1. Introduction

Pneumatic technology, a good terminal energy use system, has been widely used in various fields of industry because of the advantages of low cost, high power-to-weight ratio, non-pollution and energy saving [

1,

2,

3,

4]. In recent years, with the development of microelectronic technology and the emergence of high-performance pneumatic components, pneumatic servo systems have been developed rapidly [

5]. However, in some special cases, such as pneumatic manipulators for welding and feeding operations, gas floating vibration isolation optical platforms and medical assisted robots, precision control of pneumatic actuator is of particular importance [

6].

Intelligent control based on a complex model follows the traditional thinking of electromechanical system research, which has been understood and used by researchers. In previous studies [

7,

8,

9], the valve-controlled actuator system model was usually linearized to a third-order transfer function by the method of intermediate position linearization. This type of linearized model is simple in structure, and the system accuracy often depends on the control effect of the intelligent algorithm. The non-linear characteristics and model uncertainty of a pneumatic system are the main factors that restrict the control accuracy of the pneumatic servo system and also make the classical control method based on linear theory gradually fail to meet the high performance requirements of the system. Therefore, it is urgent to establish a more accurate non-linear model based on the non-linear characteristics of the pneumatic servo system [

10,

11].

A pneumatic servo system has strong non-linear model characteristics, such as proportional valve flow non-linearity, differential equation non-linearity and actuator friction non-linearity. All these can affect the accuracy of the pneumatic servo system. The non-linear flow of a proportional directional control valve is the most important non-linearity. In papers [

12,

13], the mass flow characteristic was stated by taking into account the sonic conductance

and critical pressure ratio

which are from the international standard ISO 6358. These two characteristic values can be measured by measuring the flow rate and differential pressure of compressed air flowing through the measured components. However, the effective area of the proportional valve orifice has not been derived from the physical area. Rad et al. [

14] proposed an accurate mathematical model of a proportional directional control valve by considering the influence of dead-zone volume of proportional valve, and verified that using dead-zone volume can improve the accuracy of the model. However, the dead-zone characteristics are not obvious in a low-flow proportional valve, thus it is difficult to accurately characterize the mass flow equation of proportional valve. Actually, there are clearances between the spool and the sleeve of a proportional directional control valve, which would change the physical area of orifice directly and affect the accuracy of the proportional valve. Therefore, the influence of clearances should to be taken into account to restate the mass flow rate of a proportional directional control valve.

There are three ways as follows to derive energy equation of a chamber [

15]: (1) by the adiabatic process (2) by the isothermal process and (3) by taking into account a heat transfer formula after the heat transfer coefficient between the gas and inner wall is taken as a constant. During the adiabatic process, the gas temperature in a chamber increases continuously when charged, decreases continuously when discharged, and is stable in the isothermal process. Hence, the first two methods are both in contradiction with the actual phenomenon, which reduces the accuracy of the model to a certain extent. Valdiero et al. [

16] established a non-linear model of a pneumatic servo system in which the pressure differential equation of the cylinder is derived from the law of conservation of energy, and the method is well verified by experiments. However, the temperature differential equation was not found to reveal the temperature change of the gas. In the paper [

14], heat exchange between gas and the outside was considered in the modeling of the pneumatic system, and the heat transfer coefficient was identified by pneumatic circuits; however, the temperature variation was not verified with the experiment. Therefore, heat transfer can further improve the accuracy of the actuator model.

In addition, friction non-linearity is also one of the key factors that affect the accuracy of the system. Especially for high-precision testing equipment such as a pneumatic servo turntable, low-speed performance is one of the core indexes. For example, in the low-speed stage, the friction phenomenon prevails and whose impacts on the servo system are the most obvious [

17]. The Stribeck model can well describe the friction behavior at low speed, and has been widely used in current position control systems [

18]. Kong et al. [

19] applied a simplified Stribeck model to the mathematical model of a valve-controlled cylinder and achieved a good control effect by means of the friction chatter-compensation. The experiment verified that the friction model used is suitable for the control design of the system. Zhang et al. [

20] considered the Stribeck effect on the modeling of a rodless cylinder, and the results of experiments and simulation show that the non-linear model obtained can better reflect the characteristics of the pneumatic position servo system than previous research. Hence, we can apply the Stribeck model to the friction model of a pneumatic rack and pinion rotary actuator to better show the non-linearity of friction.

After accurately establishing the model, the values of model parameters will affect the control results of the system. The accuracy of parameters can be improved by using high-precision sensors and reasonable testing methods. Flow sensors FESTO SFAH and FESTO SFAB can be used to measure mass flow accurately. A pressure transmitter and temperature transmitter are highly accurate and have high real-time performance.

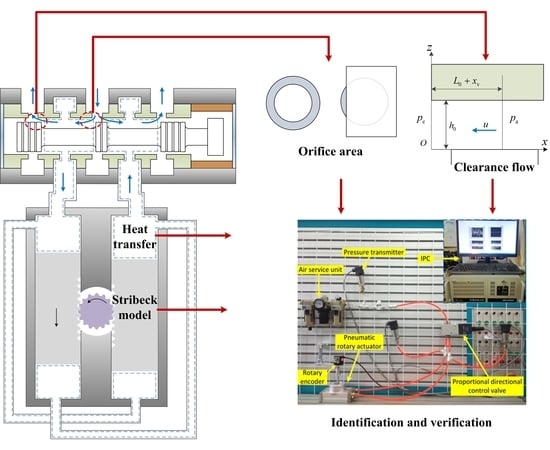

In this paper, in order to build the non-linear model of a pneumatic rotary actuator position servo system accurately, the mass flow rate of the gas flowing through each valve port of the proportional directional control valve was derived by taking into account the influence of clearances between the valve spool and sleeve, the heat transfer formula was taken into the energy equation of the system, and the Stribeck model was used in the friction model of the pneumatic rotary actuator. Then, the established non-linear model and pneumatic test circuits were applied to the identification of the flow coefficient, heat transfer coefficient and friction parameters. Finally, the charging and discharging experiment and the model verification experiment were carried out to verify the accuracy of the non-linear model. The results show that the simulation curves of the rotation angle and two chamber pressures are consistent with the experimental curves. The established non-linear model can accurately reflect the characteristics and the motion states of the pneumatic rotary actuator position servo system. The results of the study are important for the theory and practice of pneumatic servo systems.

3. Mass Flow Rates of the Proportional Direction Control Valve

As shown in

Figure 3, the right and left chambers of the proportional directional control valve are respectively connected to the two chambers of the pneumatic rotary actuator, and the air flow between them is unimpeded. Therefore, one of the proportional valve chambers and the connected actuator chamber can be regarded as a common whole which is also known as a control body where the gas temperature and pressure are evenly distributed, and the control bodies are represented by dashed lines. We can set the left control body as chamber

a, and another control body chamber

b.

The movement of the proportional direction control valve will generate clearance or an orifice at each valve port. At port 1, because of the existence of clearance, the gas will flow to the left chamber and the right chamber at the same time. In most studies, the gas flow generated by the clearance is often neglected, which also affects the control accuracy of the system. Therefore, we derive the mass flow rates of the gas flowing through clearance and the orifice, respectively, to make the model more accurate.

3.1. Gas Flow Mechanism in the Proportional Direction Control Valve

It is assumed that the direction of the proportional valve moving to the right is the positive direction, then the displacement of the spool is positive, and

. As shown in

Figure 4, for the left chamber, the movement of the spool makes port 5 a clearance and port 1 a throttle. For the right chamber, port 1 forms a clearance, and port 3 a throttle. At port 1, most of the gas flows through the orifice to the left chamber, and a small portion of the gas flows through the clearance to the right chamber.

The gas flow process of the left chamber is that the compressed air at port 1 flows through the orifice and then into the left chamber; the gas in the left chamber flows through the clearance of port 5 and then into the atmosphere. Since the volume of the proportional valve chamber is much smaller than that of the actuator chamber, the mass change rate

of the gas in chamber

a is equal to the mass flow rate

at port 4, which can be expressed by Equation (1).

where

is the mass flow rate of the gas flowing from port 1 to chamber

a, and

is the mass flow rate of the gas flowing through port 5.

The gas flow process of the right chamber is that the compressed air at port 1 flows through the clearance and then into the right chamber; the gas in the right chamber flows through the orifice of port 3 and then into the atmosphere. The mass change rate

of the gas in chamber

b is equal to the mass flow rate

at port 2, and can be expressed by Equation (2).

where

is the mass flow rate of the gas flowing from port 1 to chamber

b, and

is the mass flow rate of the gas flowing through port 3.

3.2. Mass Flow Rates of the Gas Flowing through the Orifices

In

Figure 5, the sleeve of the proportional valve has two symmetrical circular holes in the same vertical direction. The gas flows through both two circular holes into chambers or the atmosphere. When the spool moves to the right, the spool shoulder covers two holes to form the two same orifices in the same vertical direction.

In

Figure 5, because of the existence of the clearance, the mass flow rate

can be regarded as the scaled value of two mass flow rates in the horizontal and vertical directions. Correspondingly, the orifice has a physical area in each direction. The shadow area

represents the physical area of the orifice in the vertical direction and the shadow area

represents the physical area of the orifice in the horizontal direction. The effective area

of the orifice can be assumed as follows:

where

is the flow coefficient of the orifice, which is necessary because there is pressure loss when the gas passes through the orifice;

represents the physical area of the orifice; and

is an assumed coefficient to realize the area conversion from horizontal direction to vertical direction. Both

and

can be obtained by calculation. Even if the spool displacement is changed, the clearance area and shape in the horizontal direction are constant. Therefore, the influence of

on

can be regarded as constant, that is,

can be regarded as a fixed value. When the spool is in the middle position,

. After that, the value of

can be solved. Substituting the value of

into Equation (3) yields the value of

, and then

can be obtained. However,

changes with the position of the spool, and the expression of

can be obtained by test.

In addition, the effective area of the orifice at port 3 is equal to the effective area of the orifice at port 1.

Figure 6a shows the relative position of the circular hole and the spool shoulder when the proportional valve spool is in the initial position.

Figure 6b shows the relative position when the displacement of the spool is

. Moreover, circle center

is the origin of the coordinate.

is the radius of the circular hole.

represents the displacement of the spool, and the width of the spool shoulder is

.

Then, we can obtain the physical area

from their geometric relations.

Figure 7 shows the physical area of the orifice in the horizontal direction, where

represents the length of the clearance,

is the diameter of the spool shoulder, and

represents the inner diameter of the sleeve. It is easy to obtain Equations (5) and (6):

Therefore, the effective area of the orifice can be obtained by Equations (3)–(5).

It is assumed that the gas flowing through the orifice has no time to exchange heat with the outside and has no friction loss, hence it can be considered as an isentropic adiabatic process [

21]. According to the research by Sanville. F. E. [

22], the mass flow rates of the gas flowing through the orifices can be described by the following equations.

where

is the supply pressure,

and

represent the pressures of chamber

a and

b, respectively, and

is atmospheric pressure.

represents the supply temperature,

represents the temperature of the gas in chamber

b,

is the gas constant,

is the critical pressure ratio, and

is isentropic index. The isentropic index exists in the isentropic process and is equal to the ratio of the heat capacity at constant pressure to heat capacity at constant volume. The isentropic index of air at room temperature is 1.4.

3.3. Mass Flow Rates of the Gas Flowing through the Clearances

The flow of the gas flowing through the clearance is similar to the flow of viscous fluid between the parallel plates [

23].

Figure 8 is the schematic diagram of the clearance flow at port 5, when the spool moves to the right. The initial length of the clearance is

. Referring to the equation of the clearance flow between two parallel plates, we can get the differential equation of the gas pressure.

where

is the pressure of the gas micelle in the clearance,

is the viscosity coefficient of the gas, and

is the velocity of the gas micelles in the horizontal direction.

The boundary conditions are:

and

According to the boundary condition Equation (11), the equation of the airflow velocity varying with

can be obtained by solving Equation (10).

The mass flow rate of the gas flowing through the clearance is

where

is atmospheric density.

The size of the plate clearance is constant in the direction of the

axis, so the change rate of

along the

axis decreases uniformly. Therefore, combined with the boundary condition Equation (12),

The ideal gas law is

, where

is gas density, and

is gas temperature. The gas velocity in the clearance is very low, and the gas exchanges heat with the outside sufficiently. Hence, the state change of the gas in the clearance can be regarded approximately as an isothermal process:

After substituting Equations (6), (13), (15) and (16) into Equation (14), we obtain

Similarly, the mass flow rate

can also be obtained using the above principle.

3.4. Mass Flow Rates When the Spool Moves Backward

When the spool moves to the left,

. As shown in

Figure 9, the gas flowing from port 1 to the right chamber and the gas flowing from the left chamber to atmosphere are throttled flow. The gas flowing from port 1 to the left chamber and the gas flowing from the right chamber to the atmosphere are clearance flow. Their mass flow rates are represented by

,

,

,

,

and

, respectively, and they still have the following relationships.

The physical area of the orifice can be expressed as

The mass flow rates of the gas flowing through the orifices can be rewritten as

where

is the temperature of the gas in chamber

a.

The mass flow rates of the gas flowing through the clearances are as follows: