Abstract

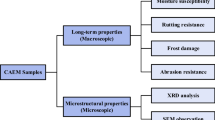

The interaction characteristics of cement asphalt composite mastic (CAM) and performance properties of cement asphalt emulsion mixtures (CAEM) were evaluated in this work using chemical and mechanical test methods to investigate the effect of the presence of cement on asphalt emulsion mixtures (AEM). The chemical composition of the CAM was obtained through use of X-ray diffraction, Fourier-transform infrared spectroscopy, and environmental scanning electron microscopy (ESEM) as a means to describe the interactions between the cement and asphalt in the composite materials. Test results demonstrated that cement can hydrate with the water phase of the asphalt emulsion. Asphalt droplets can simultaneously enclose cement particles and delay the hydration reaction process of cement. The interaction mechanism of cement particles or hydration products and residual asphalt is a physical compound process. The influence of these findings on asphalt emulsion mixture design and performance properties was assessed using varying mix design components and conducting laboratory-based mechanical test methods for rutting resistance and moisture susceptibility. Mix design components varied including added water content, emulsion content, and cement dosage levels. The optimum fluids content was determined based on the dry indirect tensile strength. It was found that the cement content significantly impacts the optimum fluids content for both added water and emulsion. Furthermore, the presence of cement improves the dry tensile strength, rutting resistance, and moisture susceptibility. Based on microstructural analysis of CAM and CAEM, the mechanism by which cement improves the performance of AEM is attributed to the ability of hydration products to increase both the stiffness of the asphalt binder and the adhesion at the mastic–aggregate interface. In practical applications, this study recommends a mix design method for cement-modified asphalt emulsion mixes (CAEM) based on selection of optimum cement and emulsion contents using indirect tensile strength and verification of the design through evaluation of the moisture susceptibility and rutting resistance of the CAEM mix. Threshold values of CAEM mix mechanical properties to determine the quality of the design are proposed.

Similar content being viewed by others

References

Asphalt Institute (1997) Asphalt cold mix manual. Manual Series No. 14, 3rd edn. Asphalt Institute, Lexington

Asphalt Institute (2008) Thickness design: asphalt pavements for highways & streets. Manual Series No. 1, 9th edn. Asphalt Institute, Lexington

Terrel RL, Wang CK (1971) Early curing behavior of cement modified asphalt emulsion mixtures. J Assoc Asphalt Paving Technol 40:108–125

Schmidt RJ, Santucci LE, Coyne LD (1973) Performance characteristics of cement-modified asphalt emulsion mixes. J Assoc Asphalt Paving Technol 42:300–319

Head RW (1974) An informal report of cold mix research using emulsified asphalt as a binder. J Assoc Asphalt Paving Technol 43:110–131

Gadallah AA, Wood LE, Yoder EJ (1979) Effect of Portland cement on certain characteristic of asphalt-emulsion-treated mixture. J Transportation Res Board 712:23–30

Uemura T, Nakamori Y (1993) Stabilization process of cement asphalt emulsion in Japan. First World Congress on Emulsions, Paris, 1993, pp 4-13-16/01-06

Poncino H, Andresi R, Martinez F (1993) A laboratory and field study of factors affecting the behaviour of emulsified asphalt mixes. First World Congress on Emulsions, Paris, pp 4-40-100/01-06

Sation A, Bourdrel D (1993) Cold double treatment process of road materials with Portland cement and asphalt emulsion. 5th Eurobitume Congress, Stockolm, pp 293–297

Li G, Zhao Y, Pang SS, Huang W (1998) Experimental study of cement-asphalt emulsion composite. Cement Concrete Res 28(5):635–641

Brown SF, Needham D (2000) A study of cement modified bitumen emulsion mixture. J Assoc Asphalt Paving Technol 69:92–121

Pouliot N, Marchand J, Pigeon M (2003) Hydration Mechanisms, microstructure, and mechanical properties of mortars prepared with mixed binder cement slurry-asphalt emulsion. J Mater Civ Eng 15(1):54–59

Oruc S, Fazil Celik M, Akpinar V (2007) Effect of cement on emulsified asphalt mixtures. J Mater Eng Perform 16(5):578–583

Garcia A, Lura P, Part MN (2012). Influence of cement content and environmental humidity on asphalt emulsion and cement composites performance. Mater Struct 1–15. November 15

Jada A, Florentin C, Mariotti S (2004) Study of the electrical properties of cationic bitumen emulsions by microelectrophoresis. Adv Colloid Interface Sci 108–109:127–132

Ministry of Transportation of the People’s Republic of China (2004) JTG F40 Technical specifications for construction of highway asphalt pavements. Beijing, China

Acknowledgments

The author would like to thank Dr. Andrew Hanz, University of Wisconsin-Madison, for providing an editorial review of this article. This research is supported by Fundamental Research Funds for the Central Universities (no. CHD 2011JC127).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Du, S. Interaction mechanism of cement and asphalt emulsion in asphalt emulsion mixtures. Mater Struct 47, 1149–1159 (2014). https://doi.org/10.1617/s11527-013-0118-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-013-0118-1