Abstract

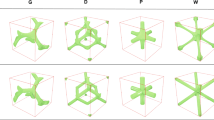

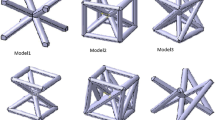

Architected materials are materials engineered to utilize their topological aspects to enhance the related physical and mechanical properties. With the witnessed progressive advancements in fabrication techniques, obstacles and challenges experienced in manufacturing geometrically complex architected materials are mitigated. Different strut-based architected lattice structures have been investigated for their topology-property relationship. However, the focus on lattice design has recently shifted toward structures with mathematically defined architectures. In this work, we investigate the architecture-property relationship associated with the possible configurations of employing the mathematically attained Schoen’s I-WP (IWP) minimal surface to create lattice structures. Results of mechanical testing showed that sheet-based IWP lattice structures exhibit a stretching-dominated behavior with the highest structural efficiency as compared to other forms of strut-based and skeletal-based lattice structures. This study presents experimental and computational evidence of the robustness and suitability of sheet-based IWP structures for different engineering applications, where strong and lightweight materials with exceptional energy absorption capabilities are required.

Similar content being viewed by others

References

F. Javid, P. Wang, A. Shanian, and K. Bertoldi: Architected materials with ultra-low porosity for vibration control. Adv. Mater. 28, 5943 (2016).

S. Babaee, N. Viard, P. Wang, N.X. Fang, and K. Bertoldi: Harnessing deformation to switch on and off the propagation of sound. Adv. Mater. 28, 1631 (2016).

X. Zheng, W. Smith, J. Jackson, B. Moran, H. Cui, D. Chen, J. Ye, N. Fang, N. Rodriguez, and T. Weisgraber: Multiscale metallic metamaterials. Nat. Mater. 15, 1100 (2016).

B. Haghpanah, L. Salari-Sharif, P. Pourrajab, J. Hopkins, and L. Valdevit: Multistable shape-reconfigurable architected materials. Adv. Mater. 28, 7915 (2016).

J. Bauer, A. Schroer, R. Schwaiger, I. Tesari, C. Lange, L. Valdevit, and O. Kraft: Push-to-pull tensile testing of ultra-strong nanoscale ceramic–polymer composites made by additive manufacturing. Extreme Mech. Lett. 3, 105 (2015).

H. Xu and D. Pasini: Structurally efficient three-dimensional metamaterials with controllable thermal expansion. Sci. Rep. 6, 34924 (2016).

T.A. Schaedler, A.J. Jacobsen, A. Torrents, A.E. Sorensen, J. Lian, J.R. Greer, L. Valdevit, and W.B. Carter: Ultralight metallic microlattices. Science 334, 962 (2011).

A. Rafsanjani, A. Akbarzadeh, and D. Pasini: Snapping mechanical metamaterials under tension. Adv. Mater. 27, 5931 (2015).

L. Wang, J. Lau, E.L. Thomas, and M.C. Boyce: Co-continuous composite materials for stiffness, strength, and energy dissipation. Adv. Mater. 23, 1524 (2011).

O. Al-Ketan, R.K.A. Al-Rub, and R. Rowshan: Mechanical properties of a new type of architected interpenetrating phase composite materials. Adv. Mater. Technol. 2, 1600235 (2017).

J.T. Overvelde, J.C. Weaver, C. Hoberman, and K. Bertoldi: Rational design of reconfigurable prismatic architected materials. Nature 541, 347 (2017).

M.F. Ashby, T. Evans, N.A. Fleck, J. Hutchinson, H. Wadley, and L. Gibson: Metal Foams: A Design Guide (Elsevier, Oxford, United Kingdom, 2000).

P. Heinl, L. Müller, C. Körner, R.F. Singer, and F.A. Müller: Cellular Ti–6Al–4V structures with interconnected macro porosity for bone implants fabricated by selective electron beam melting. Acta Biomater. 4, 1536 (2008).

D.K. Pattanayak, A. Fukuda, T. Matsushita, M. Takemoto, S. Fujibayashi, K. Sasaki, N. Nishida, T. Nakamura, and T. Kokubo: Bioactive Ti metal analogous to human cancellous bone: Fabrication by selective laser melting and chemical treatments. Acta Biomater. 7, 1398 (2011).

T. Freyman, I. Yannas, and L. Gibson: Cellular materials as porous scaffolds for tissue engineering. Prog. Mater. Sci. 46, 273 (2001).

P. Jain and T. Pradeep: Potential of silver nanoparticle-coated polyurethane foam as an antibacterial water filter. Biotechnol. Bioeng. 90, 59 (2005).

A. Montillet, J. Comiti, and J. Legrand: Application of metallic foams in electrochemical reactors of filter-press type part I: Flow characterization. J. Appl. Electrochem. 23, 1045 (1993).

L. Giani, G. Groppi, and E. Tronconi: Mass-transfer characterization of metallic foams as supports for structured catalysts. Ind. Eng. Chem. Res. 44, 4993 (2005).

K. Boomsma, D. Poulikakos, and F. Zwick: Metal foams as compact high performance heat exchangers. Mech. Mater. 35, 1161 (2003).

T. Lu, H. Stone, and M. Ashby: Heat transfer in open-cell metal foams. Acta Mater. 46, 3619 (1998).

D.P. Haack, K.R. Butcher, T. Kim, and T. Lu: Novel lightweight metal foam heat exchangers. In Proceedings of 2001 ASME International Mechanical Engineering Congress and Exposition, November 11-16, 2001, New York, NY IMECE2001, (2001).

X. Zheng, H. Lee, T.H. Weisgraber, M. Shusteff, J. DeOtte, E.B. Duoss, J.D. Kuntz, M.M. Biener, Q. Ge, and J.A. Jackson: Ultralight, ultrastiff mechanical metamaterials. Science 344, 1373 (2014).

M. Rashed, M. Ashraf, R. Mines, and P.J. Hazell: Metallic microlattice materials: A current state of the art on manufacturing, mechanical properties and applications. Mater. Des. 95, 518 (2016).

L. Liu, P. Kamm, F. García-Moreno, J. Banhart, and D. Pasini: Elastic and failure response of imperfect three-dimensional metallic lattices: The role of geometric defects induced by selective laser melting. J. Mech. Phys. Solids 107, 160 (2017).

C. Yan, L. Hao, A. Hussein, S.L. Bubb, P. Young, and D. Raymont: Evaluation of light-weight AlSi10Mg periodic cellular lattice structures fabricated via direct metal laser sintering. J. Mater. Process. Technol. 214, 856 (2014).

C. Yan, L. Hao, A. Hussein, and P. Young: Ti–6Al–4V triply periodic minimal surface structures for bone implants fabricated via selective laser melting. J. Mech. Behav. Biomed. Mater. 51, 61 (2015).

C. Yan, L. Hao, A. Hussein, P. Young, and D. Raymont: Advanced lightweight 316L stainless steel cellular lattice structures fabricated via selective laser melting. Mater. Des. 55, 533 (2014).

H. Alsalla, L. Hao, and C. Smith: Fracture toughness and tensile strength of 316L stainless steel cellular lattice structures manufactured using the selective laser melting technique. Mater. Sci. Eng., A 669, 1 (2016).

F. Brenne, T. Niendorf, and H. Maier: Additively manufactured cellular structures: Impact of microstructure and local strains on the monotonic and cyclic behavior under uniaxial and bending load. J. Mater. Process. Technol. 213, 1558 (2013).

S. Sing, W. Yeong, F. Wiria, and B. Tay: Characterization of titanium lattice structures fabricated by selective laser melting using an adapted compressive test method. Exp. Mech. 56, 735 (2016).

O. Al-Ketan, A. Soliman, A.M. AlQubaisi, and R.K. Abu Al-Rub: Nature-inspired lightweight cellular co-continuous composites with architected periodic gyroidal structures. Adv. Eng. Mater., 1700549, doi: https://doi.org/10.1002/adem.201700549 (2017).

F. Bobbert, K. Lietaert, A. Eftekhari, B. Pouran, S. Ahmadi, H. Weinans, and A. Zadpoor: Additively manufactured metallic porous biomaterials based on minimal surfaces: A unique combination of topological, mechanical, and mass transport properties. Acta Biomater. 53 (Suppl. C), 572 (2017).

S. Rajagopalan and R.A. Robb: Schwarz meets schwann: Design and fabrication of biomorphic and durataxic tissue engineering scaffolds. Med. Image Anal. 10, 693 (2006).

S. Torquato and A. Donev: Minimal surfaces and multifunctionality. Proc. R. Soc. London, Ser. A 460, 1849 (2004).

D-J. Yoo: New paradigms in cellular material design and fabrication. Int. J. Precis. Eng. Manuf. 16, 2577 (2015).

Q. Feng, Q. Tang, Z. Liu, Y. Liu, and R. Setchi: An investigation of the mechanical properties of metallic lattice structures fabricated using selective laser melting. Proc. Inst. Mech. Eng., Part B, 0954405416668924, doi: https://doi.org/10.1177/0954405416668924 (2016).

X. Wang, S. Xu, S. Zhou, W. Xu, M. Leary, P. Choong, M. Qian, M. Brandt, and Y.M. Xie: Topological design and additive manufacturing of porous metals for bone scaffolds and orthopaedic implants: A review. Biomaterials 83, 127 (2016).

S. Giannitelli, D. Accoto, M. Trombetta, and A. Rainer: Current trends in the design of scaffolds for computer-aided tissue engineering. Acta Biomater. 10, 580 (2014).

S.M. Ahmadi, S.A. Yavari, R. Wauthle, B. Pouran, J. Schrooten, H. Weinans, and A.A. Zadpoor: Additively manufactured open-cell porous biomaterials made from six different space-filling unit cells: The mechanical and morphological properties. Materials 8, 1871 (2015).

V.S. Deshpande, N.A. Fleck, and M.F. Ashby: Effective properties of the octet-truss lattice material. J. Mech. Phys. Solids 49, 1747 (2001).

S. Arabnejad, R.B. Johnston, J.A. Pura, B. Singh, M. Tanzer, and D. Pasini: High-strength porous biomaterials for bone replacement: A strategy to assess the interplay between cell morphology, mechanical properties, bone ingrowth and manufacturing constraints. Acta Biomater. 30, 345 (2016).

S. McKown, Y. Shen, W. Brookes, C. Sutcliffe, W. Cantwell, G. Langdon, G. Nurick, and M. Theobald: The quasi-static and blast loading response of lattice structures. Int. J. Impact Eng. 35, 795 (2008).

L. Mullen, R.C. Stamp, W.K. Brooks, E. Jones, and C.J. Sutcliffe: Selective laser melting: A regular unit cell approach for the manufacture of porous, titanium, bone in-growth constructs, suitable for orthopedic applications. J. Biomed. Mater. Res., Part B 89, 325 (2009).

Y.H. Ha, R.A. Vaia, W.F. Lynn, J.P. Costantino, J. Shin, A.B. Smith, P.T. Matsudaira, and E.L. Thomas: Three-dimensional network photonic crystals via cyclic size reduction/infiltration of sea urchin exoskeleton. Adv. Mater. 16, 1091 (2004).

S.C. Kapfer, S.T. Hyde, K. Mecke, C.H. Arns, and G.E. Schröder-Turk: Minimal surface scaffold designs for tissue engineering. Biomaterials 32, 6875 (2011).

D. Yoo: New paradigms in hierarchical porous scaffold design for tissue engineering. Mater. Sci. Eng., C 33, 1759 (2013).

D.W. Abueidda, R. Abu Al-Rub, A.S. Dalaq, D-W. Lee, K.A. Khan, and I. Jasiuk: Effective conductivities and elastic moduli of novel foams with triply periodic minimal surfaces. Mech. Mater. 95, 102 (2016).

D.W. Abueidda, R. Abu Al-Rub, A.S. Dalaq, H.A. Younes, A.A. Al Ghaferi, and T.K. Shah: Electrical conductivity of 3D periodic architectured interpenetrating phase composites with carbon nanostructured-epoxy reinforcements. Compos. Sci. Technol. 118, 127 (2015).

D.W. Abueidda, M. Bakir, R.K.A. Al-Rub, J.S. Bergström, N.A. Sobh, and I. Jasiuk: Mechanical properties of 3D printed polymeric cellular materials with triply periodic minimal surface architectures. Mater. Des. 122, 255 (2017).

D.W. Abueidda, A.S. Dalaq, R. Abu Al-Rub, and H.A. Younes: Finite element predictions of effective multifunctional properties of interpenetrating phase composites with novel triply periodic solid shell architectured reinforcements. Int. J. Mech. Sci. 92, 80 (2015).

D.W. Abueidda, A.S. Dalaq, R.K.A. Al-Rub, and I. Jasiuk: Micromechanical finite element predictions of a reduced coefficient of thermal expansion for 3D periodic architectured interpenetrating phase composites. Compos. Struct. 133, 85 (2015).

O. Al-Ketan, M.A. Assad, and R.K. Abu Al-Rub: Mechanical properties of periodic interpenetrating phase composites with novel architected microstructures. Compos. Struct. 176, 9–19 (2017).

J. Kadkhodapour, H. Montazerian, A.C. Darabi, A. Zargarian, and S. Schmauder: The relationships between deformation mechanisms and mechanical properties of additively manufactured porous biomaterials. J. Mech. Behav. Biomed. Mater. 70, 28–42 (2016).

S.C. Han, J.W. Lee, and K. Kang: A new type of low density material: Shellular. Adv. Mater. 27, 5506 (2015).

I. Maskery, N.T. Aboulkhair, A. Aremu, C. Tuck, and I. Ashcroft: Compressive failure modes and energy absorption in additively manufactured double gyroid lattices. Addit. Manuf. 16, 24–29 (2017).

O. Elliott, S. Gray, M. McClay, B. Nassief, A. Nunnelley, E. Vogt, J. Ekong, K. Kardel, A. Khoshkhoo, and G. Proaño: Design and manufacturing of high surface area 3D-printed media for moving bed bioreactors for wastewater treatment. J. Contemp. Water Res. Educ. 160, 144 (2017).

T. Femmer, A.J. Kuehne, and M. Wessling: Estimation of the structure dependent performance of 3-D rapid prototyped membranes. Chem. Eng. J. 273, 438 (2015).

N. Sreedhar, N. Thomas, O. Al-Ketan, R. Rowshan, H. Hernandez, R.K. Abu Al-Rub, and H.A. Arafat: 3D printed feed spacers based on triply periodic minimal surfaces for flux enhancement and biofouling mitigation in RO and UF. Desalination 425, 12 (2018).

D. Cvijović and J. Klinowski: The computation of the triply periodic I-WP minimal surface. Chem. Phys. Lett. 226, 93 (1994).

K. Michielsen and J. Kole: Photonic band gaps in materials with triply periodic surfaces and related tubular structures. Phys. Rev. B 68, 115107 (2003).

S. Li: Boundary conditions for unit cells from periodic microstructures and their implications. Compos. Sci. Technol. 68, 1962 (2008).

A.S. Dalaq, D.W. Abueidda, R.K. Abu Al-Rub, and I.M. Jasiuk: Finite element prediction of effective elastic properties of interpenetrating phase composites with architectured 3D sheet reinforcements. Int. J. Solids Struct. 83, 169 (2016).

C. Wang, L. Feng, and I. Jasiuk: Scale and boundary conditions effects on the apparent elastic moduli of trabecular bone modeled as a periodic cellular solid. J. Biomech. Eng. 131, 121008 (2009).

S. Khaderi, V. Deshpande, and N. Fleck: The stiffness and strength of the gyroid lattice. Int. J. Solids Struct. 51, 3866 (2014).

D-W. Lee, K.A. Khan, and R.K. Abu Al-Rub: Stiffness and yield strength of architectured foams based on the Schwarz Primitive triply periodic minimal surface. Int. J. Plast. 95 (Suppl. C), 1 (2017).

A. Vigliotti, V.S. Deshpande, and D. Pasini: Non linear constitutive models for lattice materials. J. Mech. Phys. Solids 64, 44 (2014).

L. Valdevit, S.W. Godfrey, T.A. Schaedler, A.J. Jacobsen, and W.B. Carter: Compressive strength of hollow microlattices: Experimental characterization, modeling, and optimal design. J. Mater. Res. 28, 2461 (2013).

S. Van Bael, G. Kerckhofs, M. Moesen, G. Pyka, J. Schrooten, and J-P. Kruth: Micro-CT-based improvement of geometrical and mechanical controllability of selective laser melted Ti6Al4V porous structures. Mater. Sci. Eng., A 528, 7423 (2011).

Z.S. Bagheri, D. Melancon, L. Liu, R.B. Johnston, and D. Pasini: Compensation strategy to reduce geometry and mechanics mismatches in porous biomaterials built with Selective Laser Melting. J. Mech. Behav. Biomed. Mater. 70, 17 (2017).

R. Wauthle, B. Vrancken, B. Beynaerts, K. Jorissen, J. Schrooten, J-P. Kruth, and J. Van Humbeeck: Effects of build orientation and heat treatment on the microstructure and mechanical properties of selective laser melted Ti6Al4V lattice structures. Addit. Manuf. 5, 77 (2015).

E. Sallica-Leva, A. Jardini, and J. Fogagnolo: Microstructure and mechanical behavior of porous Ti–6Al–4V parts obtained by selective laser melting. J. Mech. Behav. Biomed. Mater. 26, 98 (2013).

C. Qiu, S. Yue, N.J. Adkins, M. Ward, H. Hassanin, P.D. Lee, P.J. Withers, and M.M. Attallah: Influence of processing conditions on strut structure and compressive properties of cellular lattice structures fabricated by selective laser melting. Mater. Sci. Eng., A 628, 188 (2015).

V. Deshpande, M. Ashby, and N. Fleck: Foam topology: Bending versus stretching dominated architectures. Acta Mater. 49, 1035 (2001).

J.C. Maxwell: L. on the calculation of the equilibrium and stiffness of frames. London, Edinburgh, and Dublin Philos. Mag. J. Sci. 27, 294 (1864).

M. Mazur, M. Leary, S. Sun, M. Vcelka, D. Shidid, and M. Brandt: Deformation and failure behaviour of Ti–6Al–4V lattice structures manufactured by selective laser melting (SLM). Int. J. Adv. Manuf. Technol. 84, 1391 (2016).

L.J. Gibson and M.F. Ashby: Cellular Solids: Structure and Properties (Cambridge University Press, Cambridge, United Kingdom, 1999).

A. Vigliotti and D. Pasini: Stiffness and strength of tridimensional periodic lattices. Comput. Methods Appl. Mech. Eng. 229, 27 (2012).

J. Kadkhodapour, H. Montazerian, A.C. Darabi, A. Anaraki, S. Ahmadi, A. Zadpoor, and S. Schmauder: Failure mechanisms of additively manufactured porous biomaterials: Effects of porosity and type of unit cell. J. Mech. Behav. Biomed. Mater. 50, 180 (2015).

K. Kempen, E. Yasa, L. Thijs, J-P. Kruth, and J. Van Humbeeck: Microstructure and mechanical properties of selective laser melted 18Ni-300 steel. Phys. Procedia 12, 255 (2011).

ACKNOWLEDGMENTS

The first and third authors acknowledge the financial support provided by Masdar Institute. The experimental parts were printed using Core Technology Platform resources at NYU Abu Dhabi. We thank Khulood Alawadi for assistance with 3D printing. The authors would also like to thank Alia Abu Ali for helping in designing the BCC lattice structures and Dr. Kamran Khan from Khalifa University of Science, Technology and Research for helping in testing the samples.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Al-Ketan, O., Abu Al-Rub, R.K. & Rowshan, R. The effect of architecture on the mechanical properties of cellular structures based on the IWP minimal surface. Journal of Materials Research 33, 343–359 (2018). https://doi.org/10.1557/jmr.2018.1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2018.1