Abstract

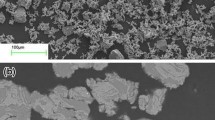

In this study, Porous NiTi shape memory alloy has been produced by mechanical alloying of the elemental Ni and Ti powders. The compacting process was done at two temperatures (warm and cold press) and then sintering at 980 and 1050°C was performed on the specimens. Microstructure and mechanical prop-erties of the samples were investigated by optical microscopy, scanning electron microscopy (SEM) and X-ray diffraction. Moreover, shear punch test (SPT) employed to investigate the effect of compaction pressure and sintering temperature on the mechanical properties of the fabricated samples. It was revealed that warm compaction/sintering resulted in 15% yield stress improvement and 20% ultimate tensile strength (UTS) enhancement with respect to conventionally produced specimens. The proposed approach in this paper seems a step forward towards fulfillment of the demand for heavy load-bearing artificial bone.

Similar content being viewed by others

References

Bram, M., Ahmad-Khanlou, A., Heckmann, A., Fuchs, B., Buchkremer, H.P., and Stover, D., Powder Metallurgical Fabrication Processes for NiTi Shape Memory Alloy Parts, Mater. Sci. Eng. A, 2002, vol. 337, pp. 254–263.

Otsuka, K. and Ren, X., Physical Metallurgy of Ti-Ni-Based Shape Memory Alloys, Prog. Mater Sci., 2005, vol. 50, pp. 511–678.

Prymak, O., Bogdanski, D., Koller, M., Esenwein, S.A., Muhr, G., Beckmann, F., Donath, T., Assad, M., and Epple, M., Morphological Characterization and in vitro Biocompatibility of a Porous Nickel-Titanium Alloy, Biomaterials, 2005, vol. 26, pp. 5801–5807.

Greiner, C., Oppenheimer, S.M., and Dunand, D.C., High Strength, Low Stiffness, Porous NiTi with Superelastic Properties, Acta Biomater., 2005, vol. 1, pp. 705–716.

Chu, C.L., Chung, C.Y., Lin, P.H., and Wang, S.D., Fabrication and Properties of Porous NiTi Shape Memory Alloys for Heavy Load-Bearing Medical Applications Journal of Materials Processing Technology, J. Mater. Process. Technol., 2005, vol. 169, pp. 103–107.

Li, Y.H., Rong, L.J., and Li, Y.Y., Pore Characteristics of Porous NiTi Alloy Fabricated by Combustion Synthesis, Journal of Alloys and Compounds, J. Alloys Compd., 2001, vol. 325, pp. 259–262.

Yuan, B., Chung, C.Y., and Zhu, M., Microstructure and Martensitic Transformation Behavior of Porous NiTi Shape Memory Alloy Prepared by Hot Isostatic Pressing Processing, Mater. Sci. Eng. A, 2004, vol. 181, p. 382.

Schüller, E., Bram, M., Buchkremer, H.P., and Stöver, D., Phase Transformation Temperatures for NiTi Alloys Prepared by Powder Metallurgical Processes, Mater. Sci. Eng. A, 2004, vol. 378, pp. 165–169.

Monastyrsky, G.E., Odnosum, V., Humbeeck, J.V., Kolomytsev, V.I., and Koval, Y.N., Powder Metallurgical Processing of Ni-Ti-Zr Alloys Undergoing Martensitic Transformation: Part I, Intermetallics, 2002, vol. 10, pp. 95–103.

Chu, C.L., Chung, C.Y., Lin, P.H., Wang, S.D., Fabrication of Porous NiTi Shape Memory Alloy for Hard Tissue Implants by Combustion Synthesis, Mater. Sci. Eng. A, 2004, vol. 366, pp. 114–119.

Sadrnezhaad, S.K. and Hosseini, S.A., Fabrication of Porous NiTi-shape Memory Alloy Objects by Partially Hydrided Titanium Powder for Biomedical Applications, Mater. Des., 2009, vol. 30, pp. 4483–4487.

Crone, W.C., Yahya, A.N., and Perepezko, J.H., Bulk Shape Memory NiTi with Refined Grain Size Synthesized by Mechanical Alloying, Mater. Sci. Forum, 2002, vol. 386, pp. 597–602.

Morris, D.G. and Morris, M.A., NiTi Intermetallic by Mixing, Milling and Interdiffusing Elemental Components, Materials Science and Engineering A, Mater. Sci. Eng. A, 1989, vol. 110, pp. 139–149.

Green, S.M., Grant, D.M., and Kelly, N.R., Powder Metallurgical Processing of Ni-Ti Shape-Memory Alloy, Powder Metallurgy, Powder Metall., 1997, vol. 10, pp. 43–47.

Green, S.M., Grant, D.M., and Wood, J.V., Shape Memory Transformation in Mechanically Alloyed Ni-5O at % Ti, J. Phys. IV france 7, 1997, vol. C5, p. 351.

Gharacheh, M.A., Kokabi, A.H., Daneshi, G.H., Shalchi, B., and Sarrafi, R., The Influence of the Ratio of “Rotational Speed/Traverse Speed” (ω/v) on Mechanical Properties of AZ31 Friction Stir Welds, Int. J. Mach. Tools Manuf., 2006, vol. 48, pp. 1983–1987.

Zhu, S.L., Yang, X.J., Hu, F., Deng, S.H., and Cui, Z.D., Processing of Porous TiNi Shape Memory Alloy from Elemental Powders by Ar-Sintering, Mater. Lett., 2004, vol. 58, pp. 2369–2373.

Bronzino, J.D., The Biomedical Engineering Handbook, 2nd ed., vol. 1, Boca Raton: CRC Press, 2000.

Hey, J.C. and Jardine, A.P., Shape Memory TiNi Synthesis from Elemental Powders, Mater. Sci. Eng. A, 1994, vol. 188, pp. 291–300.

Li, B.Y., Rong, L.J., Li, Y.Y., and Gjunter, V.E., A Recent Development in Producing Porous Ni-Ti Shape Memory Alloys, Intermetallics, 2000, vol. 8, pp. 881–884.

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

About this article

Cite this article

Parvizi, S., Hasannaeimi, V., Saebnoori, E. et al. Fabrication of porous NiTi alloy via powder metallurgy and its mechanical characterization by shear punch method. Russ. J. Non-ferrous Metals 53, 169–175 (2012). https://doi.org/10.3103/S1067821212020113

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821212020113