Abstract

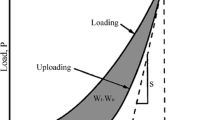

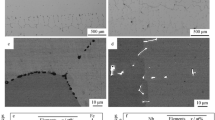

The effects of Fe2B-grain orientation on microstructure and properties of bulk Fe2B intermetallic fabricated by directional and ordinary solidification techniques have been investigated. The results show that unidirectional solidified Fe2B intermetallic possesses a strong (002) texture in the transverse direction owing to the opposite unidirectional heat-squeeze effect while random Fe2B grains can be produced under ordinary solidification conditions. The nonoriented Fe2B intermetallic has the highest linear expansion coefficient of 13.04 × 10−6 °C−1 while the microhardness and fracture toughness of transverse Fe2B intermetallic in the (002) plane are larger than those of Fe2B with other grain orientations and their values are ∼18.72 GPa and 6.42 MPa·m1/2, respectively. Liquid zinc corrosion results indicate that unidirectional Fe2B intermetallic with long axis perpendicular to the direction of liquid zinc corrosion displays the best corrosion resistance to liquid zinc owing to its beneficial barrier effect. The FeB transition phase can naturally form and grow parabolically during liquid zinc corrosion.

Similar content being viewed by others

References

V.I. Dybkov, W. Lengauer, and K. Barmak: Formation of boride layers at the Fe-10%Cr alloy-boron interface. J. Alloys Compd. 398, 113 (2005).

Z. Hu, Y. Fan, Y. Wu, Q. Yan, and Y. Chen: Crystallization and structure of high boron content iron-boron ultrafine amorphous alloy particles. J. Mater. Sci. 31, 611 (1996).

O. Ozdemir, M. Usta, C. Bindal, and A. Ucisik: Hard iron boride (Fe2B) on 99.97wt% pure iron. Vacuum 80, 1391 (2006).

U. Sen, S. Sen, S. Koksal, and F. Yilmaz: Fracture toughness of borides formed on boronized ductile iron. Mater. Des. 26, 175 (2005).

S. Taktak: Some mechanical properties of borided AISI H13 and 304 steels. Mater. Des. 28, 1836 (2007).

Y. Kayali, S. Taktak, S. Ulu, and Y. Yalcin: Investigation of mechanical properties of boro-tempered ductile iron. Mater. Des. 31, 1799 (2010).

D.N. Tsipas, G.K. Triantafyllidis, K.J. Kiplagat, and P. Psillaki: Degradation behaviour of boronized carbon and high alloy steels in molten aluminium and zinc. Mater. Lett. 37, 128 (1998).

S.Q. Ma, J.D. Xing, H.G. Fu, D.W. Yi, X.H. Zhi, and Y.F. Li: Effects of boron concentration on the corrosion resistance of Fe-B alloys immersed in 460 °C molten zinc bath. Surf. Coat. Technol. 204, 2208 (2010).

S.Q. Ma, J.D. Xing, D.W. Yi, H.G. Fu, J.J. Zhang, Y.F. Li, Z.Y. Zhang, G.F. Liu, and B.J. Zhu: Interfacial morphology and corrosion resistance of Fe-B cast steel containing chromium and nickel in liquid zinc. Corros. Sci. 53, 2826 (2011).

S.Q. Ma, J.D. Xing, D.W. Yi, H.G. Fu, J.J. Zhang, Y.F. Li, Z.Y. Zhang, G.F. Liu, and B.J. Zhu: Microstructure and corrosion behavior of cast Fe-B alloys dipped into liquid zinc bath. Mater. Charact. 61, 866 (2010).

D.N. Tsipas and J. Rus: Boronizing of alloy steels. J. Mater. Sci. Lett. 6, 118 (1987).

D.W. Yi, J.D. Xing, S.Q. Ma, H.G. Fu, Y.F. Li, W. Chen, J.B. Yan, J.J. Zhang, and R.R. Zhang: Investigations on microstructures and two-body abrasive wear behavior of Fe-B cast alloy. Tribol. Lett. 45, 427 (2012).

Z.F. Huang, J.D. Xing, and C. Guo: Improving fracture toughness and hardness of Fe2B in high boron white cast iron by chromium addition. Mater. Des. 31, 3084 (2010).

J.J. Coronado: Effect of (Fe,Cr)7C3 carbide orientation on abrasion wear resistance and fracture toughness. Wear 270, 287 (2011).

Ö.N. Doğan and J.A. Hawk: Effect of carbide orientation on abrasion of high Cr white cast iron. Wear 189, 136 (1995).

S.R. Wang, L.H. Song, Y. Qiao, and M. Wang: Effect of carbide orientation on impact-abrasive wear resistance of high-Cr iron used in shot blast machine. Tribol. Lett. 50, 439 (2013).

L. Sun, Y.M. Gao, B. Xiao, Y.F. Li, and G.L. Wang: Anisotropic elastic and thermal properties of titanium borides by first-principles calculations. J. Alloys Compd. 579, 457 (2013).

F.C. Yin, X.L. Ruan, M.X. Zhao, Y.X. Liu, and Z. Li: The 600 °C and 450 °C isothermal sections of the Zn-Fe-B system. J. Alloys Compd. 565, 79 (2013).

Z.F. Huang, S.Q. Ma, J.D. Xing, and B.Y. Wang: Bulk Fe2B crystal fabricated by mechanical ball milling and plasma activated sintering. J. Alloys Compd. 582, 196 (2014).

W.C. Liu, L.K. Jiang, L. Cao, J. Mei, G.H. Wu, S. Zhang, L. Xiao, S.H. Wang, and W.J. Ding: Fatigue behavior and plane-strain fracture toughness of sand-cast Mg-10Gd-3Y-0.5Zr magnesium alloy. Mater. Des. 59, 466 (2014).

W.J. Wang, J.P. Lin, Y.L. Wang, and G.L. Chen: The corrosion of Fe3Al alloy in liquid zinc. Corros. Sci. 1340 (2007).

S.Q. Ma, J.D. Xing, H.G. Fu, Y.L. He, Y. Bai, Y.F. Li, and Y.P. Bai: Interface characteristics and corrosion behaviour of oriented bulk Fe2B alloy in liquid zinc. Corros. Sci. 78, 71 (2014).

V. Raghavan: B-Fe-Si (boron-iron-silicon). J. Phase Equilib. Diffus. 28, 380 (2007).

B. Aronsson and I. Engström: X-ray investigations on Me-Si-B systems (Me=Mn, Fe, Co). II. Some features of the Fe-Si-B and Mn-Si-B systems. Acta Chem. Scand. 14, 1403 (1960).

Y. Li and R.P.H. Chang: Synthesis and characterization of iron silicon boron (Fe5Si2B) and iron boride (Fe3B) nanowires. J. Am. Chem. Soc. 128, 12778 (2006).

M.S. Li, S.L. Fu, W.D. Xu, R.L. Zhang, and R.H. Yu: Valence electron structure of Fe2B phase and its eigen-brittleness. Acta Metall. Sin. 31, 201 (1995).

B. Xiao, J.D. Xing, S.F. Ding, and W. Su: Stability, electronic and mechanical properties of Fe2B. Phys. B 403, 1723 (2008).

A. Van de Walle and G. Ceder: The effect of lattice vibrations on substitutional alloy thermodynamics. Rev. Mod. Phys. 74, 11 (2002).

A.A. Quong and A.Y. Liu: First-principles calculations of the thermal expansion of metals. Phys. Rev. B 56, 7767 (1997).

E. Hernández-Sanchez, G. Rodriguez, A. Meneses-Amador, D. Bravo-Bárcenas, I. Arzate-Vazquez, H. Martínez-Gutiérrez, M. Romero-Romo, and I. Campos-Silva: Effect of the anisotropic growth on the fracture toughness measurements obtained in the Fe2B layer. Surf. Coat. Technol. 237, 292 (2013).

C.Q. Guo: Modeling of spatial distribution of the eutectic M2B borides in Fe-Cr-B cast irons. J. Mater. Sci. 39, 1109 (2004).

S.Q. Ma, J.D. Xing, G.F. Liu, D.W. Yi, H.G. Fu, J.J. Zhang, and Y.F. Li: Effect of chromium concentration on microstructure and properties of Fe-3.5B alloy. Mater. Sci. Eng., A 527, 6800 (2010).

W.J. Wang, J.P. Lin, Y.L. Wang, and G.L. Chen: The corrosion of intermetallic alloys in liquid zinc. J. Alloys Compd. 428, 237 (2007).

A.R. Marder: The metallurgy of zinc-coated steel. Prog. Mater. Sci. 45, 191 (2000).

V.I. Dybkov and O.V. Duchenko: Growth kinetics of compound layers at the nickel-bismuth interface. J. Alloys Compd. 234, 295 (1996).

ACKNOWLEDGMENTS

The authors thank the financial support for this work from the Natural Science Foundation of China under Grant Nos. 51271142, 51301128, & 51274016, the Specialized Research Fund for the Doctoral Program of Higher Education of China under Grant Nos. 20110201130008 & 20120201120005, the National Science Foundation for Post-doctoral Scientists of China under Grant Nos. 2012M521767 & 2013T60875, the Natural Science Foundation of Shaanxi Province under Grant No. 2014JQ7281, the Shaanxi provincial post-doctoral research project, and the Fundamental Research Funds of Xi’an Jiaotong University under Grant Nos. xjj2013038 & xjj2014167.

Author information

Authors and Affiliations

Corresponding author

Additional information

Contributing Editor: Jürgen Eckert

Rights and permissions

About this article

Cite this article

Ma, S., Huang, Z., Xing, J. et al. Effect of crystal orientation on microstructure and properties of bulk Fe2B intermetallic. Journal of Materials Research 30, 257–265 (2015). https://doi.org/10.1557/jmr.2014.383

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2014.383