Abstract

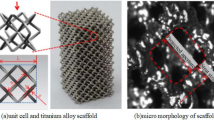

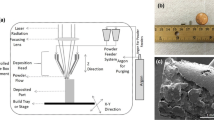

The long-term success of an orthopedic implant largely depends on the extent of its osseointegration in the surrounding bone. During recent decades, there have been several attempts to develop porous structures and coatings in order to maximize the bone ingrowth on prosthesis surfaces. Innovative additive manufacturing technologies, such as electron beam melting (EBM), which are based upon building components by adding layers of material rather than by removing material from a raw shape, can provide a breakthrough solution, both to overcome the major limitations of the actual technologies and to significantly enhance the performance of porous scaffolds. This article reviews the latest developments in EBM technology applied to the preparation of highly biocompatible porous materials such as Trabecular Titanium and the production of orthopedic prostheses with enhanced characteristics.

Similar content being viewed by others

References

R.J. Friedman, J. Black, J.O. Galante, J.J. Jacobs, H.B. Skinner, J. Bone Joint Surg. Am. 75 (7), 1086 (1993).

K. Anselme, Biomaterials 21 (7), 667 (2000).

P. Heinl, L. Muller, C. Korner, R.F. Singer, F.A. Muller, Acta Biomater. 4 (5), 1536 (2008).

M. Baleani, M. Viceconti, A. Toni, Artif. Organs 24 (4), 296 (2000).

A. Christensen, A. Lippincott, R. Kircher, Proc. Conf. MEDDEV, Palm Desert, 2007, (ASM International ed., Materials Park, OH) p. 129.

V.M. Goldberg, Clin. Orthop. Relat. Res. 319, 122 (1995).

K.H. Frosch, F. Barvencik, V. Viereck, C.H. Lohmann, K. Dresing, J. Breme, E. Brunner, K.M. Sturmen, J. Biomed. Mater. Res. 68A (2), 325 (2004).

V. Karageorgiou, D. Kaplan, Biomaterials 26, 2775 (2005).

S.D. Cook, K.A. Thomas, J.F. Kay, Clin. Orthop. 265, 280 (1991).

X. Li, C. Wang, W. Zhang, Y. Li, Mater. Lett. 63 (3–4), 403 (2009).

P.M. Bonutti, R. Pivec, K. Issa, B.H. Kapadia, S. Banerjee, S.F. Harwin, M.A. Mont, T.W. Bauer, Orthopedics 36 (8), 417 (2013).

H.R. Bloch, S. Burelli, D. Devine, D. Arens, Proc. Conf. 13th EFORT, (Berlin, 2012), p. 85.

M. Mour, D. Das, T. Winkler, E. Hoenig, G. Mielke, M.M. Morlock, A.F. Schilling, Appl. Mater. 3, 2947 (2010).

O. Cansizoglu, D. Harrysson, D. Cormier, H. West, T. Mahale, Mater. Sci. Eng. 492 (1–2), 468 (2008).

J.C.S. Pires, A.F.B. Braga, P.R. Mei, Sol. Energy Mater. Sol. Cells 79 (3), 347 (2003).

A. Hershcovitch, Nucl. Instrum. Methods Phys. Res. B 241 (1–4), 854 (2005).

Q.F. Guan, H. Zou, A.M. Wu, S.Z. Hao, J.X. Zou, Y. Qin, C. Dong, Q.Y. Zhang, Surf. Coat. Technol. 196 (1–3), 145 (2005).

S. Kalpakjian, S.R. Schmid, Manufacturing Engineering and Technology (Prentice Hall, Upper Saddle River, NJ, 2009).

M. Niinomi, Mater. Sci. Eng. 243 (1–2), 231 (1998).

S. Schneider, I. Egry, I. Seyhan, Int. J. Thermophys. 23 (5), 1241 (2002).

P. Dalla Pria, M. Pressacco, E. Veronesi, Sphera Med. J. 7, 4 (2008).

E. Marin, S. Fusi, M. Pressacco, L. Paussa, L. Fedrizzi, J. Mech. Behav. Biomed. Mater. 3 (5), 790 (2010).

E. Marin, M. Pressacco, S. Fusi, A. Lanzutti, S. Turchet, L. Fedrizzi, Mater. Sci. Eng. C 33, 2648 (2013).

D. Devine, D. Arens, S. Burelli, H.R. Bloch, L. Boure, J. Bone Joint Surg. 94B, 201 (2010).

B.R. Levine, S. Sporer, R.A. Poggie, C.J. Della Valle, J.J. Jacobs, Biomaterials 27 (27), 4671 (2006).

L.D. Zardiackas, D.E. Parsell, L.D. Dillon, D.W. Mitchell, L.A. Nunnery, R. Poggie, J. Biomed. Mater. Res. 58 (2), 180 (2001).

R.R. Boyer, Metals Handbook 9th ed. ( ASM International, Materials Park, OH, 1985).

G.R. Yoder, L.A. Cooley, T.W. Crooker, Eng. Fract. Mech. 11 (4), 805 (1979).

G.R. Yoder, D. Eylon, Metall. Mater. Trans. A 10, 1808 (1979).

S.Y. Sung, Y.J. Kim, Mater. Sci. Eng. A 405 (1–2), 173 (2005).

ISO 13314, International Standardization Organization, 2011.

M.F. Ashby, A. Evans, N.A. Fleck, L.J. Gibson, J.W. Hutchinson, H.N.G. Wadley, Metal Foams—A Design Guide (Butterworth-Heinemann, Oxford, UK, 2000).

J.J. Callaghan, A.G. Rosenberg, H.E. Rubash, in The Adult Hip 2nd ed. (Lippincott Williams & Wilkins, Philadelphia, PA, 2007), vol. 1.

ASTM F1147, ASTM International, 2005.

L. Gilmour, B. Jones, J. Dickinson, Proc. Conf. MEDDEV, Memphis, 2009, (ASM International ed., Materials Park, OH), pp. 129–132.

G. Gastaldi, A. Asti, M.F. Scaffino, L. Visai, E. Saino, A.M. Cometa, F. Benazzo, J. Biomed. Mater. Res. A 94 (3), 790 (2010).

A. Asti, G. Gastaldi, R. Dorati, E. Saino, B. Conti, L. Visai, F. Benazzo, Bioinorg. Chem. Appl. 83, 176 (2010).

V. Sollazzo, A. Plamieri, L. Massari, F. Clarinci, J. Orthop. Traumatol. 13 (1), 107 (2012).

A. Bistolfi, L. Ravera, E. Graziano, G. Collo, D. Malino, A. Giordano, G. Massazza, Minerva Orthop. Traumatol. 65, 199 (2014).

L. Perticarini, L. Piovani, S.M.P. Rossi, A. Combi, A. Padolino, F. Benazzo, J. Orthop. Traumatol. 12 (Suppl. 1), 147 (2011).

L. Perticarini, M. Ghiara, T. Lamberti, F.M. Benazzo, Bone Joint J. 95B (Suppl. 34), 479 (2013).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Regis, M., Marin, E., Fedrizzi, L. et al. Additive manufacturing of Trabecular Titanium orthopedic implants. MRS Bulletin 40, 137–144 (2015). https://doi.org/10.1557/mrs.2015.1

Published:

Issue Date:

DOI: https://doi.org/10.1557/mrs.2015.1