Abstract

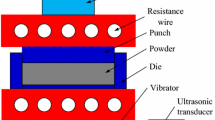

SiC nanoparticles reinforced magnesium matrix composite was fabricated by ultrasonic vibration assisted squeeze casting. Since ultrasonic device could meet the use requirements according to theoretic calculation, uniform dispersion of SiC nanoparticles was expected to achieve. The grains of the composite were refined compared with the AZ91 alloy, which was related to the increase of nucleation sites during solidification and Zenner pinning effect caused by SiC nanoparticles. With increasing the ultrasonic power, grain size of the composite changed no obviously while the morphology of β-Mg17Al12 phase was significantly affected. The ultimate tensile strength, yield strength, and elongation to fracture of the composites fabricated under different ultrasonic powers were simultaneously improved compared with the AZ91 alloy. The increase of yield strength could be attributed to Hall–Petch strengthening and Orowan strengthening for the present composites. Theoretical value of the yield strength obtained by the square root method was close to the experimental value.

Similar content being viewed by others

References

D. Yu, D. Zhang, J. Sun, Y. Luo, J. Xu, H. Zhang, and F. Pan: Improving mechanical properties of ZM61 magnesium alloy by aging before extrusion. J. Alloys Compd. 690, 553 (2017).

Q. Chen, B.G. Yuan, G.Z. Zhao, D.Y. Shu, C.K. Hu, Z.D. Zhao, and Z.X. Zhao: Microstructural evolution during reheating and tensile mechanical properties of thixoforged AZ91D-RE magnesium alloy prepared by squeeze casting–solid extrusion. Mater. Sci. Eng., A 537, 25 (2012).

C. Xu, T. Nakata, X.G. Qiao, M.Y. Zheng, K. Wu, and S. Kamado: Ageing behavior of extruded Mg–8.2Gd–3.8Y–1.0Zn–0.4Zr (wt%) alloy containing LPSO phase and γ′ precipitates. Sci. Rep. 7, 43391 (2017).

Q. Chen, Z. Zhao, D. Shu, and Z. Zhao: Microstructure and mechanical properties of AZ91D magnesium alloy prepared by compound extrusion. Mater. Sci. Eng., A 528, 3930 (2011).

K.K. Deng, J.C. Li, F.J. Xu, and K.B. Nie: Hot deformation behavior and processing maps of fine-grained SiCp/AZ91 composite. Mater. Des. 67, 72 (2015).

H.Z. Ye and X.Y. Liu: Review of recent studies in magnesium matrix composites. J. Mater. Sci. 39 (20), 6153 (2004).

L. Chen, J. Xu, H. Choi, M. Pozuelo, X. Ma, S. Bhowmick, J. Yang, S. Mathaudhu, and X. Li: Processing and properties of magnesium containing a dense uniform dispersion of nanoparticles. Nature 528, 539 (2015).

C.S. Goh, J. Wei, L.C. Lee, and M. Gupta: Development of novel carbon nanotube reinforced magnesium nanocomposites using the powder metallurgy technique. Nanotechnology 17, 1 (2005).

Y.L. Xi, D.L. Chai, W.X. Zhang, and J.E. Zhou: Ti–6Al–4V particle reinforced magnesium matrix composite by powder metallurgy. Mater. Lett. 59, 1831 (2005).

Y. Yao and L. Chen: Processing of B4C particulate-reinforced magnesium-matrix composites by metal-assisted melt infiltration technique. J. Mater. Sci. Technol. 30, 661 (2014).

M. Azizieh, A.H. Kokabi, and P. Abachi: Effect of rotational speed and probe profile on microstructure and hardness of AZ31/Al2O3 nanocomposites fabricated by friction stir processing. Mater. Des. 32, 2034 (2011).

H. Dieringa: Properties of magnesium alloys reinforced with nanoparticles and carbon nanotubes: A review. J. Mater. Sci. 46, 289 (2011).

X.J. Wang, X.S. Hu, K. Wu, M.Y. Zheng, L. Zheng, and Q.J. Zhai: The interfacial characteristic of SiCp/AZ91 magnesium matrix composites fabricated by stir casting. J. Mater. Sci. 44, 2759 (2009).

M. Karbalaei Akbari, H.R. Baharvandi, and K. Shirvanimoghaddam: Tensile and fracture behavior of nano/micro TiB2 particle reinforced casting A356 aluminum alloy composites. Mater. Des. 66, 150 (2015).

M. Gupta and W.L.E. Wong: Magnesium-based nanocomposites: Lightweight materials of the future. Mater. Charact. 105, 30 (2015).

J. Lan, Y. Yang, and X. Li: Microstructure and microhardness of SiC nanoparticles reinforced magnesium composites fabricated by ultrasonic method. Mater. Sci. Eng., A 386, 284 (2004).

K.B. Nie, X.J. Wang, K. Wu, X.S. Hu, and M.Y. Zheng: Development of SiCp/AZ91 magnesium matrix nanocomposites using ultrasonic vibration. Mater. Sci. Eng., A 540, 123 (2012).

M.J. Shen, X.J. Wang, M.F. Zhang, X.S. Hu, M.Y. Zheng, and K. Wu: Fabrication of bimodal size SiCp reinforced AZ31B magnesium matrix composites. Mater. Sci. Eng., A 601, 58 (2014).

H.L. Shi, X.J. Wang, C.L. Zhang, C.D. Li, C. Ding, K. Wu, and X.S. Hu: A novel melt processing for Mg matrix composites reinforced by multiwalled carbon nanotubes. J. Mater. Sci. Technol. 32, 1303 (2016).

H. Hu: Squeeze casting of magnesium alloys and their composites. J. Mater. Sci. 33, 1579 (1998).

M. Zhou, H. Hu, N. Li, and J. Lo: Microstructure and tensile properties of squeeze cast magnesium alloy AM50. J. Mater. Eng. Perform. 14, 539 (2005).

A. Ramirez, M. Qian, B. Davis, T. Wilks, and D.H. StJohn: Potency of high-intensity ultrasonic treatment for grain refinement of magnesium alloys. Scr. Mater. 59, 19 (2008).

G.I. Eskin: Ultrasonic Treatment of Light Alloy Melts (Gordon and Breach Science Publishers, Amsterdam, 1998); pp. 135–240.

J. Li, T. Momono, Y. Tayu, and Y. Fu: Application of ultrasonic treating to degassing of metal ingots. Mater. Lett. 62, 4152 (2008).

K. Chen, Z.Q. Li, H.Z. Zhou, and W.K. Wang: Influence of high intensity ultrasonic vibration on microstructure of in situ synthesized Mg2Si/Mg composite. Trans. Nonferrous Met. Soc. China 17, 391 (2007).

M.P. De Cicco, L.S. Turng, X. Li, and J.H. Perepezko: Nucleation catalysis in aluminum alloy A356 using nanoscale inoculants. Metall. Mater. Trans. A 42, 2323 (2011).

E. Nes, N. Ryum, and O. Hunderi: On the zener drag. Acta Metall. 33, 11 (1985).

J.Q. Xu, L.Y. Chen, H. Choi, and X.C. Li: Theoretical study and pathways for nanoparticle capture during solidification of metal melt. J. Phys.: Condens. Matter 24, 255304 (2012).

Z.H. Wang, X.D. Wang, Y.X. Zhao, and W.B. Du: SiC nanoparticles reinforced magnesium matrix composites fabricated by ultrasonic method. Trans. Nonferrous Met. Soc. China 20, 1029 (2010).

P. Cao, Q. Ma, and D.H. StJohn: Effect of manganese on grain refinement of Mg–Al based alloys. Scr. Mater. 54, 1853 (2006).

Q. Chen, J. Lin, D. Shu, C. Hu, Z. Zhao, F. Kang, S. Huang, and B. Yuan: Microstructure development, mechanical properties and formability of Mg–Zn–Y–Zr magnesium alloy. Mater. Sci. Eng., A 554, 129 (2012).

C. Xu, T. Nakata, X. Qiao, M. Zheng, K. Wu, and S. Kamado: Effect of LPSO and SFs on microstructure evolution and mechanical properties of Mg–Gd–Y–Zn–Zr alloy. Sci. Rep. 7, 40846 (2017).

Z. Zhang and D.L. Chen: Consideration of Orowan strengthening effect in particulate-reinforced metal matrix nanocomposites: A model for predicting their yield strength. Scr. Mater. 54, 1321 (2006).

I. Shao, P.M. Vereecken, C.L. Chien, P.C. Searson, and R.C. Cammarata: Synthesis and characterization of particle-reinforced Ni/Al2O3 nanocomposites. J. Mater. Res. 17, 1412 (2002).

S.F. Hassan, M.J. Tan, and M. Gupta: High-temperature tensile properties of Mg/Al2O3 nanocomposite. Mater. Sci. Eng., A 486, 56 (2008).

Z. Zhang and D.L. Chen: Contribution of Orowan strengthening effect in particulate-reinforced metal matrix nanocomposites. Mater. Sci. Eng., A 483–484, 148 (2008).

G. Cao, J. Kobliska, H. Konishi, and X. Li: Tensile properties and microstructure of SiC nanoparticle–reinforced Mg–4Zn alloy fabricated by ultrasonic cavitation–based solidification processing. Metall. Mater. Trans. A 39, 880 (2008).

Q. Chen, D. Shu, C. Hu, Z. Zhao, and B. Yuan: Grain refinement in an as-cast AZ61 magnesium alloy processed by multi-axial forging under the multitemperature processing procedure. Mater. Sci. Eng., A 541, 98 (2012).

G. Cao, H. Choi, J. Oportus, H. Konishi, and X. Li: Study on tensile properties and microstructure of cast AZ91D/AlN nanocomposites. Mater. Sci. Eng., A 494, 127 (2008).

A. Sanaty-Zadeh: Comparison between current models for the strength of particulate-reinforced metal matrix nanocomposites with emphasis on consideration of Hall–Petch effect. Mater. Sci. Eng., A 531, 112 (2012).

L.H. Dai, Z. Ling, and Y.L. Bai: Size-dependent inelastic behavior of particle-reinforced metal–matrix composites. Compos. Sci. Technol. 61, 1057 (2001).

C.S. Goh, J. Wei, L.C. Lee, and M. Gupta: Properties and deformation behaviour of Mg–Y2O3 nanocomposites. Acta Mater. 55, 5115 (2007).

Q.B. Nguyen and M. Gupta: Enhancing compressive response of AZ31B using nano-Al2O3 and copper additions. J. Alloys Compd. 490, 382 (2010).

ACKNOWLEDGMENTS

This work was financially supported by “National Natural Science Foundation of China” (Grant Nos. 51401144 and 51471059), and the “Natural Science Foundation of Shanxi” (Grant No. 2015021067).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nie, K., Deng, K., Wang, X. et al. Characterization and strengthening mechanism of SiC nanoparticles reinforced magnesium matrix composite fabricated by ultrasonic vibration assisted squeeze casting. Journal of Materials Research 32, 2609–2620 (2017). https://doi.org/10.1557/jmr.2017.202

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2017.202