Abstract

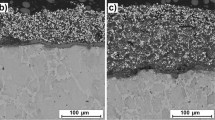

The effect of sulfacyanization of ZrN and Mo+Mo2N coatings on the volume wear of hard-alloy blade cutting knives when milling chipboard laminated wood was investigated. It is revealed that this treatment reduces the volume wear of knife blades two times. Nitride coatings promote the hardness and deformation resistance of blades. Sulfacyanization forms surface film containing C, S, and N. This film is deeply deformed through the edges and pores of carbide grains reducing friction and oxidation of blades in cutting.

Similar content being viewed by others

References

LEKSIKON Leitts: katalog firmy Leitz (LEKSIKON Leitz: Leitz Co. Catalog), Moscow: OOO “Leitts Instrumenty”, 2011.

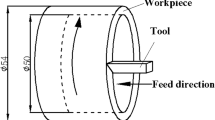

Rapovets, V.V., Practical results of experimental study of wood cutting by double-edge cutters in chippering canters, Trudy BGTU. Ser. II, Lesnaya i Derevoobrab. Prom., Minsk, 2008, no. XVI, pp. 205–208.

Anikeenko, A.F. and Fridrikh, A.P., Recommendations on methods of studies in machining of laminated wood-chip board, Trudy BGTU. Lesnaya i Derevoobrab. Prom., Minsk, 2011, vol. 140, no. 2, pp. 313–315.

Anikeenko, A.F. and Grishkevich, A.A., Method for experimental study of milling of wooden board materials in Rover b4.35 NC machining center, Trudy BGTU. Ser. II, Lesnaya i Derevoobrab. Prom., Minsk, 2007, no. XV, pp. 213–216.

Abrazumov, V.V., Wear resistance of cutting tools during machining of wooden composite materials, Doctoral (Eng.) Dissertation, Moscow, 2009.

Aronson, R., Up-to-date materials in machine building: specific features and field of application, Manuf. Eng., 2002, vol. 127, no. 3, pp. 123–136.

Moiseev, A.V., Contact phenomena in edge microzone during wood cutting and their effect on origin of tool dulling: Extended Abstract of Doctoral (Eng.) Dissertation, Moscow, 1983.

Vereshchaka, A.C. and Tret’yakov, I.P., Rezhushchie instrumenty s iznosostoikimi pokrytiyami (Cutting Tools with Wear-Resistant Coatings), Moscow: Mashinostroenie, 1986.

Vereshchaka, A.S., Rabotosposobnost’ rezhushchego instrumenta s iznosostoikimi pokrytiyami (Serviceability of Cutting Tools with Wear-Resistant Coatings), Moscow: Mashinostroenie, 1993.

Belyi, A.V., Karpenko, G.D., and Myshkin, N.K., Struktura i metody formirovaniya iznosostoikikh poverkhnostnykh sloev (Structure and Methods for Producing Wear-Resistant Surface Layers), Moscow: Mashinostroenie, 1991.

Kuleshov, A.K., Uglov, V.V., Chayevski, V.V., and Anishchik, V.M., Properties of coatings based on Cr, Ti, Mo nitrides with embedded metals deposited on cutting tools, J. Frict. Wear, 2011, vol. 32, no. 3, pp. 192–198.

Grishkevich, A.A., et al., Efficiency of use of TiN-, ZrN-, Ti-Zr-N-, and Ti-coatings on hard alloy during machining of laminated woodchip board using end cutters, Trudy BGTU. Ser. VI, Fiz.-Mat. Nauki i Informatika, 2008, no. XVI, pp. 52–54.

Grishkevich, A.A., et al., Peculiarities of wear of knife edges of wood-milling cutters hardened by ion-bombardment assisted condensation during machining of laminated woodchip board, Sb. mater. VII Mezhdunar. nauch.-tekhn. konf. “Sovremennye metody i tekhnologii sozdaniya i obrabotki materialov” (Proc. 7th Int. Sci. and Tech. Conf. “Advanced Methods and Technologies for Production and Machining of Materials”), Minsk: FTI NAN Belarusi, 2012, vol. 2, pp. 297–303.

Uglov, V.V., et al., Thermochemical treatment of hardalloy wood-working tools, Sb. mater. VII Mezhdunar. nauch.-tekhn. konf. “Sovremennye metody i tekhnologii sozdaniya i obrabotki materialov” (Proc. 7th Int. Sci. and Tech. Conf. “Advanced Methods and Technologies for Production and Machining of Materials”), Minsk: FTI NAN Belarusi, 2012, vol. 2, pp. 152–157.

Grishkevich, A.A. and Chayevski, V.V., Effect of ionplasma coatings on wear resistance of steel cutters during wood cutting in chippering canters, Trudy BGTU. Ser. II, Lesnaya i Derevoobrab. Prom., 2010, no. XVIII, pp. 348–351.

Kuleshov, A.K., et al., Thermal stability of surface layers of titanium and chromium nitrides deposited on T16K6 hard alloy by ion-bombardment assisted condensation, Perspektivnye Mater., 2009, no. 2, pp. 68–73.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.K. Kuleshov, V.V. Uglov, D.P. Rusalsky, A.A. Grishkevich, V.V. Chayeuski, V.N. Haranin, 2014, published in Trenie i Iznos, 2014, Vol. 35, No. 3, pp. 276–286.

About this article

Cite this article

Kuleshov, A.K., Uglov, V.V., Rusalsky, D.P. et al. Effect of ZrN and Mo-N coatings and sulfacyanization on wear of wood-cutting knives. J. Frict. Wear 35, 201–209 (2014). https://doi.org/10.3103/S1068366614030076

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068366614030076