Structural Behavior of a Composite Curtain Wall Fabricated by the Fused Deposition Modeling 3D Printing Method

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fused Deposition Modeling 3D Printing Method

2.2. ABS-M30 Polymer

2.3. Cellulose-Fiber-Reinforced Cement Board

2.4. Harmony Search Algorithm

3. 3D Printed Composite Curtain Wall (3DP CCW) System

3.1. Introduction

3.2. Shape Optimization of the 3DP CCW

3.2.1. Unit Size Optimization of O-Type ABS Polymer Board

3.2.2. Unit Size Optimization of W-Type ABS Polymer Board

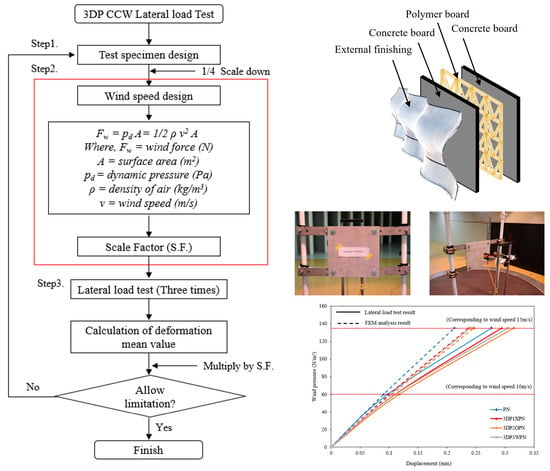

4. Lateral Load Test and FEM Analysis for 3DP CCW

4.1. Laster Load Test

4.1.1. Test Plan

4.1.2. Wind Speed Design

4.1.3. Test Setup

4.2. FEM Analysis

5. Results and Discussion

5.1. Laster Load Test and FEM Analysis Results

5.1.1. Lateral Load Test Results

5.1.2. FEM Analysis Results

5.2. Discussion

6. Conclusions

- (1)

- The lateral load test and FEM analysis were performed to measure the structural and residual deformations under wind speeds of 100% and 150% of the design wind speed; subsequently, the original model deformation under the average wind speed in the area of Seoul was calculated through the S.F. The FEM analysis and lateral load test results were compared, which were based on the premise that PN is used as the standard specimen. In terms of central deformation, the minimum deformation was obtained by the two methods for 3DP1XPN, and the difference between the data obtained by the two methods was 10% at 100% of the design wind speed. As the wind speed increased to 150% of the design wind speed, the data difference between the two methods increased to 23%. However, when considering the cost and deformation simultaneously, since the deformation of all the specimens and the residual deformation satisfied the requirements of the standard, the specimen with the smallest weight, i.e., 3DP2OPN, was selected as the optimal model.

- (2)

- In the lateral load test, the cement board material cannot be guaranteed to be homogeneous. In addition, the pin connection will cause problems, such as rotation with the increase in wind speed, resulting in stress concentration at the connection. The strength of the bolts cannot be guaranteed to be consistent during the test, which could cause an uneven force on the cladding, thus making the result unreliable. Therefore, further studies are required to avoid these errors.

- (3)

- Future research should be conducted with high-capacity test equipment to apply 26 m/s wind speed. In addition, the various connection details and full-scale tests should be conducted to investigate the actual behavior of the full-scale 3DP CCW and install it at the buildings.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Wu, P.; Wang, J.; Wang, X. A critical review of the use of 3-D printing in the construction industry. Automat. Constr. 2016, 68, 21–31. [Google Scholar] [CrossRef] [Green Version]

- Mazzati, V.; Malagutti, L.; Mollica, F. FDM 3D printing of polymers containing natural fillers: A review of their mechanical properties. Polymers 2019, 11, 1094. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gosselin, C.; Duballet, R.; Roux, P.; Gaudillière, N.; Dirrenberger, J.; Morel, P. Large-scale 3D printing of ultra-high-performance concrete–a new processing route for architects and builders. Mater. Design 2016, 100, 102–109. [Google Scholar] [CrossRef] [Green Version]

- Tay, Y.W.D.; Panda, B.; Paul, S.C.; Noor Mohamed, N.A.; Tan, M.J.; Leong, K.F. 3D printing trends in building and construction industry: A review. Virtual. Phys. Prototy. 2017, 12, 261–276. [Google Scholar] [CrossRef]

- Moghtadernejad, S.; Mirza, M.S.; Chouinard, L.E. Facade design stages: Issues and considerations. J. Archit. Eng. 2019, 25, 04018033. [Google Scholar] [CrossRef]

- Takano, A.; Hughes, M.; Winter, S. A multidisciplinary approach to sustainable building material selection: A case study in a Finnish context. Build. Environ. 2014, 82, 526–535. [Google Scholar] [CrossRef]

- Bedon, C.; Zhang, X.; Santos, F.; Honfi, D.; Kozłowski, M.; Arrigoni, M.; Lange, D. Performance of structural glass facades under extreme loads–Design methods, existing research, current issues and trends. Constr. Build. Mater. 2018, 163, 921–937. [Google Scholar] [CrossRef]

- Zelenay, K.; Perepelitza, M.; Lehrer, D. High-Performance Facades Design Strategies and Applications in North America and Northern Europe; UC Berkeley, Center for the Built Environment: Berkeley, CA, USA, 2011; Available online: https://escholarship.org/uc/item/4vq936rc (accessed on 14 March 2022).

- Nguyen, Q.T.; Ngo, T.; Mendis, P.; Tran, P. Composite materials for next generation building facade systems. Civil. Eng. Archit. 2013, 1, 88–95. [Google Scholar] [CrossRef]

- Manalo, A.; Aravinthan, T.; Fam, A.; Benmokrane, B. State-of-the-art review on FRP sandwich systems for lightweight civil infrastructure. J. Compos. Constr. 2017, 21, 04016068. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.B. Major Parameter Effect Analysis for Deriving the Optimal Shape of 3D Printing Cementitious Cladding. Master’s Thesis, Korea University, Seoul, Korea, 2017. (In Korean). [Google Scholar]

- Bae, J.H.; Zhang, Z.Y.; Ju, Y.K. The Shape Optimization of PLA Polymer Space Truss Using 3D Printer. J. Korean Assoc. Spat. Struct. 2020, 20, 61–67. [Google Scholar] [CrossRef]

- Croccolo, D.; De Agostinis, M.; Olmi, G. Experimental characterization and analytical modelling of the mechanical behaviour of fused deposition processed parts made of ABS-M30. Comp. Mater. Sci. 2013, 79, 506–518. [Google Scholar] [CrossRef]

- Shubham, P.; Sikidar, A.; Chand, T. The influence of layer thickness on mechanical properties of the 3D printed ABS polymer by fused deposition modeling. Key Eng. Mater. 2016, 706, 63–67. [Google Scholar] [CrossRef]

- Tanoto, Y.Y.; Anggono, J.; Budiman, W.; Philbert, K.V. Strength and Dimension Accuracy in Fused Deposition Modeling: A Comparative Study on Parts Making Using ABS and PLA Polymers. Rekayasa. Mesin. 2020, 11, 69–76. [Google Scholar] [CrossRef]

- Zein, I.; Hutmacher, D.W.; Tan, K.C.; Teoh, S.H. Fused deposition modeling of novel scaffold architectures for tissue engineering applications. Biomaterials 2002, 23, 1169–1185. [Google Scholar] [CrossRef]

- Dudek, P. FDM 3D printing technology in manufacturing composite elements. Arch. Metall. Mater. 2013, 58, 1415–1418. [Google Scholar] [CrossRef]

- Perez, M.; Block, M.; Espalin, D.; Winker, R.; Hoppe, T.; Medina, F.; Wicker, R. Sterilization of FDM-manufactured parts. In Proceedings of the 23rd Annual International Solid Freefrom Fabrication Symposium: An Additive Manufacturing Conference, Austin, TX, USA, 6–8 August 2012. [Google Scholar]

- Novakova-Marcincinova, L.; Novak-Marcincin, J. Testing of the ABS materials for application in fused deposition modeling technology. Appl. Mech. Mater. 2013, 309, 133–140. [Google Scholar] [CrossRef]

- Lukmanova, L.V.; Mukhametrakhimov, R.K.; Gilmanshin, I.R. Investigation of mechanical properties of fiber-cement board reinforced with cellulosic fibers. In Proceedings of the International Scientific-Technical Conference on Innovative Engineering Technologies, Equipment and Materials 2018, Kazan, Russia, 5–7 December 2018. [Google Scholar]

- Geem, Z.W.; Kim, J.H.; Loganathan, G.V. A new heuristic optimization algorithm: Harmony search. Simulation 2001, 76, 60–68. [Google Scholar] [CrossRef]

- Chakraborty, P.; Roy, G.G.; Das, S.; Jain, D.; Abraham, A. An improved harmony search algorithm with differential mutation operator. Fund. Inform. 2009, 95, 401–426. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.-B.; Park, M.-J.; Ju, Y.K. Structural behavior analysis of polymer lattice reinforced 3D printing cementitious cladding. J. Arch. Inst. Korea 2018, 34, 3–10. (In Korean) [Google Scholar]

- Gilbert, M.; He, L.; Pritchard, T. The yield-line method for concrete slabs: Automated at last. Struct. Eng. 2015, 93, 44–48. [Google Scholar]

- American Concrete Institute. ACI Committee 318; Building Code Requirements for Structural Concrete: (ACI 318-14) and Commentary; American Concrete Institute: Farmington Hills, MI, USA, 2014. [Google Scholar]

- Al-Ansari, M.S. Teaching two-way ribbed slab analysis and design using the MathCAD program. World Trans. Eng. Technol. Educ. 2006, 5, 457. [Google Scholar]

- MOLIT. Korean Construction Standard; Ministry of Land, Infrastructure and Transport: Sejong City, Korea, 2018. Available online: https://www.molit.go.kr/english/intro.do (accessed on 14 March 2022). (In Korean)

- MOLIT. Korean Design Standard; Ministry of Land, Infrastructure and Transport: Sejong City, Korea, 2019. Available online: https://www.molit.go.kr/english/intro.do (accessed on 14 March 2022). (In Korean)

- Rebelo, H.B.; Lecompte, D.; Cismasiu, C.; Jonet, A.; Belkassem, B.; Maazoun, A. Experimental and numerical investigation on 3D printed PLA sacrificial honeycomb cladding. Int. J. Impact Eng. 2019, 131, 162–173. [Google Scholar] [CrossRef]

| Density (kg/m3) | Tensile Strength (MPa) | Tensile Elongation (%) | Modulus of Elasticity (MPa) | Flexural Strength (MPa) | Poisson’s Ratio | Polymer Type |

|---|---|---|---|---|---|---|

| 1010 | 31.0 | 7.00 | 2230 | 60.0 | 0.2 | Amorphous |

| Data Group | Length (mm) | Width (mm) | Volume (cm3) | Displacement (mm) |

|---|---|---|---|---|

| 1 | 21 | 32 | 204.7 | 0.1041 |

| 2 | 23 | 39 | 192.5 | 0.1355 |

| 3 | 23 | 48 | 185.8 | 0.1631 |

| 4 | 33 | 39 | 175.6 | 0.1853 |

| 5 | 33 | 50 | 166.8 | 0.2329 |

| 6 | 56 | 39 | 156.2 | 0.2979 |

| 7 | 51 | 49 | 150.3 | 0.3374 |

| 8 | 58 | 49 | 146.0 | 0.3805 |

| 9 | 76 | 48 | 139.2 | 0.4786 |

| 10 | 50 | 82 | 135.6 | 0.5370 |

| 11 | 76 | 66 | 128.0 | 0.6464 |

| 12 | 67 | 92 | 122.8 | 0.7840 |

| 13 | 94 | 82 | 116.3 | 0.9758 |

| 14 | 94 | 98 | 112.1 | 1.150 |

| Data Group | Length (mm) | Width (mm) | Volume (cm3) | Displacement (mm) |

|---|---|---|---|---|

| 1 | 12 | 18 | 266.6 | 0.03409 |

| 2 | 12 | 24 | 254.7 | 0.04294 |

| 3 | 12 | 48 | 231.2 | 0.07562 |

| 4 | 44 | 16 | 216.2 | 0.08666 |

| 5 | 33 | 24 | 200.7 | 0.09554 |

| 6 | 24 | 47 | 184.1 | 0.1314 |

| 7 | 43 | 41 | 156.6 | 0.1936 |

| 8 | 45 | 48 | 147.0 | 0.2294 |

| 9 | 44 | 63 | 136.0 | 0.2876 |

| 10 | 72 | 46 | 129.0 | 0.3337 |

| 11 | 100 | 47 | 116.6 | 0.4626 |

| 12 | 99 | 63 | 102.1 | 0.5940 |

| 13 | 72 | 116 | 91.16 | 0.7806 |

| 14 | 144 | 76 | 82.77 | 1.012 |

| 15 | 134 | 95 | 76.10 | 1.155 |

| Specimen | Composition | Weight (kg) | Weight Residual of PN |

|---|---|---|---|

| PN | CRC panel | 1.847 | 100% |

| 3DP1XPN | CRC panel + X-type board | 1.485 | 80.4% |

| 3DP2OPN | CRC panel + O-type board | 1.388 | 75.2% |

| 3DP3WPN | CRC panel + W-type board | 1.432 | 77.5% |

| Time (s) | Wind Speed (m/s) | Wind Pressure (Pa) | Allowable Value |

|---|---|---|---|

| 10 | 5 (50%) | 15 | |

| 10 | 10 (100%) | 60 | L/360 |

| Time (s) | Wind Speed (m/s) | Wind Pressure (Pa) | Allowable Value |

|---|---|---|---|

| 10 | 5 (50%) | 15 | |

| 10 | 10 (100%) | 60 | L/360 |

| 10 | 15 (150%) | 135 | 2L/1000 |

| Specimen | Max. Disp. in L1 (mm) | Multiple by S.F. (mm) | Max. Disp. in L2 (mm) | Multiple by S.F. (mm) |

|---|---|---|---|---|

| PN | 0.098 | 0.784 | 0.277 | 2.22 |

| 3DP1XPN | 0.111 | 0.888 | 0.294 | 2.35 |

| 3DP20PN | 0.118 | 0.944 | 0.315 | 2.52 |

| 3DP3WPN | 0.113 | 0.904 | 0.305 | 2.44 |

| Model Name | 3DP CCW Maximum Deformation | ABS Polymer Maximum Deformation |

|---|---|---|

| PN |  |  |

| 3DP1XPN |  |  |

| 3DP20PN |  |  |

| 3DP3WPN |  |  |

| Specimen | Max. Disp. in L1 (mm) | Multiple by S.F. (mm) | Max. Disp. in L2 (mm) | Multiple by S.F. (mm) |

|---|---|---|---|---|

| PN | 0.091 | 0.728 | 0.223 | 1.78 |

| 3DP1XPN | 0.101 | 0.808 | 0.238 | 1.90 |

| 3DP20PN | 0.105 | 0.84 | 0.248 | 1.98 |

| 3DP3WPN | 0.103 | 0.824 | 0.242 | 1.94 |

| Specimen | PN | 3DP1XPN | 3DP2OPN | 3DP3WPN |

|---|---|---|---|---|

| FEM analysis results in L1 (mm) | 0.091 | 0.101 | 0.105 | 0.104 |

| Test results in L1 (mm) | 0.098 | 0.111 | 0.118 | 0.113 |

| Differences | 7.7% | 9.9% | 12.4% | 8.7% |

| FEM analysis results in L2 (mm) | 0.223 | 0.238 | 0.248 | 0.242 |

| Test results in L2 (mm) | 0.277 | 0.294 | 0.315 | 0.305 |

| Differences | 24.2% | 23.5% | 27.0% | 26.0% |

| Reference | Method | Material | Internal Reinforcement | Minimum Deformation |

|---|---|---|---|---|

| [12]: Numerical investigation | 3D concrete printing | PLA | Wire mesh (rectangular and diagonal) | R: 1.10 mm D: 1.11 mm |

| [13]: Numerical investigation | 3D printing robot | PLA | Space truss | 1.92 mm |

| [30]: Experimental and numerical investigation | FDM | PLA | Honeycomb structure | 39.1 mm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, M.J.; Bae, J.; Ju, Y.K. Structural Behavior of a Composite Curtain Wall Fabricated by the Fused Deposition Modeling 3D Printing Method. Polymers 2022, 14, 1431. https://doi.org/10.3390/polym14071431

Park MJ, Bae J, Ju YK. Structural Behavior of a Composite Curtain Wall Fabricated by the Fused Deposition Modeling 3D Printing Method. Polymers. 2022; 14(7):1431. https://doi.org/10.3390/polym14071431

Chicago/Turabian StylePark, Min Jae, Jaehoon Bae, and Young K. Ju. 2022. "Structural Behavior of a Composite Curtain Wall Fabricated by the Fused Deposition Modeling 3D Printing Method" Polymers 14, no. 7: 1431. https://doi.org/10.3390/polym14071431