Abstract

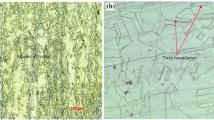

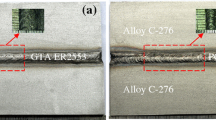

The present study investigates the joining of 5-mm-thick plates of superaustenitic stainless steel, AISI 904L by continuous current (CC) and pulsed current (PC) gas tungsten arc welding (GTAW) using ER2553 and ERNiCrMo-4 fillers. This research article attempts to provide a detailed structure–property relationship of these weldments. Interface microstructure revealed the absence of deleterious secondary phases at the heat affected zone in all the cases. Skeletal delta ferrite morphology at the cap of ER2553 fusion zone and multidirectional grain growth at the ERNiCrMo-4 fusion zone were observed for both the weldments. The average hardness at the fusion zone was found to be higher for PCGTA weldments using ER2553 due to the higher proportions of ferrite. Tensile studies corroborated that the failure occurred at the parent metal in all the cases. Charpy V-notch studies divulged that the CCGTA and PCGTA weldments utilizing ERNiCrMo-4 filler exhibited the greater impact toughness of 69 J and 75 J, respectively. The bend test results conveyed that both the CCGTA and PCGTA weldments using ERNiCrMo-4 exhibited soundness and ductility.

Similar content being viewed by others

REFERENCES

J.N. Dupont, S.W. Banovic, and A.R. Marder: Microstructural evolution and weldability of dissimilar welds between a super austenitic stainless steel and nickel-based alloys. Weld. J. 82, 125s–155s (2003).

H. Kuhn and D. Medlin, eds. ASM Handbook on Welding, Brazing and Soldering, Vol. 6 (ASM International, Ohio, 2010).

S. Nagarajan and N. Rajendran: Crevice corrosion behaviour of superaustenitic stainless steels: Dynamic electrochemical impedance spectroscopy and atomic force microscopy studies. Corros. Sci. 51, 217 (2009).

S. Hertzman, R. Jargelius Pettersson, R. Blom, E. Kivineva, and J. Eriksson: Influence of shielding gas composition and welding parameters on the N-content and corrosion properties of welds in N- alloyed stainless steel grades. ISIJ Int. 36 (7), 968–976 (1996).

I. Woo and Y. Kikuchi. Weldability of high nitrogen stainless steel. ISIJ Int. 42 (12), 1334–1343 (2002).

T. Koutsoukis, A. Redjaımia, and G. Fourlaris: Phase transformations and mechanical properties in heat treated super austenitic stainless steels. Mater. Sci. Eng., A 561, 477–485, (2013).

P. Sathiya, S. Aravindan, P.M. Ajith, B. Arivazhagan, and A. Noorul Haq: Microstructural characteristics on bead on plate welding of AISI 904 L super austenitic stainless steel using gas metal arc welding process. Int. J. Eng. Sci. Technol. 2 (6), 189–199 (2010).

K. Balamurugan, M. Kumar Mishra, P. Sathiya, A. Naveen Sait: Weldability studies, and parameter optimization of AISI 904L super austenitic stainless steel using friction welding. Mater. Res. 17 (4), 908–919 (2014).

P. Sathiya and M.Y. AbdulJaleel: Measurement of the bead profile and microstructural characterization of a CO2 laser welded AISI 904L super-austenitic stainless steel. Opt. Laser Technol. 42, 960–968 (2010).

S.W. Banovic, J.N. DuPont, and A.R. Marder: Dilution control in gas-tungsten-arc welds involving superaustenitic stainless steels and nickel-based alloys. Metall. Mater. Trans. B 32B, 1171–1176 (2001).

J.C. Lippold and D.J. Koteki: Welding Metallurgy and Weldability of Stainless Steels (John Wiley & Sons Inc., Hoboken, NJ, 2005).

A. Zambon, P. Ferro, and F. Bonollo: Microstructural, compositional and residual stress evaluation of CO2 laser welded super-austenitic AISI 904L stainless steel. Mater. Sci. Eng., A 424, 117–127 (2006).

S. Kumar and A.S. Shahi: Effect of heat input on the microstructure and mechanical properties of gas tungsten arc welded AISI 304 stainless steel joints. Mater. Des. 32, 3617–3623 (2011).

K. Manikanta Sriram, R. Hayagreev, V. Ajay Shri Bhuvanesh, Ajari Babaseaheb Abhishek, K. Devendranath Ramkumar, N. Arivazhagan, and S. Narayanan: Influence of filler metals on the weldability and mechanical properties of PC-GTA welded AISI 304L plates. Eur. J. Sci. Res. 97 (4), 489–496 (2013).

E. Farahani, M. Shamanian, and F. Ashrafizadeh: A comparative study on direct and pulsed current gas tungsten arc welding of alloy 617. AMAE Int. J. Manuf. Mater. Sci. 02 (01), 1–6 (2012).

G. Madhusudhan Reddy, A.A. Gokhale, and K. Prasad Rao: Weld microstructure refinement in a 1441 grade aluminium-lithium alloy. J. Mater. Sci. 32 (15), 4117–4126 (1997).

K. Devendranath Ramkumar, P. Mithilesh, D. Varun, A.R.G. Reddy, N. Arivazhagan, S. Narayanan, and K. Gokul Kumar: Characterization of microstructure and mechanical properties of Inconel 625 and AISI 304 dissimilar weldments. ISIJ Int. 54 (4), 900–908 (2014).

ASM Handbook on Mechanical Testing and Evaluation, Vol. 8 (ASM International, 2000).

S. Kou and Y.K. Yang: Fusion-boundary macro-segregation in dissimilar-filler welds. Weld. J. 86, 303s–312s, (2007).

J.N. DuPont, J.C. Lippold, and S.D. Kiser: Welding Metallurgy and Weldability of Nickel-Base Alloys (John Wiley & Sons, Inc., Hoboken, New Jersey, 2009).

G.R. Mirshekari, E. Tavakoli, M. Atapour, and B. Sadeghian: Microstructure and corrosion behaviour of multipass gas tungsten arc welded 304L stainless steel. Mater. Des. 55, 905–911 (2014).

B. Gideon, L. Ward, and G. Biddle: Duplex stainless steel welds and their susceptibility to intergranular corrosion. J. Miner. Mater. Charact. Eng. 7 (3), 247–263 (2008).

M. Rahmani, A. Eghlimi, and M. Shamanian: Evaluation of microstructure and mechanical properties in dissimilar austenitic/super duplex stainless steel joint. J. Mater. Eng. Perform. 23, 3745–3753 (2014).

C.D. Lundin and C.P.D. Chou: Fissuring in the Hazard HAZ region of austenitic stainless steel welds. Weld. J. 64 (4), 113s–118s (1985).

M.H. Chen and C.P. Chou: Effect of thermal cycles on ferrite content of austenitic stainless steel. Sci. Technol. Weld. Joining 4, 58 (1999).

Norsok Standard M601: Welding and Inspection of Piping, 5th ed. (Standards Norway, Lysaker, Norway, 2008).

K. Sindo. Welding Metallurgy, 2nd ed. (John Wiley & Sons Inc., Hoboken, New Jersey, 2003).

E.J. Barnhouse and J.C. Lippold: Microstructure/property relationships in dissimilar welds between duplex stainless steels and carbon steels. Weld. J. 77 (12), 477s–487s (1998).

K. Devendranath Ramkumar, G. Thiruvengatam, S.P. Sudharsan, D. Mishra, N. Arivazhagan, and R. Sridhar: Characterization of weld strength and impact toughness in the multi-pass welding of super-duplex stainless steel UNS 32750. Mater. Des. 60, 125–135 (2014).

A. Fuji, T.H. North, K. Ameyama, and M. Futamata: Improving tensile strength and bend ductility of titanium/AISI 304L stainless steel friction welds. Mater. Sci. Technol. 8 (3), 219–235 (1992).

ACKNOWLEDGMENTS

The authors wish to convey their sincere thanks to Mr. Natarajan, Delta Wear Tech Engineers Pvt. Ltd. Chennai for providing the welding facilities. The authors are grateful to DST – FIST for providing Instron UTM facility to our VIT University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Contributing Editor: Jürgen Eckert

Rights and permissions

About this article

Cite this article

Ramkumar, K.D., Choudhary, A., Aggarwal, S. et al. Characterization of microstructure and mechanical properties of continuous and pulsed current gas tungsten arc welded superaustenitic stainless steel. Journal of Materials Research 30, 1727–1746 (2015). https://doi.org/10.1557/jmr.2015.111

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2015.111