Abstract

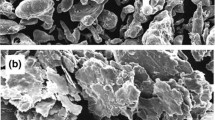

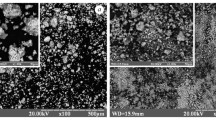

Isothermal annealing in the temperature range of 300–600 °C, microstructural characterization, and analysis of the grain growth kinetics during annealing were carried out for Cu–5 vol% Al2O3 nanocomposite powder particles produced by high energy mechanical milling. When the annealing temperature was 400 °C or lower, only reduction in dislocation density occurred during annealing. When the annealing temperature was 500 °C or higher, reduction in dislocation density, abnormal grain growth of the nanocrystalline Cu matrix, and coarsening of the Al2O3 nanoparticles occurred. It has been found that the microstructure of the nanocrystalline Cu matrix of the nanocomposite exhibits a far higher thermal stability than that of monolithic nanocrystalline Cu, even though the apparent activation energy of the grain growth of the former is similar to that of the latter over the temperature range of 400–600 °C, showing the dramatic drag effects of finely distributed Al2O3 nanoparticles and Al3+/O2− clusters on the grain boundary motion.

Similar content being viewed by others

References

B.Q. Han, J. Ye, A.P. Newbery, Y.T. Zhu, J.M. Schoenung, and E.J. Lavernia: In Bulk Nanostructured Materials, M.J. Zehetbauer and Y.T. Zhu ed.; Wiley-VCH Verlag: Weinheim, 2009; p. 273.

D.L. Zhang, S. Raynova, C.C Koch, R.O. Scattergood, and K.M. Youssef: Consolidation of a Cu-2.5 vol.% Al2O3 powder using high energy mechanical milling. Mater. Sci. Eng., A 410, 375 (2005).

S. Cheng, E. Ma, Y.M Wang, L.J. Kecskes, K.M. Youssef, C.C. Koch, U.P Trociewitz, and K. Han: Tensile properties of in situ consolidated nanocrystalline Cu. Acta Mater. 53(5), 1521 (2005).

L. He and E. Ma: Processing and microhardness of bulk Cu-Fe nanocomposites. Nanostruct. Mater. 7(3), 327 (1996).

C. Langlois, M.J. Hytch, S. Lartigue-Korinek, Y. Champion, and P. Langlois: Synthesis and microstructure of bulk nanocrystalline copper. Metall. Mater. Trans. A 36(12), 3451 (2005).

M. Pozuelo, C. Melnyk, W.H. Kao, and J-M. Yang: Cryomilling and spark plasma sintering of nanocrystalline magnesium-based alloy. J. Mater. Res. 26(07), 904 (2011).

C.C. Koch, R.O. Scattergood, K.A. Darling, and J.E. Semones: Stabilization of nanocrystalline grain sizes by solute additions. J. Mater. Sci. 43(23), 7264 (2008).

J. Weissmüller: Alloy effects in nanostructures. Nanostruct. Mater. 3(1), 261 (1993).

B.K. VanLeeuwen, K.A. Darling, C.C. Koch, R.O. Scattergood, and B.G. Butler: Thermal stability of nanocrystalline Pd81Zr19. Acta Mater. 58(12), 4292 (2010).

C.E. Krill, H. Ehrhardt, and R. Birringer: Thermodynamic stabilization of nanocrystallinity. Z. Metallkd. 96(10), 1134 (2005).

K.A. Darling, B.K. VanLeeuwen, C.C. Koch, and R.O. Scattergood: Thermal stability of nanocrystalline Fe–Zr alloys. Mater. Sci. Eng., A 527(15), 3572 (2010).

M.A. Atwater, R.O. Scattergood, and C.C. Koch: The stabilization of nanocrystalline copper by zirconium. Mater. Sci. Eng., A 559, 250 (2013).

T.R. Malow and C.C. Koch: Grain growth in nanocrystalline iron prepared by mechanical attrition. Acta Mater. 45(5), 2177 (1997).

K.W. Liu and F. Mücklich: Thermal stability of nano-RuAl produced by mechanical alloying. Acta Mater. 49(3), 395 (2001).

T. Chookajorn, H.A. Murdoch, and C.A. Schuh: Design of stable nanocrystalline alloys. Science 337(6097), 951 (2012).

X. Zhang, N.Q. Vo, P. Bellon, and R.S. Averback: Microstructural stability of nanostructured Cu–Nb–W alloys during high-temperature annealing and irradiation. Acta Mater. 59(13), 5332 (2011).

L. Shaw, H. Luo, J. Villegas, and D. Miracle: Thermal stability of nanostructured Al93Fe3Cr2Ti2 alloys prepared via mechanical alloying. Acta Mater. 51(9), 2647 (2003).

R.J. Perez, B. Huang, and E.J. Lavernia: Thermal stability of nanocrystalline Fe-10 wt.% Al produced by cryogenic mechanical alloying. Nanostruct. Mater. 7(5), 565 (1996).

D.G. Morris and M.A. Morris: Microstructure and strength of nanocrystalline copper alloy prepared by mechanical alloying. Acta Metall. 39(8), 1763 (1991).

B. Huang, R.J. Perez, and E.J. Lavernia: Grain growth of nanocrystalline Fe–Al alloys produced by cryomilling in liquid argon and nitrogen. Mater. Sci. Eng., A 255(1), 124 (1998).

L. Hashemi-Sadraei, S.E. Mousavi, R. Vogt, Y. Li, Z. Zhang, E.J. Lavernia, and J.M. Schoenung: Influence of nitrogen content on thermal stability and grain growth kinetics of cryomilled Al nanocomposites. Metall. Mater. Trans. A 43(2), 747 (2012).

E. Botcharova, J. Freudenberger, and L. Schultz: Mechanical and electrical properties of mechanically alloyed nanocrystalline Cu–Nb alloys. Acta Mater. 54(12), 3333 (2006).

J.I. Langford and A.J.C. Wilson: Scherrer after sixty years: a survey and some new results in the determination of crystallite size. J. Appl. Crystallogr. 11(2), 102 (1978).

U. Holzwarth and N. Gibson: The Scherrer equation versus the “Debye-Scherrer equation”. Nat. Nanotech. 6(9), 534 (2011).

A.R. Stokes and A.J.C. Wilson: The diffraction of X rays by distorted crystal aggregates-I. Proc. Phys. Soc. 56(3), 174 (1944).

G.K. Williamson and R.E. Smallman, III. Dislocation densities in some annealed and cold-worked metals from measurements on the x-ray debye-scherrer spectrum. Philos. Mag. 1(1), 34 (1956).

Y.H. Zhao, K. Lu, and K. Zhang: Microstructure evolution and thermal properties in nanocrystalline Cu during mechanical attrition. Phys. Rev. B 66(8), 085404 (2002).

S. Ni, Y.B. Wang, X.Z. Liao, S.N. Alhajeri, H.Q. Li, Y.H. Zhao, E.J. Lavernia, S.P. Ringer, T.G. Langdon, and Y.T. Zhu: Grain growth and dislocation density evolution in a nanocrystalline Ni–Fe alloy induced by high-pressure torsion. Scripta Mater. 64(4), 327 (2011).

J. Čížek, I. Procházka, M. Cieslar, R. Kužel, Z. Matěj, V. Cherkaska, R.K. Islamgaliev, and O. Kulyasova: Influence of ceramic nanoparticles on grain growth in ultra fine grained copper prepared by high pressure torsion. Phys. Status Solidi C 4(10), 3587 (2007).

J. Ďurišin, K. Ďurišinová, M. Orolínová, and K. Saksl: Effect of the MgO particles on the nanocrystalline copper grain stability. Mater. Lett. 58(29), 3796 (2004).

J.E. Burke: Some factors affecting the rate of grain growth in metals. Trans. Metall. Soc. AIME 180, 73 (1949).

H.V. Atkinson: Overview no. 65: Theories of normal grain growth in pure single phase systems. Acta Metall. 36(3), 469 (1988).

F. Zhou, J. Lee, and E.J. Lavernia: Grain growth kinetics of a mechanically milled nanocrystalline Al. Scripta Mater. 44(8–9), 2013 (2001).

A. Michels, C.E. Krill, H. Ehrhardt, R. Birringer, and D.T. Wu: Modelling the influence of grain-size-dependent solute drag on the kinetics of grain growth in nanocrystalline materials. Acta Mater. 47(7), 2143 (1999).

L. Lu, N.R. Tao, L.B. Wang, B.Z. Ding, and K. Lu: Grain growth and strain release in nanocrystalline copper. J. Appl. Phys. 89(11), 6408 (2001).

G. Gottstein, L.S. Shvindlerman, and B. Zhao: Thermodynamics and kinetics of grain boundary triple junctions in metals: Recent developments. Scripta Mater. 62(12), 914 (2010).

L.S. Shvindlerman and G. Gottstein: Efficiency of drag mechanisms for inhibition of grain growth in nanocrystalline materials. Z. Metallkd. 95(4), 239 (2004).

F.J. Humphreys and M. Hatherly: Recrystallization and Related Annealing Phenomena, 2nd ed.; Elsevier Science Ltd.: Oxford, UK, 2004; pp. 200–244.

S. Simões, R. Calinas, M.T. Vieira, M.F. Vieira, and P.J. Ferreira: In situ TEM study of grain growth in nanocrystalline copper thin films. Nanotechology 21(14), 145701 (2010).

J. Horvath, R. Birringer, and H. Gleiter: Diffusion in nanocrystalline material. Solid State Commun. 62(5), 319 (1987).

S.K. Ganapathi, D.M. Owen, and A.H. Chokshi: The kinetics of grain growth in nanocrystalline copper. Scripta Metall. 25(12), 2699 (1991).

W. Dickenscheid, R. Birringer, H. Gleiter, O. Kanert, B. Michel, and B. Günther: Investigation of self-diffusion in nanocrystalline copper by NMR. Solid State Commun. 79(8), 683 (1991).

Z.H. Cao, F. Wang, L. Wang, and X.K. Meng: Coupling effect of the electric and temperature fields on the growth of nanocrystalline copper films. Phys. Rev. B 81(11), 113405 (2010).

H. Mehrer: Diffusion in Solids: Fundamentals, Methods, Materials, Diffusion-Controlled Processes, 1st ed.; Springer-Verlag: Berlin, 2007; pp. 304.

C.S. Smith: Grains, phases, and interfaces: as interpretation of microstructure. Met. Technol. 15(4), 1 (1948).

J. Čížek, I. Procházka, R. Kužel, and R. Islamgaliev: In Nanostructured Materials, H. Hofmann, Z. Rahman, and U. Schubert eds.; Springer: Vienna, 2002; p. 137.

ACKNOWLEDGMENTS

The funding from the China Scholarship Council (CSC), National Natural Science Foundation of China (Project No. 51271115), Ministry of Science and Technology, China (Project No. 2012CB619600), and Ministry of Business, Innovation and Employment, New Zealand (Contract No. UOWX1001) to support this work is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, D., Zhang, D., Kong, C. et al. Thermal stability of the nanostructure of mechanically milled Cu–5 vol% Al2O3 nanocomposite powder particles. Journal of Materials Research 29, 996–1005 (2014). https://doi.org/10.1557/jmr.2014.79

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2014.79