E. Pagounis, M. Talvitie, and V. Lindroos: Influence of the metal/ceramic interface on the microstructure and mechanical properties of HIPed iron-based composites. Compos. Sci. Technol. 56 (11), 1329 (1996).

E. Pagounis and V.K. Lindroos: Processing and properties of particulate reinforced steel matrix composites. Mater. Sci. Eng., A 246 (1–2), 221 (1998).

I.A. Ibrahim, F.A. Mohamed, and E.J. Lavernia: Particulate reinforced metal matrix composites—a review. J. Mater. Sci. 26 (5), 1137 (1991).

M.N. Yuan, Y.Q. Yang, C. Li, P.Y. Heng, and L.Z. Li: Numerical analysis of the stress–strain distributions in the particle reinforced metal matrix composite SiC/6064Al. Mater. Des. 38 (0), 1 (2012).

S.J. Guo, G.Z. Kang, and J. Zhang: A cyclic visco-plastic constitutive model for time-dependent ratchetting of particle-reinforced metal matrix composites. Int. J. Plast. 40 (0), 101 (2013).

R. Zhou, Y. Jiang, and D. Lu: The effect of volume fraction of WC particles on erosion resistance of WC reinforced iron matrix surface composites. Wear 255 (1–6), 134 (2003).

D. Lou, J. Hellman, D. Luhulima, J. Liimatainen, and V.K. Lindroos: Interactions between tungsten carbide (WC) particulates and metal matrix in WC-reinforced composites. Mater. Sci. Eng., A 340 (1–2), 155 (2003).

D.J. Liu, L.Q. Li, F.Q. Li, and Y.B. Chen: WCp/Fe metal matrix composites produced by laser melt injection. Surf. Coat. Technol. 202 (9), 1771 (2008).

Z.L. Li, Y.H. Jiang, R. Zhou, D.H. Lu, and R.F. Zhou: Dry three-body abrasive wear behavior of WC reinforced iron matrix surface composites produced by V-EPC infiltration casting process. Wear 262 (5–6), 649 (2007).

J.N. Li, C.Z. Chen, C.F. Zhang, and W. Li: Improvement in surface performance of Al3Ti+ TiB2/(Ni coated WC) laser cladded coating with Al2O3/nano-Y2O3. Mater. Res. Innovations 15 (5), 344 (2011).

S.W. Huang, M. Samandi, and M. Brandt: Abrasive wear performance and microstructure of laser clad WC/Ni layers. Wear 256 (11–12), 1095 (2004).

R.O. Ritchie: The conflicts between strength and toughness. Nat. Mater. 10 (11), 817 (2011).

T. Sornakumar, M. Kathiresan, and A. Senthilkumar: Drilling of die cast aluminium alloy–aluminium oxide composites. Mater. Res. Innovations 14 (4), 293 (2010).

M. Kök: Prediction and optimisation of abrasive wear model for particle reinforced MMCs using statistical analysis. Mater. Res. Innovations 15 (5), 366 (2011).

B-S. Kim, T. Sekino, T. Nakayama, M. Wada, J-S. Lee, and K. Niihara: Pulse electric current sintering of alumina/nickel nanocomposites. Mater. Res. Innovations 7 (2), 57 (2003).

W. Chen, Y. Gao, C. Chen, and J. Xing: Tribological characteristics of Si3N4–hBN ceramic materials sliding against stainless steel without lubrication. Wear 269 (3–4), 241 (2010).

S. Ma, J. Xing, D. Yi, H. Fu, J. Zhang, Y. Li, Z. Zhang, G. Liu, and B. Zhu: Effects of chromium addition on corrosion resistance of Fe–3.5B alloy in liquid zinc. Surf. Coat. Technol. 205 (21–22), 4902 (2011).

H. Yang and R. Luo: Effect of coal tar pitch modified by sulfur as a binder on the mechanical and tribological properties of bronze-impregnated carbon-matrix composites. Mater. Sci. Eng., A 528 (6), 2929 (2011).

ACKNOWLEDGMENT

The authors acknowledge the funding support from the National Science Foundation of China (51241002, 51361019).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Z., Jiang, Y., Zhou, R. et al. Effect of Cr addition on the microstructure and abrasive wear resistance of WC-reinforced iron matrix surface composites. Journal of Materials Research 29, 778–785 (2014). https://doi.org/10.1557/jmr.2014.38

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2014.38