Maritime Transport in a Life Cycle Perspective: How Fuels, Vessel Types, and Operational Profiles Influence Energy Demand and Greenhouse Gas Emissions

Abstract

:1. Introduction

2. Materials and Methods

2.1. System Description: Vessel, Engine and Fuel Types

- The fuel type affects the cargo capacity. The higher bunker storage requirement for LNG decreases the cargo capacity for the container vessel and the ferry by 1.8% and 4%, respectively [23,47]. In the case of the tanker and the cruise vessel, the cargo/passenger capacity is not affected by the choice of fuel. For the former, the LNG is stored in an external tank transported on the deck of the vessel [48], while for the latter it is assumed that in new vessels the space loss is counterbalanced by a reduction in space requirements of facilities such as cabins.

2.2. System Boundaries and Fuel Supply Chain Scenarios

2.2.1. HFO Supply Chain

2.2.2. LNG Supply Chain

2.3. Transport Specifications

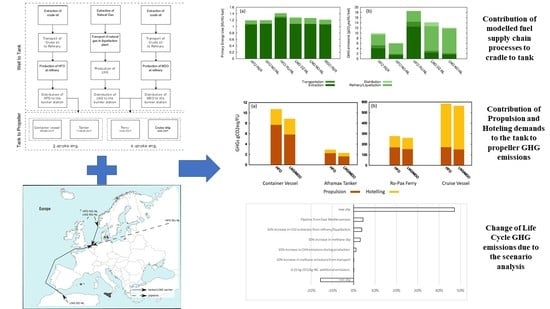

3. Results

3.1. Upstream (Well-to-Tank)

3.1.1. Contribution Analysis (Well-to-Tank)

- Treatment of natural gas (NG) which is a byproduct of crude oil. Onshore (Russia) NG is either burned or directly vented which leads to direct methane emissions while offshore it is processed and further used. As Figure 6 shows, the methane contribution in the onshore case is 87% higher than in the offshore case. Most of it (90%) is due to the direct venting, and 6% is due to differences in refining. In the offshore case, extraction and refining emit the same amount of methane.

- Capital equipment: the onshore plants have a lower productivity compared to the offshore platforms which implies higher infrastructure requirements per functional unit. Consequently, the corresponding GHG emissions are higher (approximately double).

3.2. Downstream (Tank-to-Propeller)

3.3. Total System (Well-to-Propeller)

3.4. Sensitivity Analysis

4. Discussion

4.1. Comparison with Other Studies

4.2. Policy Implications

4.2.1. The Need for Specific Fuel Supply Chains, Engine Types, and Operational Profiles

4.2.2. A Call for LCA-Based Environmental Performance Indicators

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sims, R.; Schaeffer, R.; Creutzig, F.; Cruz-Núñez, X.; D’Agosto, M.; Dimitriu, D.; Meza, M.J.F.; Fulton, L.; Newman, P.; Ouyang, M.; et al. Climate Change 2014: Mitigation of Climate Change. Contribution of Working Group III to the Fifth Assessment Report of the Intergovern- mental Panel on Climate Change; Edenhofer, O., Pichs-Madruga, R., Sokona, Y., Farahani, E., Kadner, S., Seyboth, K., Adler, A., Baum, I., Brunner, S., Eickemeier, P., et al., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2014; pp. 599–670. [Google Scholar]

- UNCTAD. Review of Maritime Transport Chapter 6: Sustainable Freight Transport—Development and Finance. United Nations Conference on Trade and Development, New York and Geneva, 2012. Available online: https://unctad.org/en/PublicationChapters/Chapter%206.pdf (accessed on 26 May 2020).

- Bouman, E.A.; Lindstad, E.; Rialland, A.I.; Strømman, A.H. State-of-the-Art Technologies, Measures, and Potential for Reducing GHG Emissions from Shipping—A Review. Transp. Res. Part D Transp. Environ. 2017, 52, 408–421. [Google Scholar] [CrossRef]

- Viana, M.; Hammingh, P.; Colette, A.; Querol, X.; Degraeuwe, B.; de Vlieger, I.; van Aardenne, J. Impact of Maritime Transport Emissions on Coastal Air Quality in Europe. Atmos. Environ. 2014, 90, 96–105. [Google Scholar] [CrossRef]

- Lin, H.; Tao, J.; Qian, Z.; Ruan, Z.; Xu, Y.; Hang, J.; Xu, X.; Liu, T.; Guo, Y.; Zeng, W.; et al. Shipping pollution emission associated with increased cardiovascular mortality: A time series study in Guangzhou, China. Environ. Pollut. 2018, 241, 862–868. [Google Scholar] [CrossRef] [PubMed]

- Russo, M.A.; Leitão, J.; Gama, C.; Ferreira, J.; Monteiro, A. Shipping emissions over Europe: A state-of-the-art and comparative analysis. Atmos. Environ. 2018, 177, 187–194. [Google Scholar] [CrossRef]

- EC. Reducing Emissions from Transport. Available online: https://ec.europa.eu/clima/policies/transport_en (accessed on 26 May 2020).

- Smith, T.W.P.; Jalkanen, J.P.; Anderson, B.A.; Corbett, J.J.; Faber, J.; Hanayama, S.; O’Keeffe, E.; Parker, S.; Johansson, L.; Aldous, L.; et al. Third IMO Greenhouse Gas Study 2014; The International Maritime Organisation: London, UK, 2015. [Google Scholar] [CrossRef] [Green Version]

- UNCTAD/RMT. Review of Maritime Transport 2016. United Nations Conference on Trade and Development, Geneva, 2016. Available online: https://unctad.org/en/PublicationsLibrary/rmt2016_en.pdf (accessed on 26 May 2020).

- IMO. International Convention for the Prevention of Pollution from Ships (MARPOL). Available online: http://www.imo.org/en/About/Conventions/ListOfConventions/Pages/International-Convention-for-the-Prevention-of-Pollution-from-Ships-(MARPOL).aspx (accessed on 14 July 2017).

- Cullinane, K.; Bergqvist, R. Emission Control Areas and Their Impact on Maritime Transport. Transp. Res. Part D Transp. Environ. 2014, 28, 1–5. [Google Scholar] [CrossRef]

- Marie Curie Actions (ITN, - Initial Training Network), G.A.N.; 607214. ECCO-MATE. Available online: http://ecco-mate.eu/ (accessed on 26 May 2020).

- IMO. Energy Efficiency Measures. Available online: http://www.imo.org/en/ourwork/environment/pollutionprevention/airpollution/pages/technical-and-operational-measures.aspx (accessed on 23 March 2018).

- IPCC. Summary for Policymakers. Climate Change 2013: The Physical Science Basis. Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Stocker, T.F., Qin, D., Plattner, G.-K., Tignor, M., Allen, S.K., Boschung, J., Nauels, A., Xia, Y., Bex, V., Midgley, P.M., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2013. [Google Scholar]

- ISO. ISO 14044:2006. Environmental Management—Life Cycle Assessment—Requirements and Guidelines; International Organization for Standardization (ISO): Geneva, Switzerland, 2006. [Google Scholar]

- Frydendal, J.; Hansen, L.E.; Bonou, A. Environmental Labels and Declarations. In Life Cycle Assessment: Theory and Practice; Hauschild, M.Z., Rosenbaum, R.K., Olsen, S.I., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 577–604. [Google Scholar] [CrossRef]

- Bonou, A.; Laurent, A.; Olsen, S.I. Life Cycle Assessment of Onshore and Offshore Wind Energy-from Theory to Application. Appl. Energy 2016, 180, 327–337. [Google Scholar] [CrossRef] [Green Version]

- Prabhakaran, P.; Giannopoulos, D.; Köppel, W.; Mukherjee, U.; Remesh, G.; Graf, F.; Trimis, D.; Kolb, T.; Founti, M. Cost Optimisation and Life Cycle Analysis of SOEC Based Power to Gas Systems Used for Seasonal Energy Storage in Decentral Systems. J. Energy Storage 2019, 26, 100987. [Google Scholar] [CrossRef]

- Brynolf, S.; Magnusson, M.; Fridell, E.; Andersson, K. Compliance Possibilities for the Future ECA Regulations through the Use of Abatement Technologies or Change of Fuels. Transp. Res. Part D Transp. Environ. 2014, 28, 6–18. [Google Scholar] [CrossRef]

- Hua, J.; Wu, Y.; Chen, H. Alternative Fuel for Sustainable Shipping across the Taiwan Strait. Transp. Res. Part D Transp. Environ. 2017, 52, 254–276. [Google Scholar] [CrossRef]

- Abadie, L.M.; Goicoechea, N.; Galarraga, I. Adapting the Shipping Sector to Stricter Emissions Regulations: Fuel Switching or Installing a Scrubber? Transp. Res. Part D Transp. Environ. 2017, 57, 237–250. [Google Scholar] [CrossRef]

- Adom, F.; Dunn, J.B.; Elgowainy, A.; Han, J.; Wang, M.; Chang, R.; Perez, H.; Sellers, J.; Billings, R. Life Cycle Analysis of Conventional and Alternative Marine Fuels in GREETTM; Argonne National Laboratory: Argonne, IL, USA, 2013. [Google Scholar]

- Brynolf, S.; Fridell, E.; Andersson, K. Environmental Assessment of Marine Fuels: Liquefied Natural Gas, Liquefied Biogas, Methanol and Bio-Methanol. J. Clean. Prod. 2014, 74, 86–95. [Google Scholar] [CrossRef]

- Sames, P.; Clausen, N.B.; Lyder Andersen, M. Costs and Benefits of LNG as Ship Fuel for Container Vessels. Available online: http://marine.man.eu/docs/librariesprovider6/technical-papers/costs-and-benefits-of-lng.pdf?sfvrsn=18 (accessed on 26 May 2020).

- Thomson, H.; Corbett, J.J.; Winebrake, J.J. Natural Gas as a Marine Fuel. Energy Policy 2015, 87, 153–167. [Google Scholar] [CrossRef] [Green Version]

- Moirangthem, K. EC-JRC Techical Reports. Report EUR 27770EN. Alternative Fuels for Marine and Inland Waterways. An Exploratory Study; European Comission: Brussels, Belgium, 2016. [Google Scholar]

- Alvarez, R.A.; Pacala, S.W.; Winebrake, J.J.; Chameides, W.L.; Hamburg, S.P. Greater Focus Needed on Methane Leakage from Natural Gas Infrastructure. Proc. Natl. Acad. Sci. USA 2012, 109, 6435–6440. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- IPCC. Climate Change 2014: Synthesis Report. Contribution of Working Groups I, II and III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Pachauri, R.K., Meyer, L.A., Eds.; IPCC: Geneva, Switzerland, 2014. [Google Scholar]

- Meyer, P.E.; Green, E.H.; Corbett, J.J.; Mas, C.; Winebrake, J.J. Total Fuel-Cycle Analysis of Heavy-Duty Vehicles Using Biofuels and Natural Gas-Based Alternative Fuels. J. Air Waste Manage. Assoc. 2011, 61, 285–294. [Google Scholar] [CrossRef] [PubMed]

- Bengtsson, S. Life Cycle Assessment of Present and Future Marine Fuels; Chalmers University of Technology: Gothenburg, Sweden, 2011. [Google Scholar]

- Corbett, J.J.; Winebrake, J.J. Emissions Tradeoffs among Alternative Marine Fuels: Total Fuel Cycle Analysis of Residual Oil, Marine Gas Oil, and Marine Diesel Oil. J. Air Waste Manage. Assoc. 2008, 58, 538–542. [Google Scholar] [CrossRef]

- Blanco-Davis, E.; Zhou, P. Life Cycle Assessment as a Complementary Utility to Regulatory Measures of Shipping Energy Efficiency. Ocean Eng. 2016, 128, 94–104. [Google Scholar] [CrossRef] [Green Version]

- Bengtsson, S.; Andersson, K.; Fridell, E. Life Cycle Assessment of Marine Fuels—A Comparative Study of Four Fossil Fuels for Marine Propulsion. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2011, 225, 97–110. [Google Scholar] [CrossRef]

- Schönsteiner, K.; Massier, T.; Hamacher, T. Sustainable transport by use of alternative marine and aviation fuels—A well-to-tank analysis to assess interactions with Singapore’s energy system. Renew. Sustain. Energy Rev. 2016, 65, 853–871. [Google Scholar] [CrossRef]

- Hansson, J.; Månsson, S.; Brynolf, S.; Grahn, M. Alternative marine fuels: Prospects based on multi-criteria decision analysis involving Swedish stakeholders. Biomass Bioenergy 2019, 126, 159–173. [Google Scholar] [CrossRef]

- Gilbert, P.; Walsh, C.; Traut, M.; Kesieme, U.; Pazouki, K.; Murphy, A. Assessment of Full Life-Cycle Air Emissions of Alternative Shipping Fuels. J. Clean. Prod. 2018, 172, 855–866. [Google Scholar] [CrossRef]

- Mountaneas, A.; Georgopoulou, C.; Dimopoulos, G.; Kakalis, N.M.P. A Model for the Life Cycle Analysis of Ships: Environmental Impact during Construction, Operation and Recycling. MARTECH 2014, 2nd International Conference on Maritime Technology and Engineering. Lisbon. 2015, pp. 829–840. Available online: https://www.taylorfrancis.com/books/e/9780429226663/chapters/10.1201/b17494-89 (accessed on 26 May 2020). [CrossRef]

- Harris, I.; Sanchez Rodrigues, V.; Pettit, S.; Beresford, A.; Liashko, R. The Impact of Alternative Routeing and Packaging Scenarios on Carbon and Sulphate Emissions in International Wine Distribution. Transp. Res. Part D Transp. Environ. 2018, 58, 261–279. [Google Scholar] [CrossRef]

- Nocera, S.; Cavallaro, F. Economic Valuation of Well-To-Wheel CO2 Emissions from Freight Transport along the Main Transalpine Corridors. Transp. Res. Part D Transp. Environ. 2016, 47, 222–236. [Google Scholar] [CrossRef]

- Trivyza, N.; Rentizelas, A.; Theotokatos, G. A novel multi-objective decision support method for ship energy systems synthesis to enhance sustainability. Energy Convers. Manag. 2018, 168, 128–149. [Google Scholar] [CrossRef] [Green Version]

- Mansouri, S.A.; Lee, H.; Aluko, O. Multi-Objective Decision Support to Enhance Environmental Sustainability in Maritime Shipping: A Review and Future Directions. Transp. Res. Part E Logist. Transp. Rev. 2015, 78, 3–18. [Google Scholar] [CrossRef]

- EC-JRC. International Reference Life Cycle Data System (ILCD) Handbook—General Guide for Life Cycle Assessment—Detailed Guidance, 1st ed.; Publications Office of the European Union: Luxembourg, 2010. [Google Scholar] [CrossRef]

- Frischknecht, R.; Jungbluth, N.; Althaus, H.-J.; Doka, G.; Dones, R.; Heck, T.; Hellweg, S.; Hischier, R.; Nemecek, T.; Rebitzer, G.; et al. The Ecoinvent Database: Overview and Methodological Framework (7 Pp). Int. J. Life Cycle Assess. 2004, 10, 3–9. [Google Scholar] [CrossRef]

- SimaPro Software v.7; Pre-Consultants: Amersfoort, The Netherlands, 2007.

- FuelsEurope. Fuels Europe Statistical Report 2017. Available online: https://www.fuelseurope.eu/wp-content/uploads/2017/06/20170628-Graphs_FUELS_EUROPE-_2017_vFinal_WEB.pdf (accessed on 26 May 2020).

- DNV-GL. THE FUEL TRILEMMA: Next Generation of Marine Fuels. Available online: http://www.green4sea.com/wp-content/uploads/2015/06/DNV-GL-Position-Paper-on-Fuel-Trilemma.pdf (accessed on 26 May 2020).

- DNV-GL. LNG AS SHIP FUEL. Available online: https://www.dnvgl.com/Images/LNG_report_2015-01_web_tcm8-13833.pdf (accessed on 14 July 2017).

- DNV-GL. Costs and Benefits of Alternative Fuels. Available online: https://www.dnvgl.com/maritime/publications/alternative-fuels-study.html (accessed on 15 June 2017).

- Dimopoulos, G.G.; Georgopoulou, C.A.; Kakalis, N.M.P. Modelling and Optimisation of an Integrated Marine Combined Cycle System. In Proceedings of ECOS, the 25th International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems, Perugia, Italy, 26–29 June 2012; Firenze University Press: Firenze, Italy, 2012; pp. 4–7. [Google Scholar]

- Mountaneas, A. Life Cycle Assessment of Pollutants from Ships: The Case of an Aframax Tanker; Faculty of Mechanical, Maritime and Materials Engineering, TU: Delft, The Netherlands, 2014. [Google Scholar]

- Balcombe, P.; Brandon, N.P.; Hawkes, A.D. Characterising the Distribution of Methane and Carbon Dioxide Emissions from the Natural Gas Supply Chain. J. Clean. Prod. 2018, 172, 2019–2032. [Google Scholar] [CrossRef]

- EC/INEA. Eastern Mediterranean Natural Gas Pipeline—Pre-FEED Studies. Available online: https://ec.europa.eu/inea/en/connecting-europe-facility/cef-energy/7.3.1-0025-elcy-s-m-15 (accessed on 26 May 2020).

- EC/ENERGY. Projects of Common Interest—Interactive Map, European Union. 2019. Available online: http://ec.europa.eu/energy/infrastructure/transparency_platform/map-viewer/main.html (accessed on 26 May 2020).

- Jaramillo, P.; Griffin, W.M.; Matthews, H.S. Comparative Life-Cycle Air Emissions of Coal, Domestic Natural Gas, LNG, and SNG for Electricity Generation. Environ. Sci. Technol. 2007, 41, 6290–6296. [Google Scholar] [CrossRef] [PubMed]

- Anderson, M.; Salo, K.; Fridell, E. Particle- and Gaseous Emissions from an LNG Powered Ship. Environ. Sci. Technol. 2015, 49, 12568–12575. [Google Scholar] [CrossRef]

- Solomon, S.; Intergovernmental Panel on Climate Change.; Intergovernmental Panel on Climate Change. Working Group I. In Climate Change 2007: The Physical Science Basis: Contribution of Working Group I to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2007. [Google Scholar]

- Laugen, L. An Environmental Life Cycle Assessment of LNG and HFO as Marine Fuels; NTNU: Trondheim, Sweden, 2013. [Google Scholar]

- Bengtsson, S.; Fridell, E.; Andersson, K. Environmental Assessment of Two Pathways towards the Use of Biofuels in Shipping. Energy Policy 2012, 44, 451–463. [Google Scholar] [CrossRef]

- IMO. MEPC.1/Circ.684: Guidelines for Voluntary Use of the Ship Energy Efficiency Operational Indicator (Eeoi); International Maritime Organisation: London, UK, 2009. Available online: https://gmn.imo.org/wp-content/uploads/2017/05/Circ-684-EEOI-Guidelines.pdf (accessed on 26 May 2020).

| Vessel Type | Container Vessel | Tanker | Ferry | Cruise Vessel | ||

|---|---|---|---|---|---|---|

| Main Engine | Engine type | (-) | 2 stroke DF engine | 4 stroke DF engine | ||

| Power output | (kW) | 1 × 37,680 | 1 × 14,940 | 2 × 3180 | 3 × 5300 | |

| Auxiliary Engine | Engine type | (-) | 4 stroke diesel engine | |||

| Power output | (kW) | 2 × 2205 | 1 × 2205 | 2 × 2205 | 3 × 2205 | |

| Cargo capacity | (-) | 4500 TEU | 105,000 ton | 800 passengers, 130 cars or 15 trucks | 2510 PAX | |

| Freight load factor to DWT/PAX for HFO (LNG) | (-) | 0.7 (0.69) | 0.75 (0.75) | 0.75 (0.72) | 0.81 (0.81) | |

| Dead weight | (DWT) | 67,567 | 114,829 | 1440 | 4042 | |

| Service speed | (kn) | 24.5 | 14 | 19 | 21 | |

| Property | Unit | HFO | LNG | MDO | |

|---|---|---|---|---|---|

| Lower Heating Value (LHV) | (MJ/kg) | 42.7 | 48 | 42.7 | |

| Density | (kg/m3) | 930 | 455 (NG 0.8) | 882 | |

| Emission factors | CO2 | (g/MJ) | 72.1 | 55.2 | 72.1 |

| CH4 | (g/MJ) | 0.029 | 0.045 | 0.029 | |

| N2O | (g/MJ) | 0.00187 | 0.001 | 0.00187 | |

| CO2-eq | (g/MJ) | 72.7 | 55.6 | 72.7 | |

| Scenario Name * | Extraction | Transport | Refinery (R)/Liquefaction (L) | Distribution to Bunker Station |

|---|---|---|---|---|

| HFO RU-NL | Onshore Russia (RU) | Onshore pipeline 5200 km | (R) Rotterdam | Barge 20 km |

| HFO NO-NL | Offshore North Sea (Troll field), Norway (NO) | Offshore pipeline from Troll field to Stavanger (293 km) Tanker from Stavanger to Rotterdam (462 km) | (R) Rotterdam | Barge 20 km |

| LNG DZ-NL | Onshore Algeria (DZ), Hassi R’Mel gas field | Onshore pipeline from Hassi R’Mel gas field to Arzew (DZ) (466 km) | (L) Arzew | LNG carrier Arzew-Rotterdam (1618 km) |

| LNG NO-NL | Offshore North Sea (Troll field), NO | Offshore pipeline from Troll field to Stavanger (293 km) | (L) Stavanger | LNG carrier Stavanger-Rotterdam (463 km) |

| Vessels and Operational Modes | Speed | Duration | Distance | Propulsion | Hotelling | ||

|---|---|---|---|---|---|---|---|

| (kn) | (h) | (km) | (kW) | (kW) | |||

| 2-stroke | Container vessel | High speed | 25 | 101 | 4574 | 31,059 | 3060 |

| Normal speed | 19 | 215 | 7461 | 23,751 | 3060 | ||

| Ballast transit | 13 | 222 | 5327 | 16,443 | 1530 | ||

| Manoeuvring | 10 | 134 | 2511 | 12,789 | 3130 | ||

| Port | 0 | 202 | 0 | 0 | 3060 | ||

| Tanker | Normal speed | 14 | 5358 | 138,922 | 10,039 | 717 | |

| Manoeuvring | 5 | 342 | 3167 | 3586 | 717 | ||

| Port | 0 | 0 | 0 | 0 | 1004 | ||

| 4-stroke | Ferry | Design speed | 3 | 19 | 106 | 5600 | 2660 |

| Manoeuvring | 1 | 7 | 13 | 2000 | 1900 | ||

| Port | 2 | 0 | 0 | 0 | 950 | ||

| Cruise vessel | Cruise 1 | 12 | 1033 | 22,957 | 4533 | 6396 | |

| Cruise 2 | 14 | 1339 | 34,718 | 6925 | 6396 | ||

| Transit 1 | 16 | 765 | 22,668 | 9998 | 6396 | ||

| Transit 2 | 18 | 574 | 19,135 | 13,823 | 6396 | ||

| Manoeuvring | 5 | 315 | 2917 | 408 | 6396 | ||

| Port | 0 | 3375 | 0 | 0 | 6396 | ||

| Vessel Type | % Change in Primary Energy Use When LNG Is Used Instead of HFO | % Change in GHG Emissions when LNG Is Used Instead of HFO | ||

|---|---|---|---|---|

| Propulsion Only | Propulsion and Hoteling | Propulsion Only | Propulsion and Hoteling | |

| Container vessel | −2% | −2% | −28% | −17% |

| Tanker | −7% | −6% | −31% | −21% |

| Ferry | −2% | 0% | −12% | −6% |

| Cruise vessel | −6% | −2% | −15% | −4% |

| Vessel Type | % Change in Primary Energy Use when LNG is Used Instead of HFO | |||||

|---|---|---|---|---|---|---|

| Using LNG (Supplied by Algeria) Instead of HFO Supplied by Three Alternative Sources: | Using LNG (Supplied by Norway) Instead of HFO Supplied by Three Alternative Sources: | |||||

| Average European | From Norway | From Russia | Average European | From Norway | From Russia | |

| Container | 1% | 1% | −6% | 0% | 0% | −7% |

| Tanker | −3% | −3% | −11% | −3% | −4% | −12% |

| Ferry | 3% | −3% | −3% | 2% | −2% | −4% |

| Cruise | −1% | −1% | −4% | −1% | −1% | −4% |

| Vessel Type | % Change in GHGs when LNG Is Used Instead of HFO | |||||

|---|---|---|---|---|---|---|

| Using LNG (Supplied by Algeria) Instead of HFO Supplied by Three Alternative Sources: | Using LNG (Supplied by Norway) Instead of HFO Supplied by Three Alternative Sources: | |||||

| Average European | From Norway | From Russia | Average European | From Norway | From Russia | |

| Container | −13% | −9% | −22% | −15% | −11% | −24% |

| Tanker | −19% | −15% | −29% | −21% | −17% | −31% |

| Ferry | −1% | 2% | −8% | −2% | 1% | −9% |

| Cruise | −2% | −1% | −5% | −3% | −1% | −6% |

| Tested Assumption and Reference Values | Developed Scenario | Reasoning |

|---|---|---|

| Methane emissions from LNG production | 10% increase | This life cycle stage is both impactful and uncertain. |

| Methane emissions from LNG transmission | 10% increase | This assumption was found to be a hotspot in other literature [36,38,51]. |

| Pipeline distance | 2700 km onshore 1000 km offshore | The scenario corresponds to the latest policy plans for a pipeline from east Mediterranean (EastMed project) [52]. The pipeline distance accounting for existing and new pipelines is estimated to the port of Rotterdam [53]. |

| Carbon emissions from refinery/liquefaction | 10% increase | This life cycle stage was found to be the most impactful accounting for more than 50% of CO2 emissions. Note that the CO2 intensity of liquefaction in the reference scenario (0.4 kgCO2eq/kg LNG) is close to the average (0.6 kgCO2-eq/kg LNG) reported in the literature [54]. |

| Carbon emissions from refinery/liquefaction | Increase by 0.15 kg CO2/kg NG | Following the example of [36], this scenario accounts for additional emissions due to venting and flaring. |

| Study | Vessel Type | Engine Type | Geographical Boundaries | % Change in GHG When LNG Is Used Instead of HFO | % Change in PEU When LNG Is Used Instead of HFO |

|---|---|---|---|---|---|

| Present study | Average of cruise and ferry | Four-stroke | Europe | −3% | −1% |

| Average of container and tanker | Two-stroke | Europe | −16% | −3% | |

| [25] | Tug | Four-stroke | Europe | −9% | N/A |

| [25] | Container | Two-stroke | North America | −16% | N/A |

| [57] | Ferry | Four-stroke | Europe | −2% | −27% |

| [23] | Ferry | Four-stroke | Europe | −7% | 4% |

| [30] | Ferry | Four-stroke | Europe | −10% | 9% |

| [58] | Ferry | Four-stroke | Europe | −16% | 10% |

| [36] | Not specified | Not specified | Europe | −8% | N/A |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seithe, G.J.; Bonou, A.; Giannopoulos, D.; Georgopoulou, C.A.; Founti, M. Maritime Transport in a Life Cycle Perspective: How Fuels, Vessel Types, and Operational Profiles Influence Energy Demand and Greenhouse Gas Emissions. Energies 2020, 13, 2739. https://doi.org/10.3390/en13112739

Seithe GJ, Bonou A, Giannopoulos D, Georgopoulou CA, Founti M. Maritime Transport in a Life Cycle Perspective: How Fuels, Vessel Types, and Operational Profiles Influence Energy Demand and Greenhouse Gas Emissions. Energies. 2020; 13(11):2739. https://doi.org/10.3390/en13112739

Chicago/Turabian StyleSeithe, Grusche J., Alexandra Bonou, Dimitrios Giannopoulos, Chariklia A. Georgopoulou, and Maria Founti. 2020. "Maritime Transport in a Life Cycle Perspective: How Fuels, Vessel Types, and Operational Profiles Influence Energy Demand and Greenhouse Gas Emissions" Energies 13, no. 11: 2739. https://doi.org/10.3390/en13112739