3D Strain Mapping of Opaque Materials Using an Improved Digital Volumetric Speckle Photography Technique with X-Ray Microtomography

Abstract

:1. Introduction

2. Methodology of Multi-Scale Subset and Subvoxel Shifting in DVSP

2.1. Theory of Multi-Scale Subset and Subvoxel Shifting in DVSP

2.2. X-ray Microtomography System and In Situ Loading Setup

3. Experiment and Results

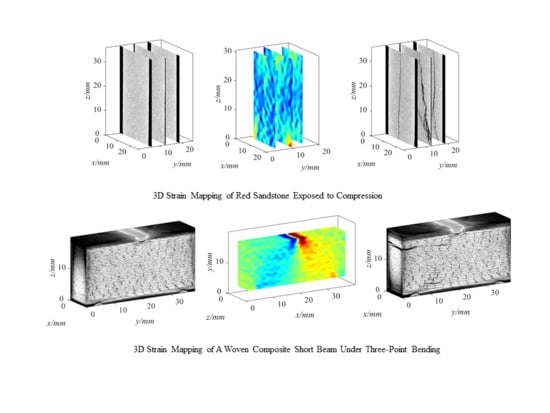

3.1. Internal Strain Investigation of Red Sandstone Exposed to Compression

3.2. A Woven Composite Short Beam Under Three-Point Bending

4. Discussion

4.1. Assessment of Accuracy of MS DVSP

4.2. Influence of Artifacts in CT Image

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Burch, J.M.; Tokarski, J.M.J. Production of multiple beam fringes from photographic scatters. Opt. Acta 1968, 15, 101–111. [Google Scholar] [CrossRef]

- Leendertz, J.A. Interferometric displacement measurements on scattering surface utilizing speckle effect. J. Phys. E 1970, 3, 214–218. [Google Scholar] [CrossRef]

- Chiang, F.P.; Asundi, A. White light speckle method of experimental strain analysis. Appl. Opt. 1979, 18, 409–411. [Google Scholar] [CrossRef] [PubMed]

- Chiang, F.P.; Jin, F. A new technique using digital speckle correlation for nondestructive inspection of corrosion. Mater. Eval. 1997, 55, 813–816. [Google Scholar]

- Chen, D.J.; Chiang, F.P. Computer-aided speckle interferometry using spectral amplitude fringes. Appl. Opt. 1993, 32, 225–236. [Google Scholar] [CrossRef] [PubMed]

- Chen, D.J.; Chiang, F.P.; Tan, Y.S.; Don, H.S. Digital speckle-displacement measurement using a complex spectrum method. Appl. Opt. 1993, 32, 1839–1849. [Google Scholar] [CrossRef] [PubMed]

- Chiang, F.P.; Asundi, A. Interior displacement and strain measurement using white light speckles. Appl. Opt. 1980, 19, 2254–2256. [Google Scholar]

- Burguete, R.L.; Patterson, E.A. A photoelastic study of contact between a cylinder and a half-space. Exp. Mech. 1997, 37, 314–323. [Google Scholar] [CrossRef]

- Ju, Y.; Xie, H.P.; Zheng, Z.M.; Lu, J.B.; Mao, L.T.; Gao, F.; Peng, R.D. Visualization of the complex structure and stress field inside rock by means of 3D printing technology. Chin. Sci. Bull. 2014, 59, 5354–5365. [Google Scholar] [CrossRef]

- Dupre, J.C.; Lagarde, A. Photoelastic analysis of a three-dimensional specimen by optical slicing and digital image processing. Exp. Mech. 1997, 37, 393–397. [Google Scholar] [CrossRef]

- Kihara, T. Whole-field measurement of three-dimensional stress by scattered-light photoelasticity with unpoparized light. In Proceedings of the 14th International Conference on Experimental Mechanics, Poitiers, France, 4–9 July 2010; p. 32006. [Google Scholar]

- Tomlison, R.A.; Patterson, E.A. The use of phase-stepping for the measurement of characteristic parameters in integrated photoelasticity. Exp. Mech. 2002, 42, 43–49. [Google Scholar] [CrossRef]

- Wijerathne, M.L.L.; Oguni, K.; Hori, M. Stress field tomography based on 3D photoelasticity. J. Mech. Phys. Solids 2008, 56, 1065–1085. [Google Scholar] [CrossRef]

- Aben, H.; Errapart, A. Photoelastic Tomography with linear and non-linear algorithms. Exp. Mech. 2012, 52, 1179–1193. [Google Scholar] [CrossRef]

- Sciammarella, C.A.; Chiang, F.P. The moiré method applied to three-dimensional elastic problems. Exp. Mech. 1964, 4, 313–319. [Google Scholar] [CrossRef]

- Chiang, F.P. A new three-dimensional strain analysis technique by scattered light speckle interferometry. In The Engineering Uses of Coherent Optics; Robertson, E.R., Ed.; Cambridge University Press: Cambridge, UK, 1976; pp. 249–262. [Google Scholar]

- Asundi, A.; Chiang, F.P. Theory and application of white light speckle methods. Opt. Eng. 1982, 21, 570–580. [Google Scholar] [CrossRef]

- Dudderar, T.D.; Simpkins, P.G. The development of scattered light speckle metrology. Opt. Eng. 1982, 21, 396–399. [Google Scholar] [CrossRef]

- Bay, B.K.; Smith, T.S.; Fyhie, D.P.; Saad, M. Digital volume correlation: Three-dimensional. strain mapping using X-ray tomography. Exp. Mech. 1999, 39, 217–226. [Google Scholar] [CrossRef]

- Forsberg, F.; Sjodahl, M.; Mooser, R.; Hack, E.; Wyss, P. Full three-dimensional strain measurements on wood exposed to three-point bending: Analysis by use of digital volume correlation applied to synchrotron radiation micro-computed tomography image data. Strain 2010, 46, 47–60. [Google Scholar] [CrossRef]

- Forsberg, F.; Siviour, C.R. 3D deformation and strain analysis in compacted sugar using x-ray microtomography and digital volume correlation. Meas. Sci. Technol. 2009, 20, 1–8. [Google Scholar] [CrossRef]

- Hall, S.A.; Bornert, M.; Desrues, J.; Pannier, Y.; Lenoir, N.; Viggiani, G.; Besuelle, P. Discrete and continuum analysis of localised deformation in sand using X-ray mCT and volumetric digital image correlation. Geotechnique 2010, 60, 315–322. [Google Scholar] [CrossRef]

- Rethore, J.; Limodin, N.; Buffiere, J.-Y.; Hild, F.; Ludwig, W.; Roux, S. Digital volume correlation analysis of synchrotron tomographic images. J. Strain Anal. Eng. 2011, 46, 683–695. [Google Scholar] [CrossRef]

- Lenoir, N.; Bornert, M.; Desrues, J.; Besuelle, P.; Viggiani, G. Volumetric digital image correlation applied to X-ray Microtomography images from triaxial compression tests on argillaceous rock. Strain 2007, 43, 193–205. [Google Scholar] [CrossRef]

- Renard, F.; McBeck, J.; Cordonnier, B.; Zheng, X.J.; KandulaJesus, N.; Sanchez, J.R.; Kobchenko, M.; Noiriel, C.; Zhu, W.L.; Meakin, P.; et al. Dynamic in situ three-dimensional imaging and digital volume correlation analysis to quantify strain localization and fracture coalescence in sandstone. Pure Appl. Geophys. 2018, 1–33. [Google Scholar] [CrossRef]

- McBeck, J.; Kobchenko, M.; Stephen, A.H.; Tudisco, E.; Cordonnier, B.; Meakin, P.; Renard, F. Investigating the Onset of Strain Localization within Anisotropic Shale Using Digital Volume Correlation of Time-Resolved X-Ray Microtomography Images. JGR Solid Earth 2018, 123, 7509–7528. [Google Scholar] [CrossRef]

- Chateau, C.; Nguyen, T.T.; Bornert, M.; Yvonnet, J. DVC-based image subtraction to detect microcracking in lightweight concrete. Strain 2017, 54. [Google Scholar] [CrossRef]

- Bennai, F.; Hachem, C.E.; Abahri, k.; Belarbi, R. Microscopic hydric characterization of hemp concrete by X-ray microtomography and digital volume correlation. Constr. Build. Mater. 2018, 188, 983–994. [Google Scholar] [CrossRef]

- Mendoza, A.; Schneiderc, J.; Parrab, E.; Obertb, E.; Rouxa, S. Differentiating 3D textile composites: A novel field of application for Digital Volume Correlation. Compos. Struct. 2019, 208, 735–743. [Google Scholar] [CrossRef]

- Gonzalez, J.F.; Antartis, D.A.; Martinez, M.; Dillon, S.J.; Chasiotis, I.; Lambros, J. Three-Dimensional Study of Graphite-Composite Electrode Chemo-Mechanical Response using Digital Volume Correlation. Exp. Mech. 2018, 58, 573–583. [Google Scholar] [CrossRef]

- Roux, S.; Hild, F.; Viot, P. Dominique Bernard. Three dimensional image correlation from X-Ray computed tomography of solid foam. Compos. Part A 2008, 39, 1253–1265. [Google Scholar] [CrossRef]

- Chiang, F.P.; Mao, L.T. Development of interior strain measurement techniques using random speckle patterns. Meccanica 2015, 50, 401–410. [Google Scholar] [CrossRef]

- Mao, L.T.; Zuo, J.P.; Yuan, Z.X.; Chiang, F.P. Full-field mapping of internal strain distribution in red sandstone specimen under compression using digital volumetric speckle photography and X-ray computed tomography. J. Rock Mech. Geotech. Eng. 2015, 7, 136–146. [Google Scholar] [CrossRef] [Green Version]

- Mao, L.T.; Chiang, F.P. 3D strain mapping in rocks using digital volumetric Speckle photography technique. Acta Mech. 2016, 227, 3069–3085. [Google Scholar] [CrossRef]

- Mao, L.T.; Hao, N.; An, L.Q.; Chiang, F.P.; Liu, H.B. 3D mapping of carbon dioxide-induced strain in coal using digital volumetric speckle photography technique and X-ray computer tomography. Int. J. Coal Geol. 2015, 147–148, 115–125. [Google Scholar] [CrossRef]

- Mao, L.T.; Yuan, Z.X.; Yang, M.; Liu, H.B.; Chiang, F.P. 3D strain evolution in concrete using in situ X-ray computed tomography testing and digital volumetric speckle photography. Measurement 2019, 133, 456–467. [Google Scholar] [CrossRef]

- Mao, L.T.; Chiang, F.P. Interior strain analysis of a woven composite beam using X-ray computed tomography and digital volumetric speckle photography. Compos. Struct. 2015, 134, 782–788. [Google Scholar] [CrossRef]

- Mao, L.T.; Chiang, F.P. Mapping interior deformation of a composite sandwich beam using Digital Volumetric Speckle Photography with X-ray computed tomography. Compos. Struct. 2017, 179, 172–180. [Google Scholar] [CrossRef]

- Mao, L.T.; Liu, H.Z.; Zhu, Z.Y.; Guo, R.; Zhu, Y.; Chiang, F.P. Digital volumetric speckle photography: A powerful experimental technique capable of quantifying interior deformation fields of composite materials. Multiscale Multidiscip. Model. Exp. Des. 2018, 1, 181–195. [Google Scholar] [CrossRef]

- Sjodahl, M. Accuracy in electronic speckle photography. Appl. Opt. 1997, 36, 2875–2885. [Google Scholar] [CrossRef] [PubMed]

- Perie, J.N.; Calloch, S.; Cluzel, C.; Hild, F. Analysis of a multiaxial test on a C/C composite by using digital image correlaiton and a damage model. Exp. Mech. 2002, 42, 318–418. [Google Scholar] [CrossRef]

- Bergonnier, S.; Hild, F.; Roux, S. Digital image correlation used for mechanical tests on crimped glass wool samples. J. Strain Anal. 2005, 40, 185–197. [Google Scholar] [CrossRef] [Green Version]

- Yang, M.; Liu, J.W.; Li, Z.C.; Liang, L.H.; Wang, X.L.; Gui, Z.G. Locating of 2π-projection view and projection denoising under fast continuous rotation scanning mode of micro-CT. Neurocomputing 2016, 207, 335–345. [Google Scholar] [CrossRef]

- Pan, B.; Qian, K.M.; Xie, H.M.; Asundi, A. Two-dimensional digital image correlation for in-plane displacement and strain measurement: A review. Meas. Sci. Technol. 2009, 20, 062001. [Google Scholar] [CrossRef]

- Hill, P.D. Kernel estimation of a distribution function. Commun. Stat. Theory Methods 1985, 14, 605–620. [Google Scholar] [CrossRef]

- Pan, B.; Wu, D.; Wang, Z. Internal displacement and strain measurement using digital volume correlation: A least-squares framework. Meas. Sci. Technol. 2012, 23, 045002. [Google Scholar] [CrossRef]

- Liu, X.Y.; Li, L.R.; Zhao, H.W.; Cheng, T.H.; Cui, G.J.; Tan, Q.C.; Meng, G.W. Quality assessment of speckle patterns for digital image correlation by Shannon entropy. Optik 2015, 126, 4206–4211. [Google Scholar] [CrossRef]

- Limodin, N.; Rethore, J.; Adrien, J.; Buffiere, J.Y.; Hild, F.; Roux, S. Analysis and artifact correction for volume correlation measurements using tomographic images from a laboratory X-ray source. Exp. Mech. 2011, 51, 959–970. [Google Scholar] [CrossRef]

- Wang, B.; Pan, B.; Lubineau, G. In-Situ Systematic Error Correction for Digital Volume Correlation Using a Reference Sample. Exp. Mech. 2018, 58, 427–436. [Google Scholar] [CrossRef]

- Pan, B. Thermal error analysis and compensation for digital image/volume correlation. Opt. Lasers Eng. 2018, 101, 1–15. [Google Scholar] [CrossRef]

- Buljac, A.; Jailin, C.; Mendoza, A.; Neggers, J.; Taillandier-Thomas, T.; Bouterf, A.; Smaniotto, B.; Hild, F.; Roux, S. Digital volume correlation: Review of progress and challenges. Exp. Mech. 2018, 58, 661–708. [Google Scholar] [CrossRef]

- Gates, M.; Lambros, J.; Heath, M.T. Towards high performance digital volume correlation. Exp. Mech. 2011, 51, 491–507. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mao, L.; Liu, H.; Zhu, Y.; Zhu, Z.; Guo, R.; Chiang, F.-p. 3D Strain Mapping of Opaque Materials Using an Improved Digital Volumetric Speckle Photography Technique with X-Ray Microtomography. Appl. Sci. 2019, 9, 1418. https://doi.org/10.3390/app9071418

Mao L, Liu H, Zhu Y, Zhu Z, Guo R, Chiang F-p. 3D Strain Mapping of Opaque Materials Using an Improved Digital Volumetric Speckle Photography Technique with X-Ray Microtomography. Applied Sciences. 2019; 9(7):1418. https://doi.org/10.3390/app9071418

Chicago/Turabian StyleMao, Lingtao, Haizhou Liu, Ying Zhu, Ziyan Zhu, Rui Guo, and Fu-pen Chiang. 2019. "3D Strain Mapping of Opaque Materials Using an Improved Digital Volumetric Speckle Photography Technique with X-Ray Microtomography" Applied Sciences 9, no. 7: 1418. https://doi.org/10.3390/app9071418