Abstract

It is of the uttermost interest to understand the mechanical performance and deformation mechanisms contributing to small-scale plasticity of materials in micro/nanoelectromechanical systems at their service temperatures, which are usually above room temperature. In recent years, high-temperature nanoindentation experiments have emerged as a reliable approach to characterize the deformation behavior of materials at the nano and submicron scale. In this review, we highlight the role of the temperature in nanoindentation response of a wide variety of materials, with a particular focus on the thermally-activated deformation mechanisms in crystalline and non-crystalline materials under the indenter, e.g., dislocation processes, shear transformation zone, and phase transformations. A brief survey of the temperature-dependent nanoindentation elastic modulus, hardness, and creep behavior of materials is also provided. We also discuss experimental methods for correctly measuring the mechanical properties of materials at high temperatures.

Similar content being viewed by others

References

W.K. Liu, E.G. Karpov, and H.S. Park: Nano mechanics and materials: theory, multiscale methods and applications (John Wiley & Sons, England, 2006).

B.D. Beake and J.F. Smith: High-temperature nanoindentation testing of fused silica and other materials. Philos. Mag. A 82, 2179–2186 (2002).

J. Wheeler, D. Armstrong, W. Heinz, and R. Schwaiger: High temperature nanoindentation: the state of the art and future challenges. Current Opinion Solid State Mater. Sci. 19, 354–366 (2015).

W. Kang, M. Merrill, and J.M. Wheeler: In situ thermomechanical testing methods for micro/nano-scale materials. Nanoscale 9, 2666–2688 (2017).

J.C. Trenkle, C.E. Packard, and C.A. Schuh: Hot nanoindentation in inert environments. Rev. Sci. Instrum. 81, 073901–073914 (2010).

J. Wheeler, P. Brodard, and J. Michler: Elevated temperature, in situ indentation with calibrated contact temperatures. Philos. Mag. 92, 3128–3141 (2012).

J. Wheeler and J. Michler: Elevated temperature, nano-mechanical testing in situ in the scanning electron microscope. Rev. Sci. Instrum. 84, 045103–045118 (2013).

C.A. Schuh, C.E. Packard, and A.C. Lund: Nanoindentation and contactmode imaging at high temperatures. J.Mater. Res. 21, 725–736 (2006).

C.E. Packard, J.M. Wheeler, J.C. Trenkle, and C.A. Schuh: Nanoindentation: high temperature. In Reference Module in Materials Science and Materials Engineering (Elsevier, 2016).

C. Schuh, J. Mason, A. Lund, and A. Hodge. High temperature nanoindentation for the study of flow defects. in MRS Proceedings (Cambridge University Press, 2004).

M.C. Wingert, J. Zheng, S. Kwon, and R. Chen: Thermal transport in amorphous materials: a review. Semicond. Sci. Technol. 31, 113003 (2016).

P.E. Hopkins, M. Ding, and J. Poon: Contributions of electron and phonon transport to the thermal conductivity of GdFeCo and TbFeCo amorphous rare-earth transition-metal alloys. J.Appl. Phys. 111, 103533 (2012).

S.Z. Chavoshi, S. Goel, and X. Luo: Molecular dynamics simulation investigation on the plastic flow behaviour of silicon during nanometric cutting. Model. Simul. Mater. Sci. Eng. 24, 015002 (2015).

S.Z. Chavoshi, S. Goel, and X. Luo: Influence of temperature on the anisotropic cutting behaviour of single crystal silicon: a molecular dynamics simulation investigation. J.Manuf. Process. 23, 201–210 (2016).

S.Z. Chavoshi and X. Luo: An atomistic simulation investigation on chip related phenomena in nanometric cutting of single crystal silicon at elevated temperatures. Comput. Mater. Sci. 113, 1–10 (2016).

S.Z. Chavoshi and X. Luo: Atomic-scale characterization of occurring phenomena during hot nanometric cutting of single crystal 3C-SiC. RSC Adv. 6, 71409–71424 (2016).

S.Z. Chavoshi, S. Xu, and X. Luo: Dislocation-mediated plasticity in silicon during nanometric cutting: a molecular dynamics simulation study. Mater. Sci. Semicond. Process. 51, 60–70 (2016).

S.Z. Chavoshi and X. Luo: Molecular dynamics simulation study of deformation mechanisms in 3C-SiC during nanometric cutting at elevated temperatures. Mater. Sci. Eng.: A 654, 400–417 (2016).

H. Mathur, V. Maier-Kiener, and S. Korte-Kerzel: Deformation in the γ-Mg 17 Al 12 phase at 25-278° C. Acta Mater. 113, 221–229 (2016).

L. Shen, Y. Wu, S. Wang, and Z. Chen: Creep behavior of Sn-Bi solder alloys at elevated temperatures studied by nanoindentation. J.Mater. Sci., Mater. Electron. 28, 4114–4124 (2017).

X. Kong, X. Kong, F. Sun, F. Sun, M. Yang, M. Yang, Y. Liu, and Y. Liu: High temperature creep properties of low-Ag Cu/Sn-Ag-Cu-Bi-Ni/Cu solder joints by nanoindentation method. Solder. Surf. Mount Technol. 28, 167–174 (2016).

K. Rajulapati, M. Biener, J. Biener, and A. Hodge: Temperature dependence of the plastic flow behavior of tantalum. Philos. Mag. Lett. 90, 35–42 (2010).

O. Franke, J. Alcalá, R. Dalmau, Z.C. Duan, J. Biener, M. Biener, and A. M. Hodge: Incipient plasticity of single-crystal tantalum as a function of temperature and orientation. Philos. Mag. 95, 1866–1877 (2015).

G.I. Taylor: The mechanism of plastic deformation of crystals. Part I. Theoretical. Proceedings of the Royal Society of London. Ser. A, Containing Papers Math. Phys. Character 145, 362–387 (1934).

K. Durst, B. Backes, O. Franke, and M. Göken: Indentation size effect in metallic materials: modeling strength from pop-in to macroscopic hardness using geometrically necessary dislocations. Acta Mater. 54, 2547–2555 (2006).

W.D. Nix and H. Gao: Indentation size effects in crystalline materials: a law for strain gradient plasticity. J. Mech. Phys. Solids 46, 411–425 (1998).

X. Qiu, Y. Huang, W. Nix, K. Hwang, and H. Gao: Effect of intrinsic lattice resistance in strain gradient plasticity. Acta Mater. 49, 3949–3958 (2001).

A.C. Lund, A.M. Hodge, and C.A. Schuh: Incipient plasticity during nanoindentation at elevated temperatures. Appl. Phys. Lett. 85, 1362–1364 (2004).

C. Schuh, J. Mason, and A. Lund: Quantitative insight into dislocation nucleation from high-temperature nanoindentation experiments. Nat. Mater. 4, 617–621 (2005).

J. Mason, A. Lund, and C. Schuh: Determining the activation energy and volume for the onset of plasticity during nanoindentation. Phys. Rev. B 73, 054102 (2006).

M. Haghshenas, V. Bhakhri, R. Oviasuyi, and R. Klassen: Effect of temperature and strain rate on the mechanisms of indentation deformation of magnesium. MRS Commun. 5, 513–518 (2015).

I.-C. Choi, C. Brandl, and R. Schwaiger: Thermally activated dislocation plasticity in body-centered cubic chromium studied by high-temperature nanoindentation. Acta Mater. 140, 107–115 (2017).

M.-M. Primorac, M.D. Abad, P. Hosemann, M. Kreuzeder, V. Maier, and D. Kiener: Elevated temperature mechanical properties of novel ultra-fine grained Cu-Nb composites. Mater. Sci. Eng.: A 625, 296–302 (2015).

V. Maier, K. Durst, J. Mueller, B. Backes, H.W. Höppel, and M. Göken: Nanoindentation strain-rate jump tests for determining the local strainrate sensitivity in nanocrystalline Ni and ultrafine-grained Al. J.Mater. Res. 26, 1421–1430 (2011).

J. Wheeler, V. Maier, K. Durst, M. Göken, and J. Michler: Activation parameters for deformation of ultrafine-grained aluminium as determined by indentation strain rate jumps at elevated temperature. Mater. Sci. Eng.: A 585, 108–113 (2013).

N. Li, L. Liu, K. Chan, Q. Chen, and J. Pan: Deformation behavior and indentation size effect of Au 49 Ag 5.5 Pd 2.3 Cu 26.9 Si 16.3 bulk metallic glass at elevated temperatures. Intermetallics 17, 227–230 (2009).

B. Yang, J. Wadsworth, and T.-G. Nieh: Thermal activation in Au-based bulk metallic glass characterized by high-temperature nanoindentation. Appl. Phys. Lett. 90, 061911 (2007).

A. Argon: Plastic deformation in metallic glasses. Acta Metall. 27, 47–58 (1979).

A. Argon and L.T. Shi: Development of visco-plastic deformation in metallic glasses. Acta Metall. 31, 499–507 (1983).

R. Zallen: The physics of amorphous solids (John Wiley & Sons, Weinheim, 2008).

C.A. Schuh, A.C. Lund, and T. Nieh: New regime of homogeneous flow in the deformation map of metallic glasses: elevated temperature nanoindentation experiments and mechanistic modeling. Acta Mater. 52, 5879–5891 (2004).

C.E. Packard, J. Schroers, and C.A. Schuh: In situ measurements of surface tension-driven shape recovery in a metallic glass. Scr. Mater. 60, 1145–1148 (2009).

D.L. Henann and L. Anand: Surface tension-driven shape-recovery of micro/nanometer-scale surface features in a Pt 57.5 Ni 5.3 Cu 14.7 P22.5 metallic glass in the supercooled liquid region: a numerical modeling capability. J.Mech. Phys. Solids 58, 1947–1962 (2010).

G. Kumar and J. Schroers: Write and erase mechanisms for bulk metallic glass. Appl. Phys. Lett. 92, 031901 (2008).

J. Wheeler, R. Raghavan, and J. Michler: In situ SEM indentation of a Zr-based bulk metallic glass at elevated temperatures. Mater. Sci. Eng.: A 528, 8750–8756 (2011).

A. Bhattacharyya, G. Singh, K.E. Prasad, R. Narasimhan, and U. Ramamurty: On the strain rate sensitivity of plastic flow in metallic glasses. Mater. Sci. Eng.: A 625, 245–251 (2015).

S. Minomura and H. Drickamer: Pressure induced phase transitions in silicon, germanium and some III-V compounds. J.Phys. Chem. Solids 23, 451–456 (1962).

D. Ge, V. Domnich, and Y. Gogotsi: High-resolution transmission electron microscopy study of metastable silicon phases produced by nanoindentation. J.Appl. Phys. 93, 2418–2423 (2003).

R. Piltz, J. Maclean, S. Clark, G. Ackland, P. Hatton, and J. Crain: Structure and properties of silicon XII: a complex tetrahedrally bonded phase. Phys. Rev. B 52, 4072–4085 (1995).

S. Ruffell, J. Bradby, and J. Williams: High pressure crystalline phase formation during nanoindentation: amorphous versus crystalline silicon. Appl. Phys. Lett. 89, 091919 (2006).

S.Z. Chavoshi, S.C. Gallo, H. Dong, and X. Luo: High temperature nanoscratching of single crystal silicon under reduced oxygen condition. Mater. Sci. Eng.: A 684, 385–393 (2017).

S. Bhuyan, J. Bradby, S. Ruffell, B. Haberl, C. Saint, J. Williams, and P. Munroe: Phase stability of silicon during indentation at elevated temperature: evidence for a direct transformation from metallic Si-II to diamond cubic Si-I. MRS Commun. 2, 9–12 (2012).

S. Ruffell, J. Bradby, J. Williams, D. Munoz-Paniagua, S. Tadayyon, L. Coatsworth, and P. Norton: Nanoindentation-induced phase transformations in silicon at elevated temperatures. Nanotechnology 20, 135603–135608 (2009).

M. Kiran, B. Haberl, J. Williams, and J. Bradby: Temperature dependent deformation mechanisms in pure amorphous silicon. J.Appl. Phys. 115, 113511 (2014).

R.K. Singh, P. Munroe, and M. Hoffman: Effect of temperature on metastable phases induced in silicon during nanoindentation. J.Mater. Res. 23, 245–249 (2008).

V. Domnich, Y. Aratyn, W.M. Kriven, and Y. Gogotsi: Temperature dependence of silicon hardness: experimental evidence of phase transformations. Rev. Adv. Mater. Sci. 17, 33–41 (2008).

M. Kiran, T. Tran, L. Smillie, B. Haberl, D. Subianto, J. Williams, and J. Bradby: Temperature-dependent mechanical deformation of silicon at the nanoscale: phase transformation versus defect propagation. J.Appl. Phys. 117, 205901 (2015).

L. Vandeperre, F. Giuliani, S. Lloyd, and W. Clegg: The hardness of silicon and germanium. Acta Mater. 55, 6307–6315 (2007).

S. Xiao and P. Pirouz: On diamond-hexagonal germanium. J.Mater. Res. 7, 1406–1412 (1992).

C.S. Menoni, J.Z. Hu, and I.L. Spain: Germanium at high pressures. Phys. Rev. B 34, 362 (1986).

X. Huang, J. Nohava, B. Zhang, and A. Ramirez: Nanoindentation of NiTi shape memory thin films at elevated temperatures. Int. J. Smart Nano Mater. 2, 39–49 (2011).

X.-G. Ma and K. Komvopoulos: In situ transmission electron microscopy and nanoindentation studies of phase transformation and pseudoelasticity of shape-memory titanium-nickel films. J.Mater. Res. 20, 1808–1813 (2005).

K. Komvopoulos and X.-G. Ma: Pseudoelasticity of martensitic titaniumnickel shape-memory films studied by in situ heating nanoindentation and transmission electron microscopy. Appl. Phys. Lett. 87, 263108 (2005).

Y. Li, X. Fang, S. Lu, Q. Yu, G. Hou, and X. Feng: Effects of creep and oxidation on reduced modulus in high-temperature nanoindentation. Mater. Sci. Eng.: A 678, 65–71 (2016).

G. Feng and A. Ngan: Effects of creep and thermal drift on modulus measurement using depth-sensing indentation. J.Mater. Res. 17, 660–668 (2002).

J.A. Rogers, A.A. Maznev, M.J. Banet, and K.A. Nelson: Optical generation and characterization of acoustic waves in thin films: fundamentals and applications. Annu. Rev. Mater. Sci. 30, 117–157 (2000).

C.E. Beck, F. Hofmann, J.K. Eliason, A.A. Maznev, K.A. Nelson, and D. E. Armstrong: Correcting for contact area changes in nanoindentation using surface acoustic waves. Scr. Mater. 128, 83–86 (2017).

N. Fujisawa and M.V. Swain: On the indentation contact area of a creeping solid during constant-strain-rate loading by a sharp indenter. J.Mater. Res. 22, 893–899 (2007).

B. Haberl, L.B.B. Aji, J. Williams, and J.E. Bradby: The indentation hardness of silicon measured by instrumented indentation: what does it mean? J. Mater. Res. 27, 3066–3072 (2012).

T. Tsui and G. Pharr: Substrate effects on nanoindentation mechanical property measurement of soft films on hard substrates. J.Mater. Res. 14, 292–301 (1999).

J.S.-L. Gibson, S.G. Roberts, and D.E. Armstrong: High temperature indentation of helium-implanted tungsten. Mater. Sci. Eng.: A 625, 380–384 (2015).

A. Harris, B. Beake, D. Armstrong, and M. Davies: Development of high temperature nanoindentation methodology and its application in the nanoindentation of polycrystalline tungsten in vacuum to 950° C. Exp. Mech. 57, 1115–1126 (2017).

M.R. de Figueiredo, M.D. Abad, A.J. Harris, C. Czettl, C. Mitterer, and P. Hosemann: Nanoindentation of chemical-vapor deposited Al 2 O 3 hard coatings at elevated temperatures. Thin Solid Films 578, 20–24 (2015).

R. Ctvrtlik, M.S. Al-Haik, and V. Kulikovsky: Mechanical properties of amorphous silicon carbonitride thin films at elevated temperatures. J. Mater. Sci. 50, 1553–1564 (2015).

N. Rohbeck, D. Tsivoulas, I.P. Shapiro, P. Xiao, S. Knol, J.-M. Escleine, and M. Perez: In-situ nanoindentation of irradiated silicon carbide in TRISO particle fuel up to 500° C. J. Nucl. Mater. 465, 692–694 (2015).

E. Broitman, L. Tengdelius, U.D. Hangen, J. Lu, L. Hultman, and H. Högberg: High-temperature nanoindentation of epitaxial ZrB 2 thin films. Scr. Mater. 124, 117–120 (2016).

J.-Y. Lu, H. Ren, D.-M. Deng, Y. Wang, K.J. Chen, K.-M. Lau, and T.-Y. Zhang: Thermally activated pop-in and indentation size effects in GaN films. J.Phys. D: Appl. Phys. 45, 085301 (2012).

T. Nieh, C. Iwamoto, Y. Ikuhara, K. Lee, and Y. Chung: Comparative studies of crystallization of a bulk Zr-Al-Ti-Cu-Ni amorphous alloy. Intermetallics 12, 1183–1189 (2004).

V. Marques, C. Johnston, and P. Grant: Nanomechanical characterization of Sn-Ag-Cu/Cu joints—Part 1: young’s modulus, hardness and deformation mechanisms as a function of temperature. Acta Mater. 61, 2460–2470 (2013).

V. Marques, B. Wunderle, C. Johnston, and P. Grant: Nanomechanical characterization of Sn-Ag-Cu/Cu joints—Part 2: Nanoindentation creep and its relationship with uniaxial creep as a function of temperature. Acta Mater. 61, 2471–2480 (2013).

J.S.-L. Gibson, S. Schröders, C. Zehnder, and S. Korte-Kerzel: On extracting mechanical properties from nanoindentation at temperatures up to 1000° C. Extreme Mech. Lett. 17, 43–49 (2017).

A. Prasitthipayong, S. Vachhani, S. Tumey, A. Minor, and P. Hosemann: Indentation size effect in unirradiated and ion-irradiated 800H steel at high temperatures. Acta Mater. 144, 896–904 (2018).

A.M. Wood and T. Clyne: Measurement and modelling of the nanoindentation response of shape memory alloys. Acta Mater. 54, 5607–5615 (2006).

V. Maier, A. Hohenwarter, R. Pippan, and D. Kiener: Thermally activated deformation processes in body-centered cubic Cr-How microstructure influences strain-rate sensitivity. Scr. Mater. 106, 42–45 (2015).

A. Leitner, V. Maier-Kiener, J. Jeong, M. Abad, P. Hosemann, S. Oh, and D. Kiener: Interface dominated mechanical properties of ultra-fine grained and nanoporous Au at elevated temperatures. Acta Mater. 121, 104–116 (2016).

M. Kreuzeder, M.-D. Abad, M.-M. Primorac, P. Hosemann, V. Maier, and D. Kiener: Fabrication and thermo-mechanical behavior of ultra-fine porous copper. J. Mater. Sci. 50, 634–643 (2015).

J.R. Trelewicz and C.A. Schuh: Hot nanoindentation of nanocrystalline Ni-W alloys. Scr. Mater. 61, 1056–1059 (2009).

V. Maier-Kiener, B. Schuh, E.P. George, H. Clemens, and A. Hohenwarter: Insights into the deformation behavior of the CrMnFeCoNi high-entropy alloy revealed by elevated temperature nanoindentation. J.Mater. Res. 32, 2658–2667 (2017).

K. Kormout, P. Ghosh, V. Maier-Kiener, and R. Pippan: Deformation mechanisms during severe plastic deformation of a Cu Ag composite. J.Alloys Compd. 695, 2285–2294 (2017).

Q. Wu, Y. Meng, K. Concha, S. Wang, Y. Li, L. Ma, and S. Fu: Influence of temperature and humidity on nano-mechanical properties of cellulose nanocrystal films made from switchgrass and cotton. Ind. Crops Prod. 48, 28–35 (2013).

J. Milhans, D. Li, M. Khaleel, X. Sun, M.S. Al-Haik, A. Harris, and H. Garmestani: Mechanical properties of solid oxide fuel cell glass-ceramic seal at high temperatures. J.Power Sources 196, 5599–5603 (2011).

U. Hangen, C.L. Chen, and A. Richter: Mechanical characterization of PM2000 oxide-dispersion-strengthened alloy by high temperature nanoindentation. Adv. Eng. Mater. 17, 1683–1690 (2015).

Y. Li, X. Fang, B. Xia, and X. Feng: In situ measurement of oxidation evolution at elevated temperature by nanoindentation. Scr. Mater. 103, 61–64 (2015).

Y. Li, S. Feng, W. Wu, and F. Li: Temperature dependent mechanical property of PZT film: an investigation by nanoindentation. PLoS ONE 10, e0116478 (2015).

S. Koch, M.D. Abad, S. Renhart, H. Antrekowitsch, and P. Hosemann: A high temperature nanoindentation study of Al-Cu wrought alloy. Mater. Sci. Eng.: A 644, 218–224 (2015).

F. Gao, H. Nishikawa, T. Takemoto, and J. Qu: Mechanical properties versus temperature relation of individual phases in Sn-3.0 Ag-0.5 Cu leadfree solder alloy. Microelectron. Reliab. 49, 296–302 (2009).

R. Seltzer, J.K. Kim, and Y.W. Mai: Elevated temperature nanoindentation behaviour of polyamide 6. Polym. Int. 60, 1753–1761 (2011).

J. Fulcher, Y. Lu, G. Tandon, and D. Foster: Thermomechanical characterization of shape memory polymers using high temperature nanoindentation. Polym. Test. 29, 544–552 (2010).

M. Hinz, A. Kleiner, S. Hild, O. Marti, U. Dürig, B. Gotsmann, U. Drechsler, T. Albrecht, and P. Vettiger: Temperature dependent nano indentation of thin polymer films with the scanning force microscope. Eur. Polym. J. 40, 957–964 (2004).

S. Sills, H. Fong, C. Buenviaje, M. Sarikaya, and R.M. Overney: Thermal transition measurements of polymer thin films by modulated nanoindentation. J. Appl. Phys. 98, 014302 (2005).

P.S. Phani and W. Oliver: A direct comparison of high temperature nanoindentation creep and uniaxial creep measurements for commercial purity aluminum. Acta Mater. 111, 31–38 (2016).

G. Cheng, K.S. Choi, X. Hu, and X. Sun: Determining individual phase properties in a multi-phase Q&P steel using multi-scale indentation tests. Mater. Sci. Eng.: A 652, 384–395 (2016).

J. Kadkhodapour, S. Schmauder, D. Raabe, S. Ziaei-Rad, U. Weber, and M. Calcagnotto: Experimental and numerical study on geometrically necessary dislocations and non-homogeneous mechanical properties of the ferrite phase in dual phase steels. Acta Mater. 59, 4387–4394 (2011).

T.-H. Ahn, C.-S. Oh, D. Kim, K. Oh, H. Bei, E.P. George, and H. Han: Investigation of strain-induced martensitic transformation in metastable austenite using nanoindentation. Scr. Mater. 63, 540–543 (2010).

B. He, M. Huang, Z. Liang, A. Ngan, H. Luo, J. Shi, W. Cao, and H. Dong: Nanoindentation investigation on the mechanical stability of individual austenite grains in a medium-Mn transformation-induced plasticity steel. Scr. Mater. 69, 215–218 (2013).

K.R. Gadelrab, G. Li, M. Chiesa, and T. Souier: Local characterization of austenite and ferrite phases in duplex stainless steel using MFM and nanoindentation. J.Mater. Res. 27, 1573–1579 (2012).

J. Wheeler, C. Niederberger, C. Tessarek, S. Christiansen, and J. Michler: Extraction of plasticity parameters of GaN with high temperature, in situ micro-compression. Int. J. Plast. 40, 140–151 (2013).

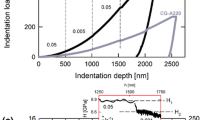

W.C. Oliver and G.M. Pharr: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564–1583 (1992).

J. Field and M. Swain: A simple predictive model for spherical indentation. J. Mater. Res. 8, 297–306 (1993).

Acknowledgments

SZC would like to express his sincere gratitude for the financial support from the BIAM-Imperial Centre for Materials Characterization, Processing, and Modeling at Imperial College London. The work of SX was supported in part by the Elings Prize Fellowship in Science offered by the California NanoSystems Institute (CNSI) on the UC Santa Barbara campus.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chavoshi, S.Z., Xu, S. Temperature-dependent nanoindentation response of materials. MRS Communications 8, 15–28 (2018). https://doi.org/10.1557/mrc.2018.19

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/mrc.2018.19