Abstract

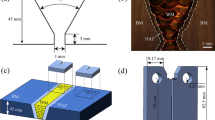

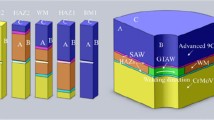

The impact toughness and related microstructure of the dissimilar 9Cr/NiCrMoV welded joint fabricated by narrow-gap submerged arc welding were systematically investigated in the paper. Results indicated that the fracture appearance transition temperature (50% FATT) for weld metal was −11 °C, while low and scattered absorbed energies determined by different crack growth paths for the heat affected zone of 9Cr were gained which could not satisfy the requirement of service. However, a dramatically enhanced impact toughness was obtained by optimizing the post-weld heat treatment (PWHT) process. Microstructure characterization revealed that the microstructure evolution from martensitic laths in the previous PWHT metals to a softer ferrite matrix with the supersaturated carbon precipitating from the matrix led to higher toughness in the optimized PWHT materials. In addition, the observation of the fracture morphology found that the fractography varied from brittle fracture to a fracture mode with both brittle and ductile fracture feature with the change of crack growth paths in 9Cr-HAZ.

Similar content being viewed by others

References

S. Barella, M. Bellogini, M. Boniardi, and S. Cincera: Failure analysis of a steam turbine rotor. Eng. Failure Anal. 18, 1511–1519 (2011).

Q. Wu, F. Lu, H. Cui, Y. Ding, and Y. Gao: Microstructure characteristics and temperature-dependent high cycle fatigue behavior of advanced 9% Cr/CrMoV dissimilarly welded joint. Mater. Sci. Eng., A 615, 98–106 (2014).

X. Long, G. Cai, and L-E. Svensson: Investigation of fracture and determination of fracture toughness of modified 9Cr–1Mo steel weld metals using AE technique. Mater. Sci. Eng., A 270, 260–266 (1999).

A. Moitra, P. Parameswaran, P. Sreenivasan, and S. Mannan: A toughness study of the weld heat-affected zone of a 9Cr–1Mo steel. Mater. Charact. 48, 55–61 (2002).

X. Wang, Q. Shi, X. Wang, and Z. Zhang: The influences of precrack orientations in welded joint of Ti–6Al–4V on fatigue crack growth. Mater. Sci. Eng., A 527, 1008–1015 (2010).

M. Zhu and F. Xuan: Effects of temperature on tensile and impact behavior of dissimilar welds of rotor steels. Mater. Des. 31, 3346–3352 (2010).

Q. Gao, X. Di, Y. Liu, and Z. Yan: Recovery and recrystallization in modified 9Cr–1Mo steel weldments after post-weld heat treatment. Int. J. Pressure Vessels Piping 93, 69–74 (2012).

A. Aloraier, R. Ibrahim, and J. Ghojel: Eliminating post-weld heat treatment in repair welding by temper bead technique: Role bead sequence in metallurgical changes. J. Mater. Process. Technol. 153, 392–400 (2004).

H. Wang, H. Zhang, and J. Li: Microstructural evolution of 9Cr–1Mo deposited metal subjected to weld heating. J. Mater. Process. Technol. 209, 2803–2811 (2009).

K. Bang, C. Park, H. Jung, and J. Lee: Effects of flux composition on the element transfer and mechanical properties of weld metal in submerged arc welding. Met. Mater. Int. 15, 471–477 (2009).

Y. Chao, J. Ward, and R. Sands: Charpy impact energy, fracture toughness and ductile–brittle transition temperature of dual-phase 590 Steel. Mater. Des. 28, 551–557 (2007).

S. Song, H. Zhuang, J. Wu, L. Weng, Z. Yuan, and T. Xi: Dependence of ductile-to-brittle transition temperature on phosphorus grain boundary segregation for a 2.25Cr1Mo steel. Mater. Sci. Eng., A 486, 433–438 (2008).

L. Ceschini, A. Marconi, C. Martini, A. Morri, and A. Di Schino: Tensile and impact behaviour of a microalloyed medium carbon steel: Effect of the cooling condition and corresponding microstructure. Mater. Des. 45, 171–178 (2013).

M. Taneike, K. Sawada, and F. Abe: Effect of carbon concentration on precipitation behavior of M23C6 carbides and MX carbonitrides in martensitic 9Cr steel during heat treatment. Metall. Mater. Trans. A 35, 1255–1262 (2004).

Y. You, R. Shiue, R. Shiue, and C. Chen: The study of carbon migration in dissimilar welding of the modified 9Cr–1Mo steel. J. Mater. Sci. Lett. 20, 1429–1432 (2001).

Y. Im, Y. Oh, B. Lee, J. Hong, and H. Lee: Effects of carbide precipitation on the strength and Charpy impact properties of low carbon Mn–Ni–Mo bainitic steels. J. Nucl. Mater. 297, 138–148 (2001).

Z. Zhu, L. Kuzmikova, M. Marimuthu, H. Li, and F. Barbaro: Role of Ti and N in line pipe steel welds. Sci. Technol. Weld. Joining 18, 1–10 (2013).

H. Sung, S. Shin, W. Cha, K. Oh, S. Lee, and N. Kim: Effects of acicular ferrite on charpy impact properties in heat affected zones of oxide-containing API X80 linepipe steels. Mater. Sci. Eng., A 528, 3350–3357 (2011).

A. Guo, S. Li, J. Guo, P. Li, Q. Ding, K. Wu, and X. He: Effect of zirconium addition on the impact toughness of the heat affected zone in a high strength low alloy pipeline steel. Mater. Charact. 59, 134–139 (2008).

L. Lan, C. Qiu, D. Zhao, X. Gao, and L. Du: Microstructural characteristics and toughness of the simulated coarse grained heat affected zone of high strength low carbon bainitic steel. Mater. Sci. Eng., A 529, 192–200 (2011).

Z. Zhu, J. Han, H. Li, and C. Lu: High temperature processed high Nb X80 steel with excellent heat-affected zone toughness. Mater. Lett. 163, 171–174 (2016).

J. Wang, S. Lu, L. Rong, and D. Li: Effect of silicon contents on the microstructures and mechanical properties of heat affected zones for 9Cr2WVTa steels. J. Nucl. Mater. 470, 1–12 (2016).

Z. Zhang, Z. Wang, W. Wang, Z. Yan, P. Dong, H. Du, and M. Ding: Microstructure evolution in heat affected zone of T4003 ferritic stainless steel. Mater. Des. 68, 114–120 (2015).

J. Wang, S. Lu, W. Dong, D. Li, and L. Rong: Microstructural evolution and mechanical properties of heat affected zones for 9Cr2WVTa steels with different carbon contents. Mater. Des. 64, 550–558 (2014).

P. Sreenivasan: Application of a cleavage fracture stress model for estimating the ASTM E-1921 reference temperature of ferritic steels from instrumented impact test of CVN specimens without precracking. Procedia Eng. 86, 272–280 (2014).

S. Norris: The influence of non-metallic inclusions on the prediction of 50% FATT using the miniaturised disk bend test. Int. J. Pressure Vessels Piping 74, 249–258 (1997).

M. Zhu and F. Xuan: Correlation between microstructure, hardness and strength in HAZ of dissimilar welds of rotor steels. Mater. Sci. Eng., A 527, 4035–4042 (2010).

Q. Wu, F. Lu, H. Cui, X. Liu, P. Wang, and X. Tang: Role of butter layer in low-cycle fatigue behavior of modified 9Cr and CrMoV dissimilar rotor welded joint. Mater. Des. 59, 165–175 (2014).

Q. Wu, F. Lu, H. Cui, X. Liu, P. Wang, and Y. Gao: Soft zone formation by carbon migration and its effect on the high-cycle fatigue in 9% Cr–CrMoV dissimilar welded joint. Mater. Lett. 141, 242–244 (2015).

S. Ashrafizadeh and A. Eivani: Correlative evolution of microstructure, particle dissolution, hardness and strength of ultrafine grained AA6063 alloy during annealing. Mater. Sci. Eng., A 644, 284–296 (2015).

L. Ceschini, A. Morri, A. Morri, and G. Pivetti: Predictive equations of the tensile properties based on alloy hardness and microstructure for an A356 gravity die cast cylinder head. Mater. Des. 32, 1367–1375 (2011).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Liu, X., Cai, Z., Deng, X. et al. Investigation on the weakest zone in toughness of 9Cr/NiCrMoV dissimilar welded joint and its enhancement. Journal of Materials Research 32, 3117–3127 (2017). https://doi.org/10.1557/jmr.2017.222

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2017.222