Abstract

Utilisation of steel fibre reinforced concrete (SFRC) for designing structural members requires knowledge of the post-cracking tensile response. This paper reviews the experimental characterisation tests and subsequent analysis commonly used for determining the post-cracking tensile properties of SFRC. The experimental program supporting this investigation comprised five different SFRC mixes with fibre volumes ranging from 0.75 to 1.25% used to fabricate a set of characterisation specimens for uniaxial tension tests, notched beam tests and round panel tests carried out in parallel with an extensive experimental program on large scale beams. Characterisation test results allowed a comparison between direct stress–crack opening measurements and the stress–crack openings retrieved from the inverse analysis of bending tests. Discrepancies in post-cracking tensile results obtained with the three types of tests are analyzed and related mainly to test configurations, the presence of a predefined crack, support conditions, fibre orientation, and cracked surface size. Results obtained using material characterisations are then applied to the reproduction of the structural behaviour of large scale beams, documented in a companion paper.

Similar content being viewed by others

Abbreviations

- b :

-

Width of the specimen

- E c :

-

Young modulus

- E UT :

-

Area under σ–w curve for uniaxial test

- E bending :

-

Area under σ–w curve for bending test

- f cr :

-

Tensile strength

- h :

-

Height of the member

- L :

-

Length between support

- L r :

-

Reference length (geometric parameter)

- M :

-

Bending moment

- P :

-

Load

- r :

-

Radius between support of the round panel

- R :

-

Radius of the round panel

- V :

-

Coefficient of variation

- t :

-

Student’s factor

- w :

-

Crack width

- w max :

-

Maximum crack opening for design

- w t :

-

Crack opening in Appendix 1

- z :

-

Crack depth

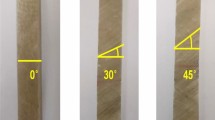

- α :

-

Cracked depth ratio

- δ :

-

Deflection

- δ max :

-

Maximum deflection

- Δ:

-

δ/δ max

- ε :

-

Strain

- ε max :

-

Maximum strain

- θ :

-

Crack angle

- γ :

-

Reliability coefficient

- ν :

-

Poisson’s coefficient

- σ :

-

Stress

- σ c :

-

Compression stress

- σ ch :

-

Characteristic stress

- σ f :

-

Post-cracking stress

- \( \bar{\sigma } \) :

-

Average stress

References

Serna P, Arango S, Ribeiro T, Nunez AM, Garcia-Taengua E (2009) Structural cast-in-place SFRC: technology, control criteria and recent applications in Spain. Mater Struct 42:1233–1246

Moffatt K, Massicotte B (2004) Design of continuous SFRC bridge decks for serviceability criteria. In: Proceeding of the sixth RILEM symposium of fibre-reinforced concrete, Varrena, Italia, 20–22 September 2004, pp 1173–1182

Destrée X (2004) Structural application of steel fibre as only reinforcing in free suspended elevated slabs: conditions—design—examples. In: Sixth RILEM symposium of fibre-reinforced concrete, Varenna, Italy, 20–22 September 2004, pp 1073–1082

Massicotte B, Bischoff PH (2000) Fibre reinforced concrete: a structural perspective. In: Proceeding of the fifth RILEM symposium of fibre-reinforced concrete, Lyon, France, 13–15 September 2000, pp 193–202

Walraven JC (2009) High performance fiber reinforced concrete: progress in knowledge and design codes. Mater Struct 42:1247–1260

RILEM (2001) RILEM TC 162-TDF: test and design methods for steel fiber reinforced concrete: uni-axial tension test for steel fiber reinforced concrete. Mater Struct 34:3–6

EN14651 (2004) Test method for metallic fibered concrete—measuring the flexural tensile strength (limit of proportionality (LOP), residual). European Committee for Standardization, Brussels

ASTM C1550 (2008) Standard test method for flexural toughness of fiber-reinforced concrete (using centrally loaded round panel). ASTM, West Conshohocken, PA

RILEM (2003) RILEM TC 162-TDF—tests and design methods for steel fibre reinforced concrete: σ–ε design method—final recommendation. Mater Struct 36:560–567

Soranakom C, Mobasher B (2009) Flexural design of fiber-reinforced concrete. ACI Mater J 106(5):461–469

Tran VNG, Bernard ES, Beasley AJ (2005) Constitutive modeling of fiber reinforced shortcrete panels. J Eng Mech 131(5):512–521

Casanova P, Rossi P (1997) Analysis and design of steel fiber reinforced concrete beams. ACI Struct J 94:595–602

CNR-DT 204 (2006) Guidelines for design, construction and production control of fiber reinforced concrete structures. National Research Council of Italy, Italy

FIB (2010), “Model Code 2010” First complete draft. International Federation for Structural Concrete, Switzerland

Di Prisco M, Plizzari G, Vandevalle L (2009) Fibre reinforced concrete: new design perspectives. Mater Struct 42:1261–1281

De Montaignac R, Massicotte B, Charron J-P (2011) Design of SFRC structural elements: flexural behaviour prediction. Mater Struct. doi:10.1617/s11527-011-9785-y

Kitsutaka Y (1997) Fracture parameters by polylinear tension-softening analysis. J Eng Mech 123(5):444–450

Chanvillard G (2000) Characterization of fiber reinforced concrete mechanical properties: a review. In: Fiber-reinforced concrete BEFIB’ 2000, RILEM proceedings PRO15, pp 29–49

Sousa J, Gettu R (2006) Determining the tensile stress-crack opening curve of concrete by inverse analysis. J Eng Mech ASCE 132:141–148

Rossi P, Harouche N (1990) Mix design and mechanical behaviour of some steel-fibre reinforced concretes used in reinforced concrete structures. Mater Struct 23:256–266

Duong, V., “Comparison of flexure beam and plate load toughness testing”, undergraduate senior report, Department of civil engineering, University of New-Brunswick, December 2000

Bernard ES (2005) The role of friction in post-crack energy absorption of fiber reinforced concrete in the round panel test. J ASTM Int 2(1):1–12

Zhang J, Stang H (1998) Application of stress crack width relationship in predicting the flexural behavior of fiber-reinforced concrete. J Cem Concr Res 28(3):439–452

Nour A, Massicotte B, De Montaignac R, Charron JP (2011) Derivation of a crack opening deflection relationship for fibre reinforced concrete panels using a stochastic model: application for predicting the flexural behaviour of round panels using stress crack opening diagrams. J Cem Concr Res 41(9):964–974

Lambrechts A (2008) Performance classes for steel fibre reinforced concrete: be critical. In: BEFIB 2008 symposium, Chennai, India, 17–19 September 2008, pp 1007–1020

Lawler JS, Zampini D, Shaw SP (2002) Permeability of cracked hybrid fiber-reinforced mortar under load. ACI Mater J 99:379–385

Acknowledgments

This project has been financially supported by the Natural Sciences and Engineering Research Council (NSERC) of Canada, the Center for Research on Concrete Infrastructures of Quebec (FQRNT—CRIB). Materials were graciously provided by Bekaert, St-Laurence Cement, and Euclid.

Author information

Authors and Affiliations

Corresponding author

Appendix 1: predicting round panel deflection

Appendix 1: predicting round panel deflection

The relationships between the central deflection δ, the maximum crack width w t, the crack rotation θ and the crack depth z are given by the following equations for round panels with a symmetrical crack pattern, where Δ = δ/δ max (Figs. 5, 9) [23, 24]:

For unsymmetrical crack patterns, more general relationships are available in literature [24] to replace Eqs. 3 and 4. Cracking strength of concrete was assumed equal to:

Rights and permissions

About this article

Cite this article

de Montaignac, R., Massicotte, B., Charron, JP. et al. Design of SFRC structural elements: post-cracking tensile strength measurement. Mater Struct 45, 609–622 (2012). https://doi.org/10.1617/s11527-011-9784-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-011-9784-z