Abstract

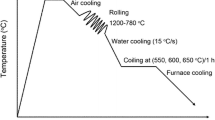

A new ultrahigh strength hot rolled Ti-Mo-bearing ferritic steel was developed through chemical composition design and rolling processing optimization. To maximize the potential of nanometer-sized (Ti, Mo)C carbide in terms of strengthening ferrite matrix, the optimal chemical composition of 0.1C-0.2Ti-0.4Mo (wt%) was determined through considering the atomic ratio of elements, the solubility temperature of (Ti, Mo)C in austenite, and the excessive growth critical temperature of austenite grain during reheating. The rolling condition in the region through austenite recrystallization region to austenite nonrecrystallization region was adopted to realize a homogenous and fine ferrite grain structure. Results showed that the simulated coiling at 600 °C was found to provide an attractive combination of ferrite grain refinement hardening (360 MPa) and precipitation hardening (324 MPa). An optimal combination of strength and ductility was achieved after coiling at 600 °C (yield strength: 912 MPa; ultimate tensile strength: 971 MPa; total elongation: 16.0%). In addition, the nanometer-sized (Ti, Mo)C carbide was characterized by transmission electron microscopy (TEM) and physical-chemical phase analysis, and its role was discussed in details.

Similar content being viewed by others

References

Y. Funakawa, T. Shiozaki, K. Tomita, T. Yamamoto, and E. Maeda: Development of high strength hot-rolled sheet steel consisting of ferrite and nanometer-sized carbides. ISIJ Int. 44, 1945–1951 (2004).

T. Gladman: The Physical Metallurgy of Microalloyed Steels, 2nd ed. (The Institute of Materials, London, 1997).

C.Y. Chen, H.W. Yen, F.H. Kao, W.C. Li, C.Y. Huang, J.R. Yang, and S.H. Wang: Precipitation hardening of high-strength low-alloy steels by nanometer-sized carbides. Mater. Sci. Eng., A 499, 162–166 (2009).

X.G. Duan, Q.W. Cai, and H.B. Wu: Ti–Mo ferrite micro-alloy steel with nanometer-sized precipitates. Acta Metall. Sin. 47, 251–256 (2011).

B.H. Hu: Mater Dissertation, University of Science and Technology Beijing, 2012.

N. Kamikawa, Y. Abe, G. Miyamoto, Y. Funakawa, and T. Furuhara: Tensile behavior of Ti, Mo-added low carbon steels with interphase precipitation. ISIJ Int. 54, 212–221 (2014).

H.W. Yen, P.Y. Chen, C.Y. Huang, and J.R. Yang: Interphase precipitation of nanometer-sized carbides in a titanium–molybdenum-bearing low-carbon steel. Acta Mater. 59, 6264–6274 (2011).

Y. Funakawa and K. Seto: Coarsening behavior of nanometer-sized carbides in hot-rolled high strength sheet steel. Mater. Sci. Forum 539, 4813–4818 (2007).

Y.W. Kim, S.W. Song, S.J. Seo, S. Hong, and C.S. Lee: Development of Ti and Mo micro-alloyed hot-rolled high strength sheet steel by controlling thermomechanical controlled processing schedule. Mater. Sci. Eng., A 565, 430–438 (2013).

C.F. Sun, Q.W. Cai, H.B.W, H.Y. Mao, and H.Z. Chen: Effect of controlled rolling processing on nanometer-sized carbonitride of Ti–Mo ferrite matrix microalloyed steel. Acta Metall. Sin. 48, 1415–1421 (2012).

Y.W. Kim, S.G. Hong, Y.H. Huh, and C.S. Lee: Role of temperature in the precipitation hardening characteristics of Ti–Mo microalloyed hot-rolled high strength steel. Mater. Sci. Eng., A 615, 255–261 (2014).

Y.W. Kim, J.H. Kim, S.G. Hong, and C.S. Lee: Effects of rolling temperature on the microstructure and mechanical properties of Ti–Mo microalloyed hot-rolled high strength steel. Mater. Sci. Eng., A 605, 244–252 (2014).

X.G. Duan, Q.W. Cai, H.B. Wu, and D. Tang: Precipitation law of ultra fine carbides in ferrite matrix Ti–Mo microalloyed steel. J. Univ. Sci. Technol. Beijing 34, 644–650 (2012).

G. Jha, S. Das, A. Lodh, and A. Haldar: Development of hot rolled steel sheet with 600 MPa UTS for automotive wheel application. Mater. Sci. Eng., A 552, 457–463 (2012).

G. Jha, S. Das, S. Sinha, A. Lodh, and A. Haldar: Design and development of precipitate strengthened advanced high strength steel for automotive application. Mater. Sci. Eng., A 561, 394–402 (2013).

D.L. Li, J.F. Fang, Q.B. Liu, C.F. Lu, and J.Y. Zhang: Determination of particle size of precipitate phase in steel and alloy by small angle X-ray scattering method. Metall. Anal. 28, 1–8 (2008).

C.J. Wang, X.J. Sun, Q.L. Yong, Z.D. Li, X. Zhang, and L. Jiang: Effect of banitic transformation temperature on the microstructure and mechanical properties of the rolled trip steel containing Ti and Mo and its precipitation characteristics. Acta Metall. Sin. 49, 399–407 (2013).

F.B. Picking: Physical metallurgy and the design of steels (Applied Science Publishers Ltd., London, 1978).

X.P. Mao, X.D. Huo, X.J. Sun, Y.Z. Cai: Strengthening mechanisms of a new 700 MPa hot rolled Ti-microalloyed steel produced by compact strip production. J. Mater. Process. Technol., 210, 1660–1666 (2010).

Q.L. Yong, M.T. Ma, and B.R. Wu: Microalloyed Steel-Physical, and Mechanical Metallurgy (China Machine Press, Beijing, 1989).

N.J. Petch: The cleavage strength of polycrystals. J. Iron Steel Inst., London 174, 25–28 (1953).

N.J. Petch: The ductile-brittle transition in the fracture of a-iron. Philos. Mag. 34, 1089–1097 (1958).

Q.L. Yong: Secondary Phases in Steel (Metallurgical Industry Press, Beijing, 2006).

Y.F. Shen, C.M. Wang, and X. Sun: A micro-alloyed ferritic steel strengthened by nanoscale precipitates. Mater. Sci. Eng., A 528, 8150–8156 (2011).

J.E. Bailey and P.B. Hirsch: The dislocation distribution, flow stress, and stored energy in cold-worked polycrystalline silver. Philos. Mag. 5, 485–497 (1960).

G.Y. Chin and W.L. Mammel: T Computer solutions of Taylor analysis for axisymmetric flow. Trans. Metall. Soc. AIME 239, 1400–1409 (1967).

A.S. Keh: Work hardening and deformation sub-structure in iron single crystals deformed in tension at 298 K. Philos. Mag. 12, 9–30 (1965).

K. Zhang, Q.L. Yong, X.J. Sun, Z.D. Li, P.L. Zhao, and S.D. Chen: Effect of tempering temperature on microstructure and mechanical properties of high Ti microalloyed directly quenched high strength steel. Acta Metall. Sin. 50, 913–920 (2014).

B. Dutta, E. Valdes, and C.M. Sellars: Mechanism and kinetics of strain induced precipitation of Nb (C, N) in austenite. Acta Mater. 40, 653–662 (1992).

B. Dutta, E.J. Palmiere, and C.M. Sellars: Modelling the kinetics of strain induced precipitation in Nb microalloyed steels. Acta Mater. 49, 785–794 (2001).

Y.L. Kang: Theory and technology of processing and forming for advanced automobile steel sheets (Metallurgical Industry Press, Beijing, 2009).

R. Lagneborg and S. Zajac: A model for interphase precipitation in V-microalloyed structural steels. Metall. Mater. Trans. A 32, 39–50 (2001).

E. Pereloma, B. Crawford, and P. Hodgson: Strain-induced precipitation behavior in hot rolled strip steel. Mater. Sci. Eng., A 299, 27–37 (2001).

Z.Q. Wang: PhD Thesis, Tsinghua University, Beijing, 2013.

R.W.K. Honeycombe and R.F. Mehl: Transformation from austenite in alloy steels. Metall. Trans. A 7, 915–936 (1976).

R.M. Smith and D.P. Dunne: Structural aspects of alloy carbonitride precipitation in microalloyed steels. Materials Forum, 11, 166–181.

D.A. Porter, K.E. Easterling, and M. Sherif: Phase Transformations in Metals and Alloys, (Revised Reprint) (CRC Press, Boca Raton, 2009).

Z.Q. Wang, X.J. Sun, Z.G. Yang, Q.L. Yong, Z. Zhang, Z.D. Li, and Y.Q. Weng: Carbide precipitation in austenite of a Ti–Mo-containing low-carbon steel during stress relaxation. Mater. Sci. Eng., A 573, 84–91 (2013).

ACKNOWLEDGMENTS

This research was financially supported by the National Basic Research Program of China (No. 2015CB654803), National Natural Science Foundation of China (No. 51201036), National Science and Technology Pillar Program (No. 2013BAE07B05), and Foundation of China Iron and Steel Research Institute Group.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Zhang, K., Li, Z., Wang, Z. et al. Precipitation behavior and mechanical properties of hot-rolled high strength Ti-Mo-bearing ferritic sheet steel: The great potential of nanometer-sized (Ti, Mo)C carbide. Journal of Materials Research 31, 1254–1263 (2016). https://doi.org/10.1557/jmr.2016.154

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2016.154