Abstract

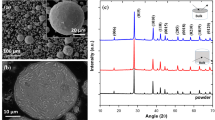

Highly textured, ultrafine grain pure Bi2Te3 has been obtained by applying large-strain high-pressure torsion (HPT) to hot-pressed (HP) coarse grain material. Its thermal conductivity is significantly smaller than the conductivity of HP Bi2Te3, and its crystallographic texture and mechanical properties significantly improved. The mechanical properties of both, coarse grain and ultrafine grain, samples have been assessed by compression tests of 2 µm diameter micropillars machined by focused ion beam. The micropillars built from coarse grain samples are single crystalline, those built from ultrafine grain materials are an order of magnitude larger than their grain size. The test results put in evidence the elastic and plastic anisotropy of Bi2Te3 and the significant strengthening and toughening effect of ultrafine grain refining. For instance, after an equivalent strain of about 100, the Vickers hardness (in kg mm−2) increases from 60 to 120. Simultaneously, about a 40% reduction of the thermal conductivity has been measured, and a very strong basal texture is developed normal to the torsion axis. Such combination of properties looks very promising for simultaneously enhancing the thermoelectric figure of merit and the mechanical reliability of Bi2Te3-based alloys through HPT processing.

Similar content being viewed by others

References

S.B. Riffat and X. Ma: Thermoelectrics: A review of present and potential applications. Appl. Therm. Eng. 23(8), 913 (2003).

D.M. Rowe: Thermoelectrics Handbook: Macro to Nano (CRC Press, London, New York, Tokyo, 2006); pp. 1–5.

A.J. Minnich, M.S. Dresselhaus, Z.F. Ren, and G. Chen: Bulk nanostructured thermoelectric materials: Current research and future prospects. Energy Environ. Sci. 2, 466 (2009).

D.H. Kim and T. Mitani: Thermoelectric properties of fine-grained Bi2Te3 alloys. J. Alloys Compd. 399, 14 (2005).

Z. Zhang, P.A. Sharma, E.J. Lavernia, and N. Yang: Thermoelectric and transport properties of nanostructured Bi2Te3 by spark plasma sintering. J. Mater. Res. 26(3), 475 (2011).

J.O. Jenkins and J.A. Rayne: Elastic moduli of Bi2Te3 from 4.2 to 300 K. Phys. Lett. A 30(6), 349 (1969).

D.M. Rowe: CRC Handbook of Thermoelectrics (CRC Press, London, New York, Washington, D.C., 1995).

H.W. Jeon, H.P. Ha, D-B. Hyun, and J.D. Shim: Electrical and thermoelectrical properties of undoped Bi2Te3-Sb2Te3 and Bi2Te3-Sb2Te3-Sb2Se3 single crystals. J. Phys. Chem. Solids 52(4), 579 (1991).

T.E. Svechnikova, L.E. Shelimova, P.P. Konstantinov, M.A. Kretova, E.S. Avilov, V.S. Zemskov, C. Stiewe, and A. Zuber: Thermoelectric properties. Inorg. Mater. 41(10), 1043–1049 (2005).

J. Jiang, L. Chen, S. Bai, Q. Yao, and Q. Wang: Thermoelectric properties of p-type (Bi2Te3)x(Sb2Te3)1−x crystals prepared via zone melting. J. Cryst. Growth 277, 258 (2005).

D.H. Kim, C. Kim, K-C. Je, G.H. Ha, and H. Kim: Fabrication and thermoelectric properties of c-axis-aligned Bi0.5Sb1.5Te3 with a high magnetic field. Acta Mater. 59(12), 4957 (2011).

R. Valiev, R. Islamgaliev, and I. Alexandrov: Bulk nanostructured materials from severe plastic deformation. Prog. Mater. Sci. 45(2), 103 (2000).

L.D. Zhao, B-P. Zhang, W.S. Liu, H.L. Zhang, and J-F. Li: Effects of annealing on electrical properties of n-type Bi2Te3 fabricated by mechanical alloying and spark plasma sintering. J. Alloys Compd. 467, 91 (2009).

L.P. Hu, X.H. Liu, H.H. Xie, J.J. Shen, T.J. Zhu, and X.B. Zhao: Improving thermoelectric properties of n-type bismuth–telluride-based alloys by deformation-induced lattice defects and texture enhancement. Acta Mater. 60(11), 4431 (2012).

L.D. Zhao, B-P. Zhang, J-F. Li, H.L. Zhang, and W.S. Liu: Enhanced thermoelectric and mechanical properties in textured n-type Bi2Te3 prepared by spark plasma sintering. Solid State Sci. 10(5), 651 (2008).

H. Böttner, D.G. Ebling, A. Jacquot, J. König, L. Kirste, and J. Schmidt: Structural and mechanical properties of spark plasma sintered n- and p-type bismuth telluride alloys. Phys. Status Solidi RRL 1(6), 235 (2007).

M.D. Uchic and D.M. Dimiduk: A methodology to investigate size scale effects in crystalline plasticity using uniaxial compression testing. Mater. Sci. Eng., A 400–401, 268 (2005).

C.A. Volkert and E.T. Lilleodden: Size effects in the deformation of sub-micron Au columns. Philos. Mag. 86(33–35), 5567 (2006).

G. Kavei and M.A. Karami: Formation of anti-site defects and bismuth overstoichiometry in p-type Sb2−xBixTe3 thermoelectric crystals. Eur. Phys. J. Appl. Phys. 42, 67 (2008).

Š. Mikmeková, K. Matsuda, K. Watanabe, S. Ikeno, I. Müllerová, and L. Frank: FIB induced damage examined with the low energy SEM. Mater. Trans. 52(3), 292 (2011).

D. Kiener, C. Motz, M. Rester, M. Jenko, and G. Dehm: FIB damage of Cu and possible consequences for miniaturized mechanical tests. Mater. Sci. Eng., A 459(1–2), 262 (2007).

S. Rubanov and P.R. Munroe: FIB-induced damage in silicon. J. Microsc. 214, 213 (2004).

R. Soler, J.M. Molina-Aldareguia, J. Segurado, J. Llorca, R.I. Merino, and V.M. Orera: Micropillar compression of LiF [111] single crystals: Effect of size, ion irradiation and misorientation. Int. J. Plast. 36, 50 (2012).

A. Zhilyaev and T. Langdon: Using high-pressure torsion for metal processing: Fundamentals and applications. Prog. Mater. Sci. 53(6), 893 (2008).

D. Kiener, C. Motz, and G. Dehm: Micro-compression testing: A critical discussion of experimental constraints. Mater. Sci. Eng., A 505(1–2), 79 (2009).

N. Li, N.A. Mara, Y.Q. Wang, M. Nastasi, and A. Misra: Compressive flow behavior of Cu thin films and Cu/Nb multilayers containing nanometer-scale helium bubbles. Scr. Mater 64(10), 974 (2011).

S. Lotfian, J.M. Molina-Aldareguia, K.E. Yazzie, J. Llorca, and N. Chawla: High-temperature nanoindentation behavior of Al/SiC multilayers. Philos. Mag. Lett. 92(8), 362 (2012).

M.D. Uchic, P.A. Shade, and D.M. Dimiduk: Plasticity of micrometer-scale single crystals in compression. Annu. Rev. Mater. Res. 39(1), 361 (2009).

J.R. Greer and J.T.M. De Hosson: Plasticity in small-sized metallic systems: Intrinsic versus extrinsic size effect. Prog. Mater. Sci. 56(6), 654 (2011).

J.R. Greer, W.C. Oliver, and W.D. Nix: Size dependence of mechanical properties of gold at the micron scale in the absence of strain gradients. Acta Mater 53(6), 1821 (2005).

W.C. Oliver and G.M. Pharr: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7(6), 1565 (1992).

L.M. Pavlova, Y.I. Shtern, and R.E. Mironov: Thermal expansion of bismuth telluride. High Temp. 49(3), 369 (2011).

H. Hans Landolt, R. Börnstein, K.H. Hellwege, R. Clasen, M. Schulz, H. Weiss, and O. Madelung: Numerical Data and Functional Relationships in Science and Technology. Group 3, Crystal and Solid State Physics. Vol. 17, Semiconductors, Springer: Berlin, 1983.

K.E. Spear: Diamond-ceramic coating of the future. J. Am. Ceram. Soc. 72(2), 171 (1989).

T. Zühlke: Thermomechanical and microstructural properties of ZnCuTi under different deformation conditions. Ph.D. Thesis, Tecnun. Universidad de Navarra, 2014.

B. Srinivasarao, A.P. Zhilyaev, T.G. Langdon, and M.T. Pérez-Prado: On the relation between the microstructure and the mechanical behavior of pure Zn processed by high pressure torsion. Mater. Sci. Eng., A 562, 196 (2013).

I.N. Sneddon: The relation between load and penetration in the axisymmetric boussinesq problem for a punch of arbitrary profile. Int. J. Eng. Sci. 3, 47 (1965).

H. Zhang, B.E. Schuster, Q. Wei, and K.T. Ramesh: The design of accurate micro-compression experiments. Scr. Mater. 54(2), 181 (2006).

E. Lilleodden: Microcompression study of Mg (0 0 0 1) single crystal. Scr. Mater. 62(8), 532 (2010).

E.W. Kelley and W.F. Hosford: Plane-strain compression of magnesium and magnesium alloy crystals. Trans. Metall. Soc. AIME 242, 5 (1968).

L-D. Zhao, B-P. Zhang, J-F. Li, M. Zhou, W-S. Liu, and J. Liu: Thermoelectric and mechanical properties of nano-SiC-dispersed Bi2Te3 fabricated by mechanical alloying and spark plasma sintering. J. Alloys Compd. 455(1–2), 259 (2008).

H. Kim and S. Hong: Compound prepared by high energy milling and hot extrusion. Curr. Nanosci. 10, 118 (2014).

K. Niihara, R. Morena, and O. Metals: Evaluation of KIc of brittle solids by the indentation method with low crack-to-indent ratios. J. Mater. Sci. Lett. 1, 13, (1982).

J.E. Ni, E.D. Case, K.N. Khabir, R.C. Stewart, C-I. Wu, T.P. Hogan, E.J. Timm, S.N. Girard, and M.G. Kanatzidis: Room temperature Young’s modulus, shear modulus, Poisson’s ratio and hardness of PbTe–PbS thermoelectric materials. Mater. Sci. Eng., B 170(1–3), 58 (2010).

J. Eilertsen, M.A. Subramanian, and J.J. Kruzic: Fracture toughness of Co4Sb12 and In0.1Co4Sb12 thermoelectric skutterudites evaluated by three methods. J. Alloys Compd. 552, 492 (2013).

W.D. Nix and H. Gao: Indentation size effects in crystalline materials: A law for strain gradient plasticity. J. Mech. Phys. Solids 46, 411–425 (1998).

J. Alkorta, J.M. Martínez-Esnaola, and J. Gil Sevillano: Detailed assessment of indentation size-effect in recrystallized and highly deformed niobium. Acta Mater. 54, 3445–3452 (2006).

L. Yang, J.S. Wu, and L.T. Zhang: Synthesis of filled skutterudite compound La0.75Fe3CoSb12 by spark plasma sintering and effect of porosity on thermoelectric properties. J. Alloys Compd. 364(1–2), 83 (2004).

H. Julian Goldsmith: Introduction to Thermoelectricity (Springer-Verlag, London, New York, 2010).

W. Xie, S. Wang, S. Zhu, J. He, X. Tang, Q. Zhang, and T.M. Tritt: High performance Bi2Te3 nanocomposites prepared by single-element-melt-spinning spark-plasma sintering. J. Mater. Sci. 48(7), 2745 (2012).

J.M. Schultz, J.P. McHugh, and W.A. Tiller: Effects of heavy deformation and annealing on the electrical properties of Bi2Te3. J. Appl. Phys. 33(8), 2443 (1962).

J. Navrátil, Z. Starý, and T. Plechácek: Thermoelectric properties of p-type antimony bismuth telluride alloys prepared by cold pressing. Mater. Res. Bull. 31(12), 1559 (1996).

L. Hu, T. Zhu, X. Liu, and X. Zhao: Point defect engineering of high-performance bismuth-telluride-based thermoelectric materials. Adv. Funct. Mater. 24, 5211 (2014).

ACKNOWLEDGMENTS

Financial assistance from the Spanish Ministry of Industry, Energy and Competitiveness (MINECO) under the project MAT2010-17958, from the Basque Government, Dept. of Education, action EC2013-06 and from BELSPO, under the Belgian Federal Interuniversity Attraction Poles Program, INTEMATE project, IAP P7/21 is gratefully acknowledged. JAS acknowledges support from MINECO through an FPI grant.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Santamaría, J.A., Alkorta, J. & Sevillano, J.G. Microcompression tests of single-crystalline and ultrafine grain Bi2Te3 thermoelectric material. Journal of Materials Research 30, 2593–2604 (2015). https://doi.org/10.1557/jmr.2015.170

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2015.170