Abstract

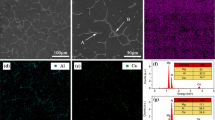

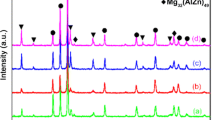

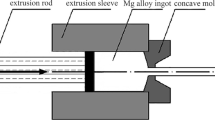

Hot extrusion experiments were conducted on Al–5.50Zn–2.35Mg–1.36Cu (wt%) alloy under various temperatures and extrusion speeds. Results indicated that dynamic recovery occurred at low temperature and then dynamic recrystallization was triggered at higher temperature or speed. High billet temperature reduced the grain size and increased the volume fraction of Al23CuFe4 and AlMgZn. When the extrusion speed was enhanced to 0.5 mm/s, the peak of MgZn2 phase diminished in the results of X-ray diffraction. The strong brass and S components appeared in all the extruded specimens. Texture intensity gradually decreased with increasing temperature and the fraction of texture components was also significantly affected by the extrusion parameters. The extruded alloy exhibited the highest ultimate tensile strength of 350.2 MPa at 480 °C and 0.5 mm/s and the best elongation of 16.78% at 520 °C and 0.1 mm/s. Moreover, the extrusion speed had more significant effects on the tensile properties than that of the temperature.

Similar content being viewed by others

References

L. Chen, G. Zhao, J. Yu, W. Zhang, and T. Wu: Analysis and porthole die design for a multi-hole extrusion process of a hollow, thin-walled aluminum profile. Int. J. Adv. Manuf. Technol. 74, 383 (2014).

W.L. Gao, J. Xu, J. Teng, and Z. Lu: Microstructure characteristics and mechanical properties of a 2A66 Al–Li alloy processed by continuous repetitive upsetting and extrusion. J. Mater. Res. 31, 2506 (2016).

L. Chen, G. Zhao, and J. Yu: Effects of ram velocity on pyramid die extrusion of hollow aluminum profile. Int. J. Adv. Manuf. Technol. 79, 2117 (2015).

P. Ma, Y. Jia, K.G. Prashanth, Z. Yu, C. Li, J. Zhao, S. Yang, and L. Huang: Effect of Si content on the microstructure and properties of Al–Si alloys fabricated using hot extrusion. J. Mater. Res. 32, 2210 (2017).

A. Moshkovich, I. Lapsker, Y. Feldman, and L. Rapoport: Severe plastic deformation of four FCC metals during friction under lubricated conditions. Wear 386, 49 (2017).

G. Chen, L. Chen, G. Zhao, C. Zhang, and W. Cui: Microstructure analysis of an Al–Zn–Mg alloy during porthole die extrusion based on modeling of constitutive equation and dynamic recrystallization. J. Alloys Compd. 710, 80 (2017).

Y.Q. Li, L. Chen, J.W. Tang, G.Q. Zhao, and C.S. Zhang: Effects of asymmetric feeder on microstructure and mechanical properties of high strength Al–Zn–Mg alloy by hot extrusion. J. Alloys Compd. 749, 293 (2018).

Y. Zhu, F. Bian, and C. Liu: Dynamic recovery and recrystallization mechanisms during ultrasonic spot welding of Al–Cu–Mg alloy. Mater. Charact. 132, 145 (2017).

L. Xie, Q. Lei, M. Wang, X. Sheng, and Z. Li: Effects of aging mechanisms on the exfoliation corrosion behavior of a spray deposited Al–Zn–Mg–Cu–Zr aluminum alloy. J. Mater. Res. 32, 1105 (2017).

J. Zhou, J. Duszczyk, and B.M. Korevaar: As-spray-deposited structure of an Al–20Si–5Fe Osprey preform and its development during subsequent processing. J. Mater. Sci. 26, 5275 (1991).

N. Alatorre, R.R. Ambriz, A. Amrouche, C. Garcia, and D. Jaramillo: Fatigue crack growth in Al–Zn–Mg (7075-T651) welds obtained by modified indirect and gas metal arc welding techniques. J. Mater. Process. Technol. 248, 207 (2017).

Y.N. Wu, H.C. Liao, Y.B. Liu, and K.X. Zhou: Dynamic precipitation of Mg2Si induced by temperature and strain during hot extrusion and its impact on microstructure and mechanical properties of near eutectic Al–Si–Mg–V alloy. Mater. Sci. Eng., A 614, 162 (2014).

Y.Q. Ma and L.H. Qi: Effect of extrusion temperature on the microstructure and tensile property of 2D-Cf/Al composites by liquid extrusion infiltration. Int. J. Adv. Manuf. Technol. 94, 1349 (2018).

A.E. Ragab, M.A. Taha, A.T. Abbas, E.A. Al Bahkali, E.A. El-Danaf, and M.F. Aly: Effect of extrusion temperature on the surface roughness of solid state recycled aluminum alloy 6061 chips during turning operation. Adv. Mech. Eng. 9, 1 (2017).

M. Jahedi, B. Mani, S. Shakoorian, E. Pourkhorshid, and M.H. Paydar: Deformation rate effect on the microstructure and mechanical properties of Al–SiCp composites consolidated by hot extrusion. Mater. Sci. Eng., A 556, 23 (2012).

F. Gagliardi, T. Citrea, G. Ambrogio, and L. Filice: Influence of the process setup on the microstructure and mechanical properties evolution in porthole die extrusion. Mater. Des. 60, 274 (2014).

J.Q. Yu, G.Q. Zhao, W.C. Cui, C.S. Zhang, and L. Chen: Microstructural evolution and mechanical properties of welding seams in aluminum alloy profiles extruded by a porthole die under different billet heating temperatures and extrusion speeds. J. Mater. Process. Technol. 247, 214 (2017).

T. Sakai, H. Miura, A. Goloborodko, and O. Sitdikov: Continuous dynamic recrystallization during the transient severe deformation of aluminum alloy 7475. Acta Mater. 57, 153 (2009).

R. Jamaati and M.R. Toroghinejad: Effect of stacking fault energy on deformation texture development of nanostructured materials produced by the ARB process. Mater. Sci. Eng., A 598, 263 (2014).

Y.Q. Ning, B.C. Xie, H.Q. Liang, H. Li, X.M. Yang, and H.Z. Guo: Dynamic softening behavior of TC18 titanium alloy during hot deformation. Mater. Des. 71, 68 (2015).

A. Galiyev, R. Kaibyshev, and G. Gottstein: Correlation of plastic deformation and dynamic recrystallization in magnesium alloy ZK60. Acta Mater. 49, 1199 (2001).

M. Ferry and N. Burhan: Microstructural evolution in a fine-grained Al–0.3 wt% Sc alloy produced by severe plastic deformation. Scr. Mater. 56, 525 (2007).

G. Chen, L. Chen, G. Zhao, and B. Lu: Investigation on longitudinal weld seams during porthole die extrusion process of high strength 7075 aluminum alloy. Int. J. Adv. Manuf. Technol. 5–8, 1897 (2017).

R.Z. Valiev and T.G. Langdon: Achieving exceptional grain refinement through severe plastic deformation: New approaches for improving the processing technology. Metall. Mater. Trans. A 42, 2942 (2011).

H. Yamagata, Y. Ohuchida, N. Saito, and M. Otsuka: Dynamic recrystallization and dynamic recovery of 99.99 mass% aluminum single crystal having [112] orientation. J. Mater. Sci. Lett. 20, 1947 (2001).

S.W. Xu, N. Matsumoto, S. Kamado, T. Honma, and Y. Kojima: Dynamic microstructural changes in Mg–9Al–1Zn alloy during hot compression. Scr. Mater. 61, 249 (2009).

S.W. Xu, S. Kamado, and T. Honma: Recrystallization mechanism and the relationship between grain size and Zener–Hollomon parameter of Mg–Al–Zn–Ca alloys during hot compression. Scr. Mater. 63, 293 (2010).

M. Murayama, Z. Horita, and K. Hono: Microstructure of two-phase Al–1.7 at.% Cu alloy deformed by equal-channel angular pressing. Acta Mater. 49, 21 (2001).

P.K. Rout, M.M. Ghosh, and K.S. Ghosh: Microstructural, mechanical and electrochemical behaviour of a 7017 Al–Zn–Mg alloy of different tempers. Mater. Charact. 107, 454 (2015).

G.J. Chen, L. Chen, G.Q. Zhao, and C.S. Zhang: Microstructure evolution during solution treatment of extruded Al–Zn–Mg profile containing a longitudinal weld seam. J. Alloys Compd. 729, 210 (2017).

S. Wang, M.P. Wang, C. Chen, Z. Xiao, Y.L. Jia, Z. Li, and Z.X. Wang: Orientation dependence of the dislocation microstructure in compressed body-centered cubic molybdenum. Mater. Charact. 91, 10 (2014).

L. Chen, J.X. Zhang, G.Q. Zhao, Z.S. Wang, and C.S. Zhang: Microstructure and mechanical properties of Mg–Al–Zn alloy extruded by porthole die with different initial billets. Mater. Sci. Eng., A 718, 390 (2018).

A.M. Kliauga, R.E. Bolmaro, and M. Ferrante: The evolution of texture in an equal channel pressed aluminum AA1050. Mater. Sci. Eng., A 623, 22 (2015).

W.C. Liu, X.Y. Kong, M.B. Chen, J. Li, H. Yuan, and Q.X. Yang: Texture development in a pseudo cross-rolled AA 3105 aluminum alloy. Mater. Sci. Eng., A 516, 263 (2009).

D.M. Kirch, E. Jannot, L.A. Barrales-Mora, D.A. Molodov, and G. Gottstein: Inclination dependence of grain boundary energy and its impact on the faceting and kinetics of tilt grain boundaries in aluminum. Acta Mater. 56, 4998 (2008).

Q.H. Wang, B. Jiang, Y.F. Chai, B. Liu, S.X. Ma, J. Xu, and F.S. Pan: Tailoring the textures and mechanical properties of AZ31 alloy sheets using asymmetric composite extrusion. Mater. Sci. Eng., A 673, 606 (2016).

R. Narayanasamy, R. Ravindran, K. Manonmani, and J. Satheesh: A crystallographic texture perspective formability investigation of aluminium 5052 alloy sheets at various annealing temperatures. Mater. Des. 30, 1804 (2009).

Acknowledgments

The authors would like to acknowledge the financial support from National Natural Science Foundation of China (U1708251, 51735008), Key Research and Development Program of Shandong Province (2018GGX103041), and Young Scholars Program of Shandong University (2018WLJH26).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, L., Li, Y., Tang, J. et al. Investigation on microstructure and mechanical properties of Al–5.50Zn–2.35Mg–1.36Cu alloy fabricated by hot extrusion process. Journal of Materials Research 34, 3151–3162 (2019). https://doi.org/10.1557/jmr.2019.268

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2019.268