An Elastic Interface Model for the Delamination of Bending-Extension Coupled Laminates

Abstract

:1. Introduction

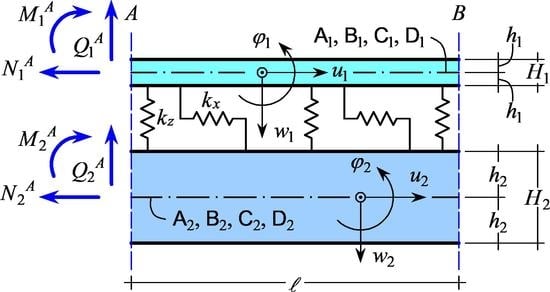

2. Crack-Tip Element

2.1. Mechanical Model

2.2. Differential Problem

2.3. Boundary Conditions

3. Solution of the Differential Problem

3.1. Solution Strategy

3.2. Balanced Case

3.2.1. Interfacial Stresses

3.2.2. Internal Forces

3.2.3. Strain Measures

3.2.4. Generalized Displacements

3.2.5. Supernumerary Integration Constants

3.3. Unbalanced Case

3.3.1. Interfacial Stresses

3.3.2. Internal Forces

3.3.3. Strain Measures

3.3.4. Generalized Displacements

3.3.5. Supernumerary Integration Constants

4. Delamination Crack Analysis

4.1. Energy Release Rate

5. Results

5.1. Examples

- UD//UD

- UD//CP

- UD//MD

5.2. Effects of Interface Stiffness

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| CTE | crack-tip element |

| CP | cross-ply |

| DCB | double cantilever beam |

| DCB-UBM | double cantilever beam with uneven bending moments |

| LEFM | linear elastic fracture mechanics |

| MD | multi-directional |

| UD | uni-directional |

Appendix A. Laminated Beam Stiffnesses

Appendix A.1. Extension and Bending Stiffnesses

Appendix A.2. Shear Stiffness

Appendix B. Properties of Characteristic Equation Roots

Appendix B.1. Balanced Case

Appendix B.2. Unbalanced Case

Appendix C. -Integral Calculation for the Crack-Tip Element

| Path Segment | u | w | |||||

|---|---|---|---|---|---|---|---|

| 0 | - | ||||||

| u | w | ||||||

| 0 | − | - |

References

- Talreja, R.; Singh, C.V. Damage and Failure of Composite Materials; Cambridge University Press: Cambridge, UK, 2012; ISBN 978-0-521-81942-8. [Google Scholar]

- Garg, A.C. Delamination—A damage mode in composite structures. Eng. Fract. Mech. 1988, 29, 557–584. [Google Scholar] [CrossRef]

- Bolotin, V.V. Delaminations in composite structures: its origin, buckling, growth and stability. Compos. Part B Eng. 1996, 27, 129–145. [Google Scholar] [CrossRef]

- Tay, T.E. Characterization and analysis of delamination fracture in composites: An overview of developments from 1990 to 2001. Appl. Mech. Rev. 2003, 56, 1–31. [Google Scholar] [CrossRef]

- Senthil, K.; Arockiarajan, A.; Palaninathan, R.; Santhosh, B.; Usha, K.M. Defects in composite structures: Its effects and prediction methods—A comprehensive review. Compos. Struct. 2013, 106, 139–149. [Google Scholar] [CrossRef]

- Tabiei, A.; Zhang, W. Composite Laminate Delamination Simulation and Experiment: A Review of Recent Development. Appl. Mech. Rev. 2018, 70, 030801. [Google Scholar] [CrossRef]

- Bucur, V. (Ed.) Delamination in Wood, Wood Products and Wood-Based Composites; Springer: Dordrecht, The Netherlands, 2011; ISBN 978-90-481-9549-7. [Google Scholar] [CrossRef]

- Minatto, F.D.; Milak, P.; De Noni, A.; Hotza, D.; Montedo, O.R.K. Multilayered ceramic composites—A review. Adv. Appl. Ceram. 2015, 114, 127–138. [Google Scholar] [CrossRef]

- Friedrich, K. (Ed.) Application of Fracture Mechanics to Composite Materials; Elsevier: Amsterdam, The Netherlands, 1989; ISBN 978-0-444-87286-9. [Google Scholar]

- Carlsson, L.A.; Adams, D.F.; Pipes, R.B. Experimental Characterization of Advanced Composite Materials, 4th ed.; CRC Press: Boca Raton, FL, USA, 2014; ISBN 978-1-4398-4858-6. [Google Scholar]

- Hutchinson, J.W.; Suo, Z. Mixed mode cracking in layered materials. Adv. Appl. Mech. 1991, 29, 63–191. [Google Scholar] [CrossRef]

- Kanninen, M.F. An augmented double cantilever beam model for studying crack propagation and arrest. Int. J. Fract. 1973, 9, 83–92. [Google Scholar] [CrossRef]

- Bruno, D.; Grimaldi, A. Delamination failure of layered composite plates loaded in compression. Int. J. Solids Struct. 1990, 26, 313–330. [Google Scholar] [CrossRef]

- Allix, O.; Ladevèze, P. Interlaminar interface modeling for the prediction of delamination. Compos. Struct. 1992, 22, 235–242. [Google Scholar] [CrossRef]

- Corigliano, A. Formulation, identification and use of interface models in the numerical analysis of composite delamination. Int. J. Solids Struct. 1993, 30, 2779–2811. [Google Scholar] [CrossRef]

- Allix, O.; Ladevèze, P.; Corigliano, A. Damage analysis of interlaminar fracture specimens. Compos. Struct. 1995, 31, 61–74. [Google Scholar] [CrossRef]

- Point, N.; Sacco, E. A delamination model for laminated composites. Int. J. Solids Struct. 1996, 33, 483–509. [Google Scholar] [CrossRef]

- Bruno, D.; Greco, F. Mixed mode delamination in plates: a refined approach. Int. J. Solids Struct. 2001, 38, 9149–9177. [Google Scholar] [CrossRef]

- Qiao, P.; Wang, J. Mechanics and fracture of crack tip deformable bi-material interface. Int. J. Solids Struct. 2004, 41, 7423–7444. [Google Scholar] [CrossRef]

- Szekrényes, A. Improved analysis of unidirectional composite delamination specimens. Mech. Mater. 2007, 39, 953–974. [Google Scholar] [CrossRef]

- Bennati, S.; Valvo, P.S. Delamination growth in composite plates under compressive fatigue loads. Compos. Sci. Technol. 2006, 66, 248–254. [Google Scholar] [CrossRef]

- Bennati, S.; Colleluori, M.; Corigliano, D.; Valvo, P.S. An enhanced beam-theory model of the asymmetric double cantilever beam (ADCB) test for composite laminates. Compos. Sci. Technol. 2009, 69, 1735–1745. [Google Scholar] [CrossRef]

- Bennati, S.; Fisicaro, P.; Valvo, P.S. An enhanced beam-theory model of the mixed-mode bending (MMB) test—Part I: Literature review and mechanical model. Meccanica 2013, 48, 443–462. [Google Scholar] [CrossRef]

- Bennati, S.; Fisicaro, P.; Valvo, P.S. An enhanced beam-theory model of the mixed-mode bending (MMB) test—Part II: Applications and results. Meccanica 2013, 48, 465–484. [Google Scholar] [CrossRef]

- Xie, J.; Waas, A.; Rassaian, M. Analytical predictions of delamination threshold load of laminated composite plates subject to flexural loading. Compos. Struct. 2017, 179, 181–194. [Google Scholar] [CrossRef]

- Dimitri, R.; Tornabene, F.; Zavarise, G. Analytical and numerical modeling of the mixed-mode delamination process for composite moment-loaded double cantilever beams. Compos. Struct. 2018, 187, 535–553. [Google Scholar] [CrossRef]

- Park, K.; Paulino, G.H. Cohesive Zone Models: A Critical Review of Traction-Separation Relationships Across Fracture Surfaces. Appl. Mech. Rev. 2013, 64, 060802. [Google Scholar] [CrossRef]

- Dimitri, R.; Trullo, M.; De Lorenzis, L.; Zavarise, G. Coupled cohesive zone models for mixed-mode fracture: A comparative study. Eng. Fract. Mech. 2015, 148, 145–179. [Google Scholar] [CrossRef]

- Borg, R.; Nilsson, L.; Simonsson, K. Simulation of delamination in fiber composites with a discrete cohesive failure model. Compos. Sci. Technol. 2001, 61, 667–677. [Google Scholar] [CrossRef]

- Camanho, P.P.; Dávila, C.G.; de Moura, M.F. Numerical simulation of mixed-mode progressive delamination in composite materials. J. Compos. Mater. 2003, 37, 1415–1438. [Google Scholar] [CrossRef]

- Yang, Q.; Cox, B. Cohesive models for damage evolution in laminated composites. Int. J. Fract. 2005, 133, 107–137. [Google Scholar] [CrossRef]

- Parmigiani, J.P.; Thouless, M.D. The effects of cohesive strength and toughness on mixed-mode delamination of beam-like geometries. Eng. Fract. Mech. 2007, 74, 2675–2699. [Google Scholar] [CrossRef] [Green Version]

- Turon, A.; Dávila, C.G.; Camanho, P.P.; Costa, J. An engineering solution for mesh size effects in the simulation of delamination using cohesive zone models. Eng. Fract. Mech. 2007, 74, 1665–1682. [Google Scholar] [CrossRef]

- Harper, P.W.; Hallett, S.R. Cohesive zone length in numerical simulations of composite delamination. Eng. Fract. Mech. 2008, 75, 4774–4792. [Google Scholar] [CrossRef] [Green Version]

- Sørensen, B.F.; Jacobsen, T.K. Characterizing delamination of fiber composites by mixed mode cohesive laws. Compos. Sci. Technol. 2009, 69, 445–456. [Google Scholar] [CrossRef]

- Xie, J.; Waas, A.; Rassaian, M. Closed-form solutions for cohesive zone modeling of delamination toughness tests. Int. J. Solids Struct. 2016, 88–89, 379–400. [Google Scholar] [CrossRef]

- Wu, C.; Gowrishankar, S.; Huang, R.; Liechti, K.M. On determining mixed-mode traction–separation relations for interfaces. Int. J. Fract. 2016, 202, 1–19. [Google Scholar] [CrossRef]

- Wu, C.; Huang, R.; Liechti, K.M. Simultaneous extraction of tensile and shear interactions at interfaces. J. Mech. Phys. Solids 2019, 125, 225–254. [Google Scholar] [CrossRef]

- Da Silva, L.F.M.; das Neves, P.J.C.; Adams, R.D.; Spelt, J.K. Analytical models of adhesively bonded joints—Part I: Literature survey. Int. J. Adhes. Adhes. 2009, 29, 319–330. [Google Scholar] [CrossRef]

- Bigwood, D.A.; Crocombe, A.D. Elastic analysis and engineering design formulae for bonded joints. Int. J. Adhes. Adhes. 1989, 9, 229–242. [Google Scholar] [CrossRef]

- Krenk, S. Energy release rate of symmetric adhesive joints. Eng. Fract. Mech. 1992, 43, 549–559. [Google Scholar] [CrossRef]

- Penado, F.E. A closed form solution for the energy release rate of the double cantilever beam specimen with an adhesive layer. J. Compos. Mater. 1993, 27, 383–407. [Google Scholar] [CrossRef]

- Bennati, S.; Taglialegne, L.; Valvo, P.S. Modelling of interfacial fracture of layered structures. In Proceedings of the ECF 18—18th European Conference on Fracture, Dresden, Germany, 30 August–3 September 2010; ISBN 978-3-00-031802-3. [Google Scholar]

- Liu, Z.; Huang, Y.; Yin, Z.; Bennati, S.; Valvo, P.S. A general solution for the two-dimensional stress analysis of balanced and unbalanced adhesively bonded joints. Int. J. Adhes. Adhes. 2014, 54, 112–123. [Google Scholar] [CrossRef] [Green Version]

- Jiang, W.; Qiao, P. An improved four-parameter model with consideration of Poisson’s effect on stress analysis of adhesive joints. Eng. Struct. 2015, 88, 203–215. [Google Scholar] [CrossRef]

- Zhang, Z.W.; Li, Y.S.; Liu, R. An analytical model of stresses in adhesive bonded interface between steel and bamboo plywood. Int. J. Solids Struct. 2015, 52, 103–113. [Google Scholar] [CrossRef]

- Blackman, B.R.K.; Hadavinia, H.; Kinloch, A.J.; Williams, J.G. The use of a cohesive zone model to study the fracture of fiber composites and adhesively-bonded joints. Int. J. Fract. 2003, 119, 25–46. [Google Scholar] [CrossRef]

- Li, S.; Thouless, M.D.; Waas, A.M.; Schroeder, J.A.; Zavattieri, P.D. Mixed-mode cohesive-zone models for fracture of an adhesively bonded polymer—Matrix composite. Eng. Fract. Mech. 2006, 73, 64–78. [Google Scholar] [CrossRef]

- Jones, R.M. Mechanics of Composite Materials, 2nd ed.; Taylor & Francis Inc.: Philadelphia, PA, USA, 1999; ISBN 978-1560327127. [Google Scholar]

- Schapery, R.A.; Davidson, B.D. Prediction of energy release rate for mixed-mode delamination using classical plate theory. Appl. Mech. Rev. 1990, 43, S281–S287. [Google Scholar] [CrossRef]

- Valvo, P.S. On the calculation of energy release rate and mode mixity in delaminated laminated beams. Eng. Fract. Mech. 2016, 165, 114–139. [Google Scholar] [CrossRef]

- Tsokanas, P.; Loutas, T. Hygrothermal effect on the strain energy release rates and mode mixity of asymmetric delaminations in generally layered beams. Eng. Fract. Mech. 2019, 214, 390–409. [Google Scholar] [CrossRef]

- Taglialegne, L. Modellazione Meccanica Della Frattura Interlaminare di Provini in Composito Non Simmetrici. Master’s Thesis, University of Pisa, Pisa, Italy, 2014. Available online: http://etd.adm.unipi.it/theses/available/etd-09172014-092832 (accessed on 23 July 2019).

- Davidson, B.D.; Hu, H.; Schapery, R.A. An Analytical Crack-Tip Element for Layered Elastic Structures. J. Appl. Mech. 1995, 62, 294–305. [Google Scholar] [CrossRef]

- Wang, J.; Qiao, P. Interface crack between two shear deformable elastic layers. J. Mech. Phys. Solids 2004, 52, 891–905. [Google Scholar] [CrossRef]

- Timoshenko, S.P. Strength of Materials, Vol. 1: Elementary Theory And Problems, 3rd ed.; D. Van Nostrand: New York, NY, USA, 1955; ISBN 978-0442085414. [Google Scholar]

- Rice, J.R. A path independent integral and the approximate analysis of strain concentrations by notches and cracks. J. Appl. Mech. 1968, 35, 379–386. [Google Scholar] [CrossRef]

- Arouche, M.M.; Wang, W.; Teixeira de Freitas, S.; de Barros, S. Strain-based methodology for mixed-Mode I+II fracture: A new partitioning method for bi-material adhesively bonded joints. J. Adhes. 2019, 95, 385–404. [Google Scholar] [CrossRef]

- Vannucci, P.; Verchery, G. A special class of uncoupled and quasi-homogeneous laminates. Compos. Sci. Technol. 2001, 61, 1465–1473. [Google Scholar] [CrossRef]

- Garulli, T.; Catapano, A.; Fanteria, D.; Jumel, J.; Martin, E. Design and finite element assessment of fully uncoupled multi-directional layups for delamination tests. J. Compos. Mater. 2019. [Google Scholar] [CrossRef]

- Samborski, S. Numerical analysis of the DCB test configuration applicability to mechanically coupled Fiber Reinforced Laminated Composite beams. Compos. Struct. 2016, 152, 477–487. [Google Scholar] [CrossRef]

- Bennati, S.; Valvo, P.S. An experimental compliance calibration strategy for mixed-mode bending tests. Proc. Mater. Sci. 2014, 3, 1988–1993. [Google Scholar] [CrossRef]

- Sørensen, B.F.; Jørgensen, K.; Jacobsen, T.K.; Østergaard, R.C. DCB-specimen loaded with uneven bending moments. Int. J. Fract. 2006, 141, 163–176. [Google Scholar] [CrossRef]

- Davidson, B.D.; Gharibian, S.J.; Yu, L. Evaluation of energy release rate-based approaches for predicting delamination growth in laminated composites. Int. J. Fract. 2000, 105, 343–365. [Google Scholar] [CrossRef]

- Davidson, B.D.; Bialaszewski, R.D.; Sainath, S.S. A non-classical, energy release rate based approach for predicting delamination growth in graphite reinforced laminated polymeric composites. Compos. Sci. Technol. 2006, 66, 1479–1496. [Google Scholar] [CrossRef]

- Harvey, C.M.; Wang, S. Experimental assessment of mixed-mode partition theories. Compos. Struct. 2012, 94, 2057–2067. [Google Scholar] [CrossRef]

- Harvey, C.M.; Eplett, M.R.; Wang, S. Experimental assessment of mixed-mode partition theories for generally laminated composite beams. Compos. Struct. 2015, 124, 10–18. [Google Scholar] [CrossRef] [Green Version]

- Bednarcyk, B.A.; Aboudi, J.; Yarrington, P.W.; Collier, C.S. Simplified Shear Solution for Determination of the Shear Stress Distribution in a Composite Panel From the Applied Shear Resultant. In Proceedings of the 49th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Schaumburg, IL, USA, 7–10 April 2008. [Google Scholar] [CrossRef]

- Kumar, R.; Nath, J.K.; Pradhan, M.K.; Kumar, R. Analysis of Laminated Composite Using Matlab. In Proceedings of the ICMEET 2014—1st International Conference on Mechanical Engineering: Emerging Trends for Sustainability, MANIT, Bhopal, India, 29–31 January 2014. [Google Scholar]

- Wallner-Novak, M.; Augustin, M.; Koppelhuber, J.; Pock, K. Cross-Laminated Timber Structural Design; proHolz: Vienna, Austria, 2018; Volume II, ISBN 978-3-902320-96-4. [Google Scholar]

| (MPa) | (MPa) | – | – | (MPa) | (MPa) |

|---|---|---|---|---|---|

| 109,000 | 8819 | 0.342 | 0.380 | 4315 | 3200 |

| Sublaminate | Stacking Sequence |

|---|---|

| UD | |

| CP | |

| MD |

| Sublaminate | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| (N/mm) | (N) | (N mm) | |||||||

| 176,066 | 4872 | 0 | 0 | 0 | 0 | 37,561 | 1039 | 0 | |

| UD | 4872 | 14,245 | 0 | 0 | 0 | 0 | 1039 | 3039 | 0 |

| 0 | 0 | 6904 | 0 | 0 | 0 | 0 | 0 | 1473 | |

| 95,156 | 4872 | 0 | 8091 | 0 | 0 | 25,155 | 1039 | 0 | |

| CP | 4872 | 95,156 | 0 | 0 | −8091 | 0 | 1039 | 15,445 | 0 |

| 0 | 0 | 6904 | 0 | 0 | 0 | 0 | 0 | 1473 | |

| 66,477 | 33,550 | 0 | 10,959 | −2868 | 0 | 19,419 | 6775 | 0 | |

| MD | 33,550 | 66,477 | 0 | −2868 | −5223 | 0 | 6775 | 9710 | 0 |

| 0 | 0 | 35,582 | 0 | 0 | −2868 | 0 | 0 | 7209 |

| Sublaminate | ||||

|---|---|---|---|---|

| (kN) | (kN mm) | (kN) | (kN mm2) | |

| UD | 4360.0 | 0 | 143.8 | 930.1 |

| CP | 2372.4 | 201.5 | 129.0 | 627.0 |

| MD | 1238.5 | 314.2 | 123.8 | 367.0 |

| Specimen | ||||

|---|---|---|---|---|

| (J/m2) | (J/m2) | (J/m2) | (deg) | |

| UD//UD | 339.7 | 0 | 339.7 | 0 |

| UD//CP | 403.4 | 11.4 | 414.8 | −9.5 |

| UD//MD | 524.2 | 135.9 | 660.1 | −27.0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bennati, S.; Fisicaro, P.; Taglialegne, L.; Valvo, P.S. An Elastic Interface Model for the Delamination of Bending-Extension Coupled Laminates. Appl. Sci. 2019, 9, 3560. https://doi.org/10.3390/app9173560

Bennati S, Fisicaro P, Taglialegne L, Valvo PS. An Elastic Interface Model for the Delamination of Bending-Extension Coupled Laminates. Applied Sciences. 2019; 9(17):3560. https://doi.org/10.3390/app9173560

Chicago/Turabian StyleBennati, Stefano, Paolo Fisicaro, Luca Taglialegne, and Paolo S. Valvo. 2019. "An Elastic Interface Model for the Delamination of Bending-Extension Coupled Laminates" Applied Sciences 9, no. 17: 3560. https://doi.org/10.3390/app9173560