tribAIn—Towards an Explicit Specification of Shared Tribological Understanding

Abstract

:1. Introduction

2. Methods

2.1. Philosophy of TribAIn

2.2. Purpose and Scope of TribAIn

- Influencing factors on the behavior of a specific tribological system: Many experiments in tribology aim to investigate the influence of a specific parameter or testing condition on the behavior of a specific tribological system. Containing all relevant constraints, like material pairing, ambient medium, as well as the properties of the bodies being in contact, the tribological system functions as a controllable reference model for real-world entities. Example CQs: What is the influence of a parameter on experimental results (e.g., frictional/wear behavior) within a certain tribological system? What is the influence of a coating/lubricant on experimental results within a tribological system?

- Experimental coverage: Avoiding re-testing, the ontology model should be able to answer queries about which kind of experiments are already conducted and documented in the knowledge base. Example CQs: Which variables were tested regarding their influence on the behavior of a material pairing (e.g., a steel/steel-contact)? Which tribological systems were investigated under dry-running conditions using a solid lubricant?

- Querying, analyzing, and comparing sensor data: Tribological experiments produce lots of sensor data in the form of measurement series. These are assessed and compared to interpret the behavior of a tribological system. One major challenge in comparing this data is the different terminology used within the domain. Example CQs: Which values has the coefficient of friction (COF) of sample XY? How does the value series of the COF for sample XY differ from the series of sample AB?

- Annotating experimental results: The practice of presenting results from tribological experiments in the natural language leads to the need for formal annotations; thus, the context and interpretation of measured sensor data can be provided. Example CQs: What was the research hypothesis behind an experimental result? What was the interpretation of a higher wear volume of one sample compared with another?

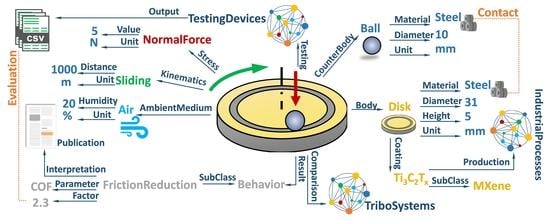

2.3. Use Case: MXene Nanosheets as Solid Lubricants

2.4. Concepts and Terminology in the Domain of Tribology

3. Results

3.1. Use Case: Competency Questions with Regard to MXene Nanosheets as Solid Lubricants

- What is the influence of the ambient relative humidity on the friction behavior in dry steel/steel sliding contacts?

- Are MXenes able to reduce friction and/or when used as a solid lubricant in dry steel/steel sliding contacts?

- What is the influence of pressure on the friction and wear performance of MXene-coated steel/steel contacts under dry sliding?

- What is the influence of the ambient relative humidity on the friction and wear performance of MXene-coated steel/steel contacts under dry sliding?

3.2. Linking Experimental Design and Results

- The testing device provides output tabular data in CSV (comma-separated values) format;

- Technical description, CAD models, and technical drawings;

- The results as well as their interpretation are described in the natural language; and

- The experimental design and parameters of the experimental setup are roughly implicit and can partly be accessed by interpreting the information from the CSV files’ header and the description in the publication.

3.3. Querying TribAIn

- SELECT ?FrictionalBehavior ?Result ?Humidity ?refHumidity

- WHERE {?X a tAI:FrictionalBehavior;

- tAI:textualInterpretation ?Result;

- tAI:hasTargetVariable ?Y.

- ?FrictionalBehavior rdf:SubClassOF tAI:FrictionalBehavior.

- ?Y a tAI:Humidity;

- tAI:hasValue ?Humidity;

- tAI:comparedWith ?Z.

- ?Z a tAI:Humidity;

- tAI:hasValue ?refHumidity.

- ?A tAI:hasKinematicalParameter tAI:Sliding;

- tAI:hasContact tAI:SteelSteel.

- MINUS {?A tAI:InterfacialMedium ?B.}}

- ASK {?X a tAI:TribologicalReferenceMethod;

- tAI:resultsIn tAI:FrictionReduction;

- tAI:hasBody ?Y.

- ?Y tAI:coatedWith ?Z.

- ?Z a tAI:MXene;

- a tAI:SolidLubricant.}

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jost, H.P. Lubrication: Tribology; Education and Research; Report on the Present Position and Industry’s Needs; HM Stationery Office: Richmond, UK, 1966. [Google Scholar]

- Holmberg, K.; Erdemir, A. Influence of tribology on global energy consumption, costs and emissions. Friction 2017, 3, 263–284. [Google Scholar] [CrossRef]

- Lee, P.M.; Carpick, R. Tribological opportunities for enhancing America’s energy efficiency. In A report to the Advanced Research Projects Agency-Energy (ARPA-E) at the US Department of Energy; Advanced Research Projects agency – Energy: Washington, DC, USA, 2017. [Google Scholar]

- Holmberg, K.; Kivikytö-Reponen, P.; Härkisaari, P.; Valtonen, K.; Erdemir, A. Global energy consumption due to friction and wear in the mining industry. Tribol. Int. 2017, 115, 116–139. [Google Scholar] [CrossRef]

- Nosonovsky, M.; Bhushan, B. Green Tribology: Biomimetics, Energy Conservation and Sustainability; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Holmberg, K.; Andersson, P.; Erdemir, A. Global energy consumption due to friction in passenger cars. Tribol. Int. 2012, 47, 221–234. [Google Scholar] [CrossRef]

- Holmberg, K.; Siilasto, R.; Laitinen, T.; Andersson, P.; Jäsberg, A. Global energy consumption due to friction in paper machines. Tribol. Int. 2013, 62, 58–77. [Google Scholar] [CrossRef]

- Holmberg, K.; Andersson, P.; Nylund, N.-O.; Mäkelä, K.; Erdemir, A. Global energy consumption due to friction in trucks and buses. Tribol. Int. 2014, 94–114. [Google Scholar] [CrossRef]

- Fries, J.R.; Kennedy, F.E. Bibliographic Databases in Tribology. J. Tribol. 1985, 3, 285–294. [Google Scholar] [CrossRef]

- Roucoules, L.; Yahia, E.; Es Soufi, W.; Tichkiewitch, S. Engineering design memory for design rationale and change management toward innovation. CIRP Ann. 2016, 1, 193–196. [Google Scholar] [CrossRef] [Green Version]

- Vakis, A.I.; Yastrebov, V.A.; Scheibert, J.; Nicola, L.; Dini, D.; Minfray, C.; Almqvist, A.; Paggi, M.; Lee, S.; Limbert, G.; et al. Modeling and simulation in tribology across scales: An overview. Tribol. Int. 2018, 125, 169–199. [Google Scholar] [CrossRef]

- Ji, Y.; Bao, J.; Yin, Y.; Ma, C. Applications of Artificial Intelligence in Tribology. Recent Pat. Mech. Eng. 2016, 3, 193–205. [Google Scholar] [CrossRef]

- Czichos, H.; Habig, K.-H. Tribologie-Handbuch; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2015. [Google Scholar] [CrossRef]

- Cheutet, V.; Leclaire, P.; Botelho, T.D.S.; Inglebert, G. Capitalizing Data, Information and Knowledge on Mechanical Experiments through Ontologies. In IFIP International Conference on Product Lifecycle Management; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Martinez-Cruz, C.; Blanco, I.J.; Vila, M.A. Ontologies versus relational databases: Are they so different? A comparison. Artif. Intell. Rev. 2012, 4, 271–290. [Google Scholar] [CrossRef]

- Xie, H.C.; Wang, J.D.; Kong, X.M. Web-based tribology design repository system. Sci. China Ser. Math. Phys. Astron. 2001, 44, 483–488. [Google Scholar]

- Koschmann, T.; Evens, M.W. Bridging the gap between object-oriented and logic programming. IEEE Softw. 1988, 4, 36–42. [Google Scholar] [CrossRef] [Green Version]

- Xi, W.K.; Yuan, X.Y.; Jia, Q. Fundamentaal Tribology Knowledge Serve Modeling and Knowledge Resource Units Construction. In Fundamental Tribology Knowledge Serve Modeling and Knowledge Resource Units Construction; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2012. [Google Scholar] [CrossRef]

- Gruber, T.R. A translation approach to portable ontology specifications. Knowl. Acquis. 1993, 2, 199–220. [Google Scholar] [CrossRef]

- Harris, M.A.; Clark, J.; Ireland, A.; Lomax, J.; Ashburner, M.; Foulger, R.; Eilbeck, K.; Lewis, S.; Marshall, B.; Mungall, C.; et al. The Gene Ontology (GO) database and informatics resource. Nucleic Acids Res. 2004, 32, 258–261. [Google Scholar] [CrossRef] [Green Version]

- Malone, J.; Holloway, E.; Adamusiak, T.; Kapushesky, M.; Zheng, J.; Kolesnikov, N.; Zhukova, A.; Brazma, A.; Parkinson, H. Modeling sample variables with an Experimental Factor Ontology. Bioinformatics 2010, 8, 1112–1118. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Soldatova, L.N.; King, R.D. An ontology of scientific experiments. J. R. Soc. Interface 2006, 11, 795–803. [Google Scholar] [CrossRef] [Green Version]

- Niles, I.; Pease, A. Towards a standard upper ontology. In Proceedings of the International Conference on Formal Ontology in Information Systems, Ogunquit, ME, USA, 17–19 October 2001; ACM: New York, NY, USA, 2001; pp. 2–9. [Google Scholar] [CrossRef]

- Ogden, C.K.; Richards, I.A. The Meaning of Meaning: A Study of the Influence of Language upon Thought and of the Science of Symbolism; Trench, Trubner & Company, Limited: London, UK, 1923. [Google Scholar]

- Uschold, M.; Gruninger, M. Ontologies: Principles, methods and applications. Knowl. Eng. Rev. 1996, 2, 93–136. [Google Scholar] [CrossRef] [Green Version]

- Marian, M.; Song, G.-C.; Wang, B.; Fuenzalida, V.M.; Krauß, S.; Merle, B.; Tremmel, S.; Wartzack, S.; Yu, J.; Rosenkranz, A. Effective usage of 2D MXene nanosheets as solid lubricant – Influence of contact pressure and relative humidity. Unpublished manuscript, last modified 25th May 2020. Microsoft Word File.

- Marian, M.; Tremmel, S.; Wartzack, S.; Song, G.; Wang, B.; Yu, J.; Rosenkranz, A. Mxene nanosheets as an emerging solid lubricant for machine elements—Towards increased energy efficiency and service life. Appl. Surf. Sci. 2020, 523, 146503. [Google Scholar] [CrossRef]

- Zhang, D.; Ashton, M.; Ostadhossein, A.; van Duin, A.C.T.; Hennig, R.G.; Sinnott, S.B. Computational Study of Low Interlayer Friction in Tin+1Cn (n = 1, 2, and 3) MXene. ACS Appl. Mater. Interfaces 2017, 9, 34467–34479. [Google Scholar] [CrossRef]

- Chen, Z.; He, X.; Xiao, C.; Kim, S. Effect of Humidity on Friction and Wear—A Critical Review. Lubricants 2018, 6, 74. [Google Scholar] [CrossRef] [Green Version]

- OWL 2 Web Ontology Language Primer. Available online: http://www.w3.org/TR/owl2-primer/ (accessed on 26 June 2020).

- Musen, M.A. The Protégé Project: A Look Back and a Look Forward. AI Matters 2015, 4, 4–12. [Google Scholar] [CrossRef]

- Zhang, X.; Xue, M.; Yang, X.; Wang, Z.; Luo, G.; Huang, Z.; Sui, X.; Li, C. Preparation and tribological properties of Ti 3 C 2 (OH) 2 nanosheets as additives in base oil. RSC Adv. 2015, 4, 2762–2767. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, L.; Chen, Q.; Li, P.; Zhou, A.; Cao, X.; Hu, Q. Preparation, mechanical and anti-friction performance of MXene/polymer composites. Mater. Des. 2016, 92, 682–689. [Google Scholar] [CrossRef]

- SPARQL 1.1 query language. Available online: http://www.w3.org/TR/2013/REC-sparql11-query-20130321/(12.11.2018) (accessed on 26 June 2020).

- SPARQL 1.1 Update. Available online: http://www.w3.org/TR/2013/REC-sparql11-update-20130321/(12.11.2018) (accessed on 26 June 2020).

- Kestel, P.; Kügler, P.; Zirngibl, C.; Schleich, B.; Wartzack, S. Ontology-based approach for the provision of simulation knowledge acquired by Data and Text Mining processes. Adv. Eng. Inform. 2019, 39, 292–305. [Google Scholar] [CrossRef]

- Arndt, R.; Troncy, R.; Staab, S.; Hardman, L. COMM: A Core Ontology for Multimedia Annotation. In Handbook on Ontologies, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2009; pp. 403–422. [Google Scholar] [CrossRef]

- Alchourrón, C.E.; Gärdenfors, P.; Makinson, D. On the logic of theory change. J. Symb. Log. 1985, 2, 510–530. [Google Scholar] [CrossRef]

- Stachowiak, G.W.; Stachowiak, G.B.; Batchelor, A.W. Experimental Methods in Tribology, Transfered to Digital Printing 2007; Elsevier: Amsterdam, The Netherlands, 2007. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kügler, P.; Marian, M.; Schleich, B.; Tremmel, S.; Wartzack, S. tribAIn—Towards an Explicit Specification of Shared Tribological Understanding. Appl. Sci. 2020, 10, 4421. https://doi.org/10.3390/app10134421

Kügler P, Marian M, Schleich B, Tremmel S, Wartzack S. tribAIn—Towards an Explicit Specification of Shared Tribological Understanding. Applied Sciences. 2020; 10(13):4421. https://doi.org/10.3390/app10134421

Chicago/Turabian StyleKügler, Patricia, Max Marian, Benjamin Schleich, Stephan Tremmel, and Sandro Wartzack. 2020. "tribAIn—Towards an Explicit Specification of Shared Tribological Understanding" Applied Sciences 10, no. 13: 4421. https://doi.org/10.3390/app10134421