Abstract

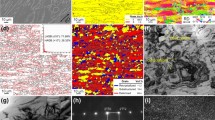

In this work, influence of heating temperature and cooling rate on microstructure and mechanical properties of a Ti–6Al–1V–4Mo–Si alloy was investigated. The samples were heated to β (1020 °C) and α + β (950 °C and 850 °C) phase field followed by furnace cooling, air cooling and oil quenching. Basketweave morphology was witnessed for samples furnace cooled from β phase field, while Widmanstatten microstructure was observed for most air-cooled samples. For samples oil quenched from β phase field, HCP martensite (αʹ) was formed, while for samples heated in α + β phase field, lamellar α with α′ was observed. Oil quenching from the β phase field resulted in high strength and low elongation. The strength decreased and elongation increased with reduction in the heating temperature. Highest elongation (~ 16%) was obtained for samples heated to 850 °C followed by furnace cooling. The elastic modulus displayed a wide range of values (70–150 GPa) depending on the processing conditions.

Graphic abstract

Similar content being viewed by others

References

R.J. Contieri, M. Zanotello, R. Caram, Recrystallization and grain growth in highly cold worked CP-Titanium. Mater. Sci. Eng. A 527(16–17), 3994 (2010)

I. Weiss, S.L. Semiatin, Thermomechanical processing of beta titanium alloys—an overview. Mater. Sci. Eng. 243, 46 (1998)

D. Xue, Y. Jiao, W. He, X. Shen, Y. Gao, L. Wang, Investigations into the improvement of the mechanical properties of Ti-5Al-4Mo-4Cr-2Sn-2Zr titanium alloy by using low energy laser peening without coating. Materials (Basel) 13(6), 1 (2020)

G. Lutjering, J.C. Williams, Titanium (Springer, Berlin, 2007).

S. Acharya, P. Gupta, K. Chatterjee, S. Suwas, Microstructure, texture and mechanical properties after cold working and annealing in a biomedical Ti-Nb-Ta alloy. Mater. Sci. Forum 941, 2465 (2018)

S. Bahl, P. Shreyas, M.A. Trishul, S. Suwas, K. Chatterjee, Enhancing the mechanical and biological performance of a metallic biomaterial for orthopedic applications through changes in the surface oxide layer by nanocrystalline surface modification. Nanoscale 7(17), 7704 (2015)

S. Roy, S. Suwas, S. Tamirisakandala, R. Srinivasan, D.B. Miracle, Processing response of boron modified Ti-6A1-4V alloy in (α+β) working regime, in 138th TMS Annual Meeting and Exhibition, vol. 3, p. 63 (2009)

R. Sabban, S. Bahl, K. Chatterjee, S. Suwas, Globularization using heat treatment in additively manufactured Ti-6Al-4V for high strength and toughness. Acta Mater. 162, 239 (2019)

I. Weiss, S.L. Semiatin, Thermomechanical processing of alpha titanium alloys—an overview. Mater. Sci. Eng. 263, 243 (1999)

S.L. Semiatin, The Thermomechanical processing of alpha/beta titanium alloys. JOM 49(33–39), 6 (1996)

G. Louarn, L. Salou, A. Hoornaert, P. Layrolle, Nanostructured surface coatings for titanium alloy implants. J. Mater. Res. 34(11), 1892 (2019)

J.O. Peters, G. Lutjering, Comparison of the fatigue and fracture of α + β and β titanium alloys. Metall. Mater. Trans. A 32A, 2805 (2001)

H. Jiang, P. Dong, S. Zeng, B. Wu, Effects of recrystallization on microstructure and texture evolution of cold-rolled Ti-6Al-4V alloy. J. Mater. Eng. Perform. 25, 1931 (2016)

M. Yamada, An overview on the development of titanium alloys for non-aerospace application in Japan. Mater. Sci. Eng. 213, 8 (1996)

T.W. Duerig, G.T. Terlinde, J.C. Williams, Phase transformations and tensile properties Of Ti-10V-2 Fe-3Al. Mater. Trans. 11(1980), 1987 (1987)

T. Ahmed, H.J. Rack, Phase transformations during cooling in α+β titanium alloys. Mater. Sci. Eng. 243, 206 (1998)

R. Ding, Z.X. Guo, A. Wilson, Microstructural evolution of a Ti-6Al-4V alloy during thermomechanical processing. Mater. Sci. Eng. A 327(2), 233 (2002)

X. Ma, F. Li, J. Li, J. Cao, P. Li, J. Dong, Effect of heat treatment on the microstructure and micro-mechanical behavior of quenched Ti-6Al-4V alloy. J. Mater. Eng. Perform. (2015). https://doi.org/10.1007/s11665-015-1682-z

N. Saunders, Modelling of phase equilibria in Ti-alloys, in Proc. 6th World Conference on Titanium (Les Editions de Physique, Paris, 1996), pp. 2167–2176

S. Malinov, Z. Guo, W. Sha, A. Wilson, Differential scanning calorimetry study and computer modeling of β ⇒ α phase transformation in a Ti-6Al-4V alloy. Metall. Mater. Trans. A 32, 879–887 (2001)

J.R. Patel, M. Cohen, Criterion for the action of applied stress in the martensitic transformation. Acta Metall. 1(5), 531 (1953)

J. Xu, W. Zeng, Y. Zhao, X. Sun, Z. Du, Influence of cooling rate following heat treatment on microstructure and phase transformation for a two-phase alloy. J. Alloys Compd. 688, 301 (2016)

N. Davari, A. Rostami, S.M. Abbasi, Effects of annealing temperature and quenching medium on microstructure, mechanical properties as well as fatigue behavior of Ti-6Al- crossmark 4V alloy. Mater. Sci. Eng. A 683, 1 (2017)

T. Grosdidier, C. Roubaud, M.J. Philippe, Y. Combres, The deformation mechanisms in the β-metastable β-cez titanium alloy. Scr. Mater. 36(1), 21 (1997)

A. Gupta, R.K. Khatirkar, A. Kumar, M.S. Parihar, Investigations on the effect of heating temperature and cooling rate on evolution of microstructure in an α + β titanium alloy. J. Mater. Res. 33(8), 946 (2018)

G. Lu, Influence of processing on microstructure and mechanical properties of (α+β) titanium alloys. Mater. Sci. Eng. A 243, 32 (1998)

R. Filip, K. Kubiak, W. Ziaja, J. Sieniawski, The effect of microstructure on the mechanical properties of two-phase titanium alloys. J. Mater. Process. Technol. 133, 84 (2003)

J. Gil, P. Ginebra, M. Manero, A. Planell, Formation of α-Widmanstatten structure: effects of grain size and cooling rate on the Widmanstatten morphologies and on the mechanical properties in Ti-6Al-4V alloy. J. Alloys Compd. 329, 142 (2001)

S. Zhu, H. Yang, L.G. Guo, X.G. Fan, Effect of cooling rate on microstructure evolution during α/β heat treatment of TA15 titanium alloy. Mater. Charact. 70, 101 (2012)

J.R. Wood, P.A. Russo, M.F. Welter, E.M. Crist, Thermomechanical processing and heat treatment of Ti–6Al–2Sn–2Zr–2Cr–2Mo–Si for structural applications. Mater. Sci. Eng. A 243, 109 (1998)

N. Poondla, T.S. Srivatsan, A. Patnaik, M. Petraroli, A study of the microstructure and hardness of two titanium alloys: commercially pure and Ti–6Al–4V. J. Alloys Compd. 486, 162 (2009)

A.K. Nag, K.V.U. Praveen, V. Singh, Effect of heat treatment on tensile behaviour of Ti–6Al–5Zr–0.5Mo–0.25Si alloy. Bull. Mater. Sci. 29(2), 147 (2006)

P. Barriobero-vila, J. Gussone, J. Haubrich, S. Sandloebes, J. Cesar, P. Cloetens, N. Schell, G. Requena, J. Cesar, Inducing stable α+β microstructures during selective laser melting of Ti-6Al-4V using intensified intrinsic heat treatments. Materials 10(3), 268 (2018)

P. Pototzky, H.J. Maier, H. Christ, Thermomechanical fatigue behavior of the high-temperature titanium alloy IMI 834. Metall. Mater. Trans. A 29, 2995–3004 (1998)

S. El-Hadad, M. Nady, W. Khalifa, A. Shash, Influence of heat treatment conditions on the mechanical properties of Ti–6Al–4V alloy. Can. Metall. Q. 57(2), 186 (2018)

M. Chang, C. Luo, M. Huang, High-temperature microstructural characteristics of a novel biomedical titanium alloy. J. Alloys Compd. 499(2), 171 (2010)

H. Fujii, Strengthening of α + β titanium alloys by thermomechanical processing. Mater. Sci. Eng. A 243(1–2), 103 (1998)

J.M. Manero, F.J. Gil, J.A. Planell, Deformation mechanisms of Ti-6Al-4V alloy with a martensitic microstructure subjected to oligocyclic fatigue. Acta Mater. 48(13), 3353 (2000)

P.W. Peng, K.L. Ou, C.Y. Chao, Y.N. Pan, C.H. Wang, Research of microstructure and mechanical behavior on duplex (α + β) Ti-4.8Al-2.5Mo-1.4V alloy. J. Alloys Compd. 490(1–2), 661 (2010)

A.K. Singh, C. Ramachandra, M. Tavafoghi, V. Singh, Microstructure of FL-solution-treated, quenched and aged. J. Alloys Compd. 179, 125 (1992)

Y. Ohmori, K. Nakai, H. Ohtsubo, M. Tsunofuri, Formation of Widmanstatten α structure in Ti64. Mater. Trans. 35(238), 4 (1994)

B.G. Yuan, C.F. Li, H.P. Yu, D.L. Sun, Influence of hydrogen content on tensile and compressive properties of Ti–6Al–4V alloy at room temperature Influence of hydrogen content on tensile and compressive properties of Ti–6Al–4V alloy at room temperature. Mater. Sci. Eng. A 527(16–17), 4185 (2010)

H. Matsumoto, K. Kodaira, K. Sato, T.J. Konno, A. Chiba, Microstructure and mechanical properties of α′ martensite type Ti alloys deformed under the α′ processing. Mater. Trans. 50(12), 2744 (2009)

Y. Chen, C. Yang, C. Fan, Y. Zhuo, S. Lin, C. Chen, Microstructure evolution mechanism and mechanical properties of TC11-TC17 dual alloy after annealing treatment. J. Alloys Compd. 842, 155874 (2020)

J. Dong, F. Li, C. Wang, Micromechanical behavior study of α phase with different morphologies of Ti-6Al-4V alloy by microindentation. Mater. Sci. Eng. A 580, 105 (2013)

S.L. Semiatin, J.C. Soper, I.M. Sukonnik, Grain growth in a conventional titanium alloy during rapid, continuous heat treatment. Scr. Metall. Mater. 30(7), 951 (1994)

S. Mironov, M. Murzinova, S. Zherebtsov, G.A. Salishchev, S.L. Semiatin, Microstructure evolution during warm working of Ti-6Al-4V with a colony-α microstructure. Acta Mater. 57(8), 2470 (2009)

S.V. Zherebtsov, M.A. Murzinova, M.V. Klimova, G.A. Salishchev, A.A. Popov, S.L. Semiatin, Microstructure evolution during warm working of Ti-5Al-5Mo-5V-1Cr-1Fe at 600 and 800°C. Mater. Sci. Eng. A 563, 168 (2013)

X. Ye, Z.T.H. Tse, G. Tang, Y. Geng, G. Song, Influence of electropulsing globularization on the microstructure and mechanical properties of Ti-6Al-4V alloy strip with lamellar microstructure. Mater. Sci. Eng. A 622, 1 (2015)

M. Meng, X.G. Fan, H. Yang, L.G. Guo, M. Zhan, P.F. Gao, Precipitation of secondary alpha in competition with epitaxial growth of primary alpha in two-phase titanium alloys. J. Alloys Compd. 714, 294 (2017)

L. Mora, C. Quesne, R. Peoelle, Relationships among thermomechanical treatments, microstructure, and tensile properties of a near beta-titanium alloy: β-CEZ: Part II. Relationships between thermomechanical treatments and tensile properties. J. Mater. Res. 11(1), 89 (1996)

C. Servant, C. Quesne, T. Baudin, R. Penelle, Contribution to the analysis of the α/β interface in some titanium alloys. J. Mater. Res. 6(5), 987 (1991)

A. Lenain, N. Clément, M. Véron, P.J. Jacques, Characterization of the α phase nucleation in a two-phase metastable β titanium alloy. J. Mater. Eng. Perform. 14(6), 722 (2005)

T. Furuhara, A.M. Dalley, H.I. Aaronson, Interfacial structure of grain boundary α allotriomorphs in a hypoeutectoid Ti-Cr alloy. Scr. Metall. 22(9), 1509 (1988)

G.B. Olson, M. Cohen, A mechanism for the strain-induced martensitic transformations. J. Less Common Met. 28, 107 (1972)

G.B. Olson, M. Cohen, A general mechanism of martensitic nucleation: Part II. FCC → BCC and other martensitic transformations. Metall. Trans. A 7(11), 1905 (1976)

P.C. Maxwell, A. Goldberg, J.C. Shyne, Stress-assisted and strain-induced martensites in FE-NI-C alloys. Metall. Trans. 5(6), 1305 (1974)

R. Armstrong, I. Codd, R.M. Douthwaite, N.J. Petch, The plastic deformation of polycrystalline aggregates. Philos. Mag. 7(73), 45 (1962)

S.L. Semiatin, T.R. Bieler, The effect of alpha platelet thickness on plastic flow during hot working of Ti–6Al–4V with a transformed microstructure. Acta Mater. 49, 3565 (2001)

P. Majumdar, S.B. Singh, M. Chakraborty, The role of heat treatment on microstructure and mechanical properties of Ti-13Zr-13Nb alloy for biomedical load bearing applications. J. Mech. Behav. Biomed. Mater. 4(7), 1132 (2011)

W.F. Ho, C.P. Ju, J.H. Chern Lin, Structure and properties of cast binary Ti-Mo alloys. Biomaterials 20(22), 2115 (1999)

Y.T. Lee, G. Welsch, Young’s modulus and damping of Ti6Al4V alloy as a function of heat treatment and oxygen concentration. Mater. Sci. Eng. A 128(1), 77 (1990)

Z. Guo, S. Malinov, W. Sha, Modelling beta transus temperature of titanium alloys using artificial neural network. Comput. Mater. Sci. 32, 1 (2005)

W. Baldwin, in Metallography and Microstructures, vol. 9 (ASM International, 2018)

Analysis Version 7.2. User Manual (TexSEM Laboratories Inc., Draper, 2013).

M.D. Abràmoff, P.J. Magalhães, S.J. Ram, Image processing with imageJ. Biophotonics Int. 11(7), 36 (2004)

ASTM E8/E8M-16ae1, Standard Test Methods for Tension Testing of Metallic Materials (ASTM International, West Conshohocken, PA, 2016). www.astm.org

Acknowledgments

The authors would like to thank The Director, VNIT Nagpur for providing the necessary facilities and constant encouragement to publish this paper. The authors would also like to acknowledge the use of ‘National Facility of Texture & OIM’ (a DST-IRPHA facility), IIT Bombay for EBBSD measurements. One of the authors, RKK, wishes to acknowledge Science and Engineering Research Board (SERB) for financial assistance to carry out this work (Grant No. EEQ/2016/000408).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mahadule, D., Khatirkar, R.K., Gupta, A. et al. Effect of heating temperature and cooling rate on the microstructure and mechanical properties of a Mo-rich two phase α + β titanium alloy. Journal of Materials Research 36, 751–763 (2021). https://doi.org/10.1557/s43578-020-00100-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-020-00100-6