Abstract

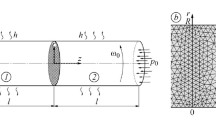

A calculation procedure to determine the temperature field during rotary friction welding of metal is proposed. An axisymmetric nonlinear boundary value problem of heat conduction taking into account the frictional heating of two cylinders (specimens) of finite length is formulated. It is assumed that the materials of specimens are thermally sensitive, and the friction coefficient depends on temperature. The solution of the problem is obtained by the finite element method. The numerical analysis was carried out for two identical specimens made of AISI 1040 grade steel.

Similar content being viewed by others

REFERENCES

Saeid, T., Abdollah-Zadeh, A., and Sazgari, B., Weldability and mechanical properties of dissimilar aluminum–copper lap joints made by friction stir welding, J. Alloys Compd., 2010, vol. 490, nos. 1–2, pp. 652–655.

Taban, E., Gould, J.E., and Lippold, J.C., Dissimilar friction welding of 6061-T6 aluminum and AISI 1018 steel: Properties and microstructural characterization, Mater. Des., 2010, vol. 31, no. 5, pp. 2305–2311.

Uday, M.B., Ahmad-Fauzi, M.N., Zuhailawati, H., and Ismail, A.B., Thermal analysis of friction welding process in relation to the welding of YSZ-alumina composite and 6061 aluminum alloy, Appl. Surf. Sci., 2012, vol. 258, no. 20, pp. 8264–8272.

Simões, F. and Rodrigues, D.M., Material flow and thermo-mechanical conditions during Friction Stir Welding of polymers: Literature review, experimental results and empirical analysis, Mater. Des., 2014, vol. 59, pp. 344–351.

Lebedev, V.K., Chernenko, I.A., Mikhal’ski, R., and Vill’, V.I., Svarka treniem (Welding by Friction), Leningrad: Mashinostroenie, 1987.

Maalekian, M., Friction welding—critical assessment of literature, Sci. Technol. Weld. Joining, 2007, vol. 12, no. 8, pp. 738–759.

Cheng, C.J., Transient temperature distribution during friction welding of two similar materials in tubular form, Weld. J., 1962, vol. 41, no. 12, pp. 542–550.

Sahin, A.Z., Yilbas, B.S., and Al-Garni, A.Z., Friction welding of Al-Al, Al-steel, and steel-steel samples, J. Mater. Eng. Perform., 1996, vol. 5, no. 1, pp. 89–99

Służalec, A., Thermal effects in friction welding, Int. J. Mech. Sci., 1990, vol. 32, no. 6, pp. 467–478.

Moal, A. and Massoni, E., Finite element simulation of the inertia welding of two similar parts, Eng. Comput., 1995, vol. 12, no. 6, pp. 497–512.

Fu, L. and Duan, L., The coupled deformation and heat flow analysis by finite element method during friction welding, Weld. J., 1998, vol. 77, no. 5, pp. 202–207.

Balasubramanian, V., Li, Y., Stotler, T., Crompton, J., Soboyejo, A., Katsube, N., and Soboyejo, W., A new friction law for the modeling of continuous drive friction welding: applications to 1045 steel welds, Mater. Manuf. Process., 1999, vol. 14, no. 6, pp. 845–860.

Li, W. and Wang, F., Modeling of continuous drive friction welding of mild steel, Mater. Sci. Eng., A, 2011, vol. 528, no. 18, pp. 5921–5926.

Maalekian, M., Kozeschink, E., Brantner, H.P., and Cerjak, H., Comparative analysis of heat generation in friction welding of steel bars, Acta Mater., 2008, vol. 56, no. 12, pp. 2843–2855.

Zimmerman, J., Wlosinski, W., and Lindemann, Z.R., Thermo-mechanical and diffusion modeling in the process of ceramic–metal friction welding, J. Mater. Process. Technol., 2009, vol. 209, no. 4, pp. 1644–1653.

Bouarroudj, E., Chikh, S., Abdi, S., and Miroud, D., Thermal analysis during a rotational friction welding, Appl. Therm. Eng., 2017, vol. 110, pp. 1543–1553.

Ling, F.F., Surface Mechanics, New York: Wiley. 1973.

COMSOL Multiphysics v. 5.2a, Stockholm, 2016. http://www.comsol.com.

High-Temperature Property Data: Ferrous Alloys, Rothman, M.F., Ed., Materials Park, OH: ASM Int., 1988.

ACKNOWLEDGMENTS

This work is a part of scientific-research project no. S/WM/1/2018, which was realised at Bialystok University of Technology.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by M. Kromin

About this article

Cite this article

Łukaszewicz, A. Nonlinear Numerical Model of Friction Heating during Rotary Friction Welding. J. Frict. Wear 39, 476–482 (2018). https://doi.org/10.3103/S1068366618060089

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068366618060089