Abstract

The present study investigated the effects of initial Hydrogen level and cooling rate on ultimate tensile strength of commercial Al-A319 alloys. Three hydrogen levels (0.01, 0.2, and 0.41 mL/100 grams of melt) and five cooling rate were studied. Total of 45 tensile test bars was prepared (three hydrogen levels × five cooling rate × three repeats). The UTS of the samples was determined though uniaxial tension tests. Furthermore, the microstructures of the samples were studied by standard metallographic technique and image analysis software. Finally the relationship between UTS and microstructurai features—SDAS and fraction of porosity (Fp%)—of the alloys was investigated.

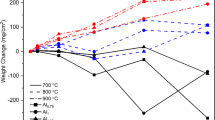

Results of tensile test revealed: (i) UTS of the alloy decreased with increasing of hydrogen level or decreasing of cooling rate and (ii) Increasing of cooling rate beyond a certain value increased the UTS of the alloy significantly. Results of image analysis showed that the Fp% increased with increasing of hydrogen level and decreasing of cooling rate.

Finally a Matrix Index [= −SDAS (μm) − 68.7 Ln (Fp%) + 275] was defined to correlate the tensile strength and microstructurai features of the alloy. It was shown that the UTS of the alloys had a linear dependence on matrix index according the below equation:

Similar content being viewed by others

References

Sebaie, O.E., Samuel, A., Samuel, F., and Doty, H., Mater. Sci. Eng., 2008, vol. A 480, pp. 342–355.

García-Garcia, G., Espinoza-Cuadra, J., and Mancha-Molinar, H., Mater. Des., 2007, vol. 28, pp. 428–433.

Firouzdor, V., Rajabi, M., Nejati, E., and Khomamizadeh, F., Mater. Sci. Eng., 2007, vol. A 454, pp. 528–535.

Rincon, E., Lopez, H., Cisneros, M., and Mancha, H., Mater. Sci. Eng., 2009, vol. A 519, pp. 128–140.

Eisaabadi, G.B., Davami, P., Kim, S., and Varahram, N., Mater. Sci. Eng., 2012, vol. A 552, pp. 36–47.

Eisaabadi, G.B., Varahram, N., Davami, P., and Kim, S.K., Mater. Sci. Eng., 2012, vol. A 548, pp. 99–105.

Kashyap, K., Murali, S., Raman, K., and Murthy, K., Mater. Sci. Technol., 1993, vol. 9, pp. 189–204.

Sigworth, G., Shivkumar, S., and Apelian, D., Trans. AFS, 1989, vol. 97, pp. 811–824.

Samuel, A. and Samuel, F., Metall. Mater. Trans., 1995, vol. A 26, pp. 2359–2372.

Martinez, E.D., Cisneros, M.G., Valtierra, S., and Lacaze, J., Scr. Mater., 2005, vol. 52, pp. 439–443.

Anson, J. and Gruzleski, J., Mater. Charact., 1999, vol. 43, pp. 319–335.

Ma, Z., Samuel, A., Samuel, F., Doty, H., and Valtierra, S., Mater. Sci. Eng., 2008, vol. A 490, pp. 36–51.

Tekmen, C., Ozdemir, I., Cocen, U., and Onel, K., Mater. Sci. Eng., 2003, vol. A 360, pp. 365–371.

Irfan, M., Schwam, D., Karve, A., and Ryder, R., Mater. Sci. Eng., 2011, vol. A 535, pp. 108–114.

Dispinar, D., Akhtar, S., Nordmark, A., and Syvertsen, F., Adv. Mater. Res., 2012, vol. 445, pp. 283–288.

Caceres, C., Djurdjevic, M., Stockwell, T., and Sokolowski, J., Scr. Mater., 1999, vol. 42.

Li, Z., Samuel, A., Samuel, F., Ravindran, C., and Valtierra, S., Mater. Sci. Eng., 2004, vol. A 367, pp. 96–110.

Heiberg, G., Raanes, M., Arnberg, L., Nogita, K., Dahle, A., and Dons, A., Trans. AFS, 2002, vol. 110, pp. 347–358.

Bahmani, A., Hatami, N., Varahram, N., Davami, P., and Shabani, M.O., Int. J. Adv. Manuf. Technol., 2012, vol. 64, pp. 1313–1321.

Pennors, A., Samuel, A., Samuel, F., and Doty, H., Trans. AFS, 1998, vol. 106, pp. 251–264.

Samuel, A., Pennors, A., Villeneuve, C., Samuel, F., and Doty, H., Int. J. Cast Met. Res., 2000, vol. 13, p. 231.

Cao, X. and Campbell, J., Mater. Trans., JIM, 2006, vol. 47, pp. 1303–1312.

Shabani, M.O., Mazahery, A., Bahmani, A., Davami, P., and Varahram, N., Kovove Mater., 2011, vol. 49, pp. 253–264.

Hafiz, M.F. and Kobayashi, T., Scr. Metall. Mater., 1994, vol. 30.

Saigal, A. and Fuller, E.R., Computational Materials Science, 2001, vol. 21, pp. 149–158.

Samuel, F., Samuel, A., and Doty, H., Trans. AFS, 1996, vol. 104, pp. 893–902.

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

About this article

Cite this article

Bahmani, A., Eisaabadi, G.B., Davami, P. et al. Effects of hydrogen level and cooling rate on ultimate tensile strength of Al A319 alloy. Russ. J. Non-ferrous Metals 55, 365–370 (2014). https://doi.org/10.3103/S106782121404004X

Published:

Issue Date:

DOI: https://doi.org/10.3103/S106782121404004X