Abstract

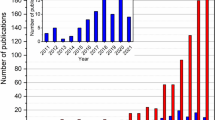

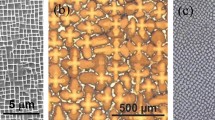

There is increasing interest in the use of additive manufacturing (AM) for Ni-based superalloys due to their various applications in the aerospace and power-generation sectors. Ni-based superalloys are known to have a complex chemistry, with over a dozen alloying elements in most alloys, enabling them to achieve outstanding high-temperature mechanical performance as well as oxidation resistance when processed using conventional routes (e.g., casting and forging). Nonetheless, this complex chemistry results in the formation of various phases that could affect their processability using AM, resulting in cracking. Furthermore, due to the directional solidification and rapid cooling associated with AM processes, the alloys experience significant anisotropy due to the epitaxially grown microstructure, as well as the residual stresses that can sometimes be difficult to mitigate using thermal postprocessing techniques. This article highlights the outstanding issues in Ni-based superalloys AM processing, with special emphasis on defect formation mechanisms, process optimization, and residual stress development.

Similar content being viewed by others

References

M.J. Donachie, S.J. Donachie, Superalloys: A Technical Guide, 2nd ed. (ASM International, Materials Park, OH, 2002).

M. Durand-Charre, The Microstructure of Superalloys (Gordon and Breach Science Publishers, Amsterdam, 1997).

R. Schafrik, R. Sprague, Key Eng. Mater. 380, 113 (2008).

R.C. Reed, The Superalloys: Fundamentals and Applications (Cambridge University Press, New York, 2006).

M.B. Henderson, D. Arrell, R. Larsson, M. Heobel, G. Marchant, Sci. Technol. Weld. Joining 9, 13 (2004).

G.A. Young, T.E. Capobianco, M.A. Penik, B.W. Morris, J.J. McGee, Weld. J. 87, 31 (2008).

E.A. Ott, J. Groh, H. Sizek, Proc. Sixth Int. Special Emphasis Symp. Superalloys 718, 625, 706 and Derivatives, E.A. Loria, Ed. (The Minerals, Metals and Materials Society, Warrendale, PA, 2006), pp. 35–46.

N.J. Harrison, I. Todd, K. Mumtaz, Acta Mater. 94, 59 (2015).

P. Withers, H. Bhadeshia, Mater. Sci. Technol. 17, 355 (2001).

P. Mercelis, J.-P. Kruth, Rapid Prototyp. J. 12, 254 (2006).

P. Withers, H. Bhadeshia, Mater. Sci. Technol. 17, 366 (2001).

A. Pinkerton, J. Shackleton, R. Moat, L. Li, P. Withers, M. Preuss, J. Allen, P. Hilton, R. Folwell, Proc. 24th Int. Congr. Applic. Lasers Electro-optics (ICALEO) (Laser Institute of America, Orlando, FL, 2005), pp. 601–610.

D.D. Gu, W. Meiners, K. Wissenbach, R. Poprawe, Int. Mater. Rev. 57, 133 (2012).

B. Vrancken, R. Wauthlé, J.-P. Kruth, J. Van Humbeeck, Proc. Solid Freeform Fabr. Symp. (The University of Texas at Austin, Austin, TX, 2013), pp. 1–15.

R. Moat, A. Pinkerton, L. Li, P. Withers, M. Preuss, Mater. Sci. Eng. A 528, 2288 (2011).

M. Zhong, H. Sun, W. Liu, X. Zhu, J. He, Scr. Mater. 53, 159 (2005).

L.L. Parimi, M.M. Attallah, J. Gebelin, R.C. Reed, Proc. Superalloys 2012, E.S. Huron, R.C. Reed, M.C. Hardy, M.J. Mills, R.E. Montero, P.D. Portella, J. Telesman, Eds. (Wiley, New York, 2012), pp. 509–519.

N. Klingbeil, J. Beuth, R. Chin, C. Amon, Int. J. Mech. Sci. 44, 57 (2002).

P. Prabhakar, W. Sames, R. Dehoff, S. Babu, Addit. Manuf. 7, 83 (2015).

C. Casavola, S. Campanelli, C. Pappalettere, J. Strain Anal. Eng. Des. 44, 93 (2009).

M. Griffith, M. Schlienger, L. Harwell, M. Oliver, M. Baldwin, M. Ensz, M. Essien, J. Brooks, C. Robino, E.J. Smugeresky, Mater. Des. 20, 107 (1999).

F. Neugebauer, N. Keller, X. Hongxiao, C. Kober, V. Ploshikhin, Proc. Fraunhofer Direct Digital Manuf. Conf. (Fraunhofer Verlag, Stuttgart, Germany, 2014).

P. Rangaswamy, M. Griffith, M. Prime, T. Holden, R. Rogge, J. Edwards, R. Sebring, Mater. Sci. Eng. A 399, 72 (2005).

A. Vasinonta, J.L. Beuth, M.L. Griffith, J. Manuf. Sci. Eng. 123, 615 (2001).

P. Aggarangsi, J.L. Beuth, M. Griffith, Proc. Solid Freeform Fabr. Symp. (The University of Texas at Austin, Austin, TX, 2003), pp. 196–207.

J. Beuth, N. Klingbeil, JOM 53, 36 (2001).

K. Dai, L. Shaw, Rapid Prototyp. J. 8, 270 (2002).

L. Wang, S.D. Felicelli, P. Pratt, Mater. Sci. Eng. A 496, 234 (2008).

M. Labudovic, D. Hu, R. Kovacevic, J. Mater. Sci. 38, 35 (2003).

M.F. Zaeh, G. Branner, Prod. Eng. 4, 35 (2010).

R. Moat, A.J. Pinkerton, D.J. Hughes, L. Li, P.J. Withers, M. Preuss, “Stress Distributions in Multilayer Laser Deposited Waspaloy Parts Measured Using Neutron Diffraction, Proc. 25th Int. Congr. on Applic. Lasers Electro-optics (ICALEO) (Laser Institute of America, Orlando, FL, 2007).

X. Song, M. Xie, F. Hofmann, T. Illston, T. Connolley, C. Reinhard, R. Atwood, L. Connor, M. Drakopoulos, L. Frampton, Int. J. Mater. Form. 8, 245 (2015).

A.S.C. D’Oliveira, P.S.C. da Silva, R.M. Vilar, Surf. Coat. Technol. 153, 203 (2002).

S. Zekovic, R. Dwivedi, R. Kovacevic, Proc. Solid Freeform Fabr. (The University of Texas at Austin, Austin, TX, 2005).

N. Shamsaei, A. Yadollahi, L. Bian, S.M. Thompson, Addit. Manuf. 8, 12 (2015).

A. Gåård, P. Krakhmalev, J. Bergström, J. Alloys Compd. 421, 166 (2006).

A. Nickel, D. Barnett, F. Prinz, Mater. Sci. Eng. A 317, 59 (2001).

S. Finnie, W. Cheng, I. Finnie, J.-M. Drezet, M. Gremaud, J. Eng. Mater. Technol. 125, 302 (2003).

R.A. Kupkovits, R.W. Neu, Int. J. Fatigue 32, 1330 (2010).

L.N. Carter, X. Wang, N. Read, R. Khan, M. Aristizabal, K. Essa, M.M. Attallah, Mater. Sci. Technol. 32, 657 (2015).

H. Qi, M. Azer, A. Ritter, Metall. Mater. Trans. A 40, 2410 (2009).

L.N. Carter, K. Essa, M.M. Attallah, Rapid Prototyp. J. 21, 423 (2015).

M. Ramsperger, R. Singer, C. Körner, Metall. Mater. Trans. A 47, 1469 (2016).

F. Wang, X. Wu, D. Clark, Mater. Sci Technol. 21, 344 (2011).

Q. Jia, D. Gu, J. Alloys Compd. 585, 713 (2014).

K.A. Mumtaz, P. Erasenthiran, N. Hopkinson, J. Mater. Process. Technol. 195, 77 (2008).

S. Das, T.P. Fuesting, G. Danyo, L.E. Brown, J.J. Beaman, D.L. Bourell, Mater. Des. 21, 63 (2000).

P.S. Wei, S.C. Kou, in Advances in Multiphase Flow and Heat Transfer, L. Cheng, Ed. (Bentham Science Publishers, online, 2009), vol. 1, pp. 213–232.

M. Cloots, P.J. Uggowitzer, K. Wegener, Mater. Des. 89, 770 (2016).

H.E. Helmer, C. Körner, R.F. Singer, J. Mater. Res. 29, 1987 (2014).

L. Carter, M. Attallah, R. Reed, Proc. Superalloys 2012, E.S. Huron, R.C. Reed, M.C. Hardy, M.J. Mills, R.E Montero, P.D. Portella, J. Telesman, Eds. (Wiley, New York, 2012) pp. 577–586.

C. Cross, in Hot Cracking Phenomena in Welds, T. Böllinghaus, H. Herold, Eds. (Springer, Berlin, 2005), chap. 1, pp. 3–18.

D. Dye, O. Hunziker, R.C. Reed, Acta Mater. 49, 683 (2001).

M.T. Rush, P.A. Colegrove, Z. Zhang, D. Broad, J. Mater. Process. Technol. 212, 188 (2012).

Y.-L. Tsai, S.-F. Wang, H.-Y. Bor, Y.-F. Hsu, Mater. Sci. Eng. A 607, 294 (2014).

D. Heydari, A.S. Fard, A. Bakhshi, J.M. Drezet, J. Mater. Process. Technol. 214, 681 (2013).

L.N. Carter, C. Martin, P.J. Withers, M.M. Attallah, J. Alloys Compd. 615, 338 (2014).

G. Young, T. Capobianco, M. Penik, B. Morris, J. McGee, Weld. J. 87, 31 (2008).

M.L. Collins, J.C. Lippold, Weld. J. 82, 288S (2003).

M.R. Collins, A. Ramirez, J.C. Lippold, Weld. J. 82 (12), 348S (2003).

M. Collins, A. Ramirez, J. Lippold, Weld. J. 83, 39 (2004).

J. Lippold, Welding Metallurgy and Weldability (Wiley, Hoboken, NJ, 2015).

G. Bi, A. Gasser, Phys. Procedia 12, 402 (2011).

S. Das, Adv. Eng. Mater. 5, 701 (2003).

L.L. Parimi, G. Ravi, D. Clark, M.M. Attallah, Mater. Charact. 89, 102 (2014).

F. Liu., X. Lin, G.L. Yang, M.H. Song, J. Chen, W.D. Huang, Opt. Laser Technol. 43, 208 (2011).

T. Vilaro, C. Colin, J.D. Bartout, L. Naze, M. Sennour, Mater. Sci. Eng. A 534, 446 (2012).

K.N. Amato, S.M. Gaytan, L.E. Murr, E. Martinez, P.W. Shindo, J. Hernandez, S. Collins, F. Medina, Acta Mater. 60, 2229 (2012).

P.L. Blackwell, J. Mater. Process. Technol. 170, 240 (2005).

E. Chlebus, K. Gruber, B. Kuźnicka, J. Kurzac, T. Kurzynowski, Mater. Sci. Eng. A 639, 647 (2015).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Attallah, M.M., Jennings, R., Wang, X. et al. Additive manufacturing of Ni-based superalloys: The outstanding issues. MRS Bulletin 41, 758–764 (2016). https://doi.org/10.1557/mrs.2016.211

Published:

Issue Date:

DOI: https://doi.org/10.1557/mrs.2016.211